Build #29: EXT65

Over the past several months, I’ve been living with the 1800 layout, and have really grown to love it.

Relative to a full-size, nothing I use is lost with 1800, and I gain valuable ergonomic real estate

for the mouse.

But that doesn’t mean there’s no room for improvement. Even though I’m right-handed, I can appreciate the idea of moving the numpad into a southpaw configuration, and turning the primary portion of the board into a 65, dropping the little-used F-row along the way. Which is more or less how you end up with the layout on the EXT65, the second board from AEboards. As soon as I saw this board for the first time, I knew I had to get in, just to give this layout a shot.

In unrelated news, Chewwy of Mechs on Deck came up with a new and interesting tactile frankenswitch, which he dubbed a Zyko - a combination of a V2 Zealio bottom, a Halo stem, and a Panda top. After assembling one from spare switches to form an impression, I found the tactility to be more rounded than a Holy Panda, but with a crisp and sharp sound, both of which appealed to me. I knew immediately I wanted to try this combination on a full board. Why not the EXT65? Why not, indeed.

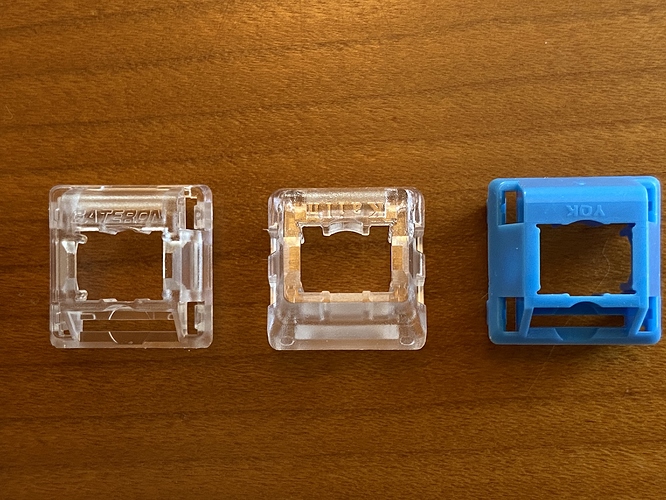

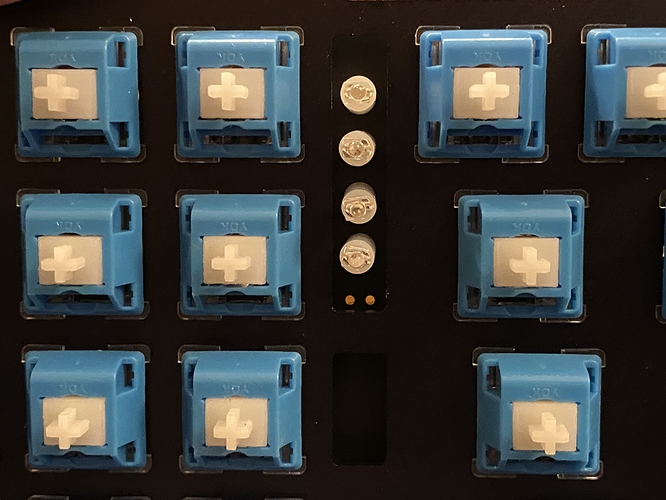

Let’s start with the Zykos. I used the following switches for the raw ingredients: V2 Zealios on the left, Halo Clears in the middle, and YOK Polar Pandas on the right.

Before we dive in and assemble some Zykos, it’s worth talking about housings for a bit. Here are the top housings for a V2 Zealio, a Halo, and the Polar YOK. From this side, other than the different side locking mechanisms on the Halo (Kailh), the geometries are relatively similar.

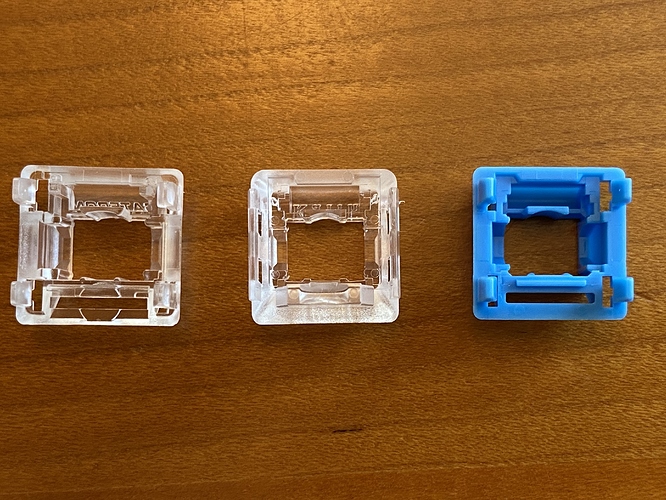

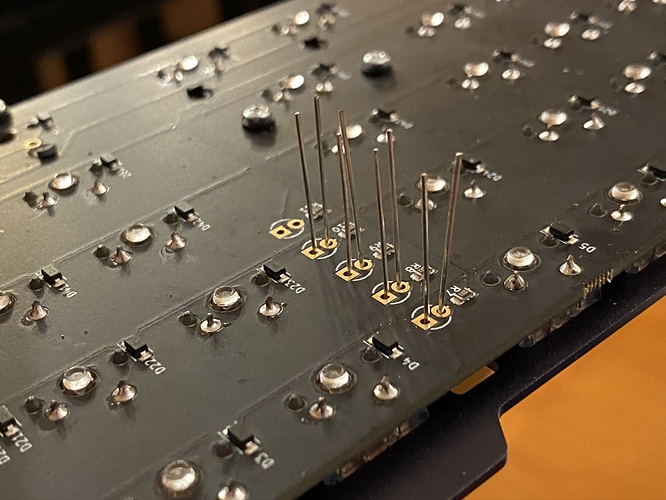

From the other side, however, there is an important difference. Looking at the photo below, do you see those two pins protruding up from Zealio top housing, above the ‘G’ and ‘N’ in “Gateron”? Those pins are what keep the switch leaf in place when it is fully assembled. Looking over at the Polar YOK housing, you’ll notice that no such pins exist. The implication is that the leaf in a Zyko is going to be free to move upward in a way it wouldn’t be in a stock V2 Zealio. This isn’t really a problem during Zyko assembly or lubing, but it can be a problem during the build if you’re not careful. We’ll come back to this issue.

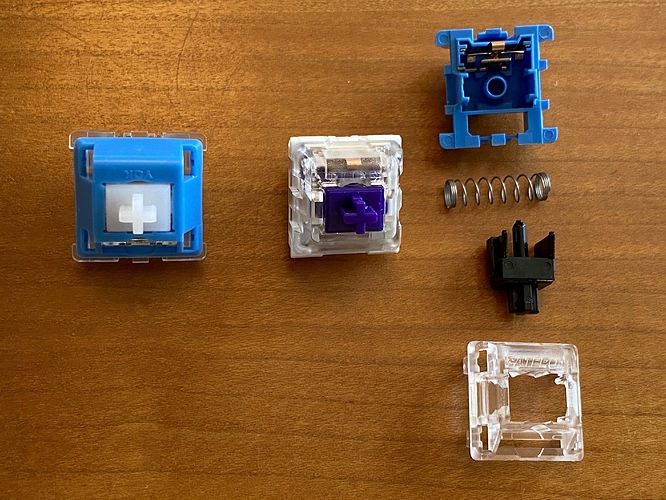

Taking the parts from the three switches I showed you earlier, here are the results of the crossbreeding. On the left, a Polar Zyko; in the middle, a Halo housing, a Zealio V2 stem, and a YOK spring as leftovers, in what I’m going to call a “Zykout”, and on the right, the leftover parts that we can’t directly use - a Polar YOK base and stem, a Halo spring, and a Zealio V2 top. To me, the “Zykout” feels like a slightly Halo Clear in terms of tactility, so in theory, it’s probably usable with careful lubing and perhaps filming as well, which makes building Zykos somewhat more palatable from a price perspective - at least you get two switches out for every three switches in…

I imagine most people would just lube the Zykos as they build them, but I’m not most people. When I’m frankenswitching, I prefer to build the frankenswitches first, without lube, and then open them up and lube at a later date when I’m actually ready to use them. I’d argue that when you’re working with three switches, this is actually preferable, to avoid mistakes in doing all of the necessary part swaps. But YMMV, as always.

At the risk of providing far too much detail, here are the steps I follow when assembling Zykos. I generally work with switches in batches of 15-20, so I can take frequent breaks and not lose my mind. Here, I’ve started by disassembling V2 Zealios, putting the bottoms in a lubing station, and reserving the stems for later.

Next up, I disassemble the Polar YOKs, reserving the tops and springs, and discarding the remaining YOK parts. OK, I don’t really throw away the stems and bottoms - I put them in Ziploc bags, in the event a use for them ever materializes.

In the third step, I disassemble the Halos, putting their stems on the V2 Zealio bottoms, and reserving their tops. I know some people would prefer the Halo springs to the YOK springs for the “Zykouts”, but I find the Halo springs a bit too stiff for my taste, and I’ll be lubing springs to deal with ping in any case, so the leftover Halo springs get the ziploc treatment. At this point, all of the parts for Zykos and Zykouts are now ready for assembly.

From here, there’s really only one way to put everything back together. The YOK springs go on the Halo bases, and the Zealio stems go on the YOK springs:

After that, the YOK tops go on the Zealio bottoms, and the Halo tops go back on the Halo bottoms, completing one batch of Zykos and Zykouts:

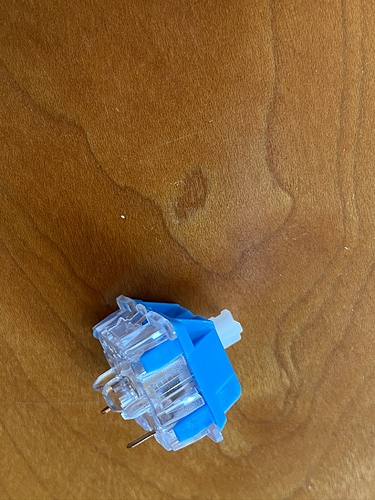

There is one little gotcha I want to highlight at this stage, before we actually try using Zykos on a board. As you assemble Zykos, you may find that the sound of the switch is not crisp and the tactility is not sharp. If this is the case, check the fit of the YOK top to the Zealio bottom. It’s highly likely you’ll see something like this, where one side of the YOK top has not fully snapped into place:

In that case, just press down the YOK top with more force until it snaps firmly into place:

At your leisure, lube as you see fit. For me, it ended up being my usual 104 tub-lubing on the springs, coupled with 3203 on the three non-leg sides of the stem, to preserve as much of the tactility and feel of the Zyko as possible. These days I haven’t been lubing the housing of the switch, instead taking care to carefully lube all possible housing/stem contact surfaces on the stem (other than the tactile side of the stem, of course).

Enough about Zykos for now. Let’s talk about the EXT65!

As usual, the build properly begins with stabilizer work, which in turn depends on our choice of layout. For the EXT65, the three 2u numpad keys and the backspace key can all be split into 1u keys, but I opted to keep all of these as 2u keys, which meant I needed to prep one 6.25u and six 2u stabilizers. After clipping and lubing, here we are:

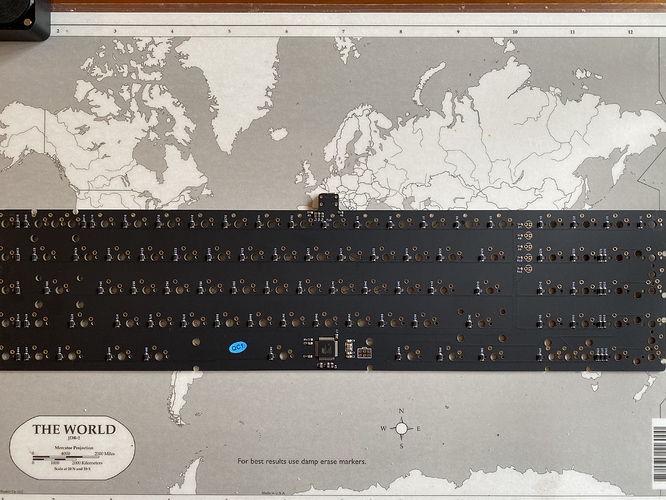

The EXT65 PCB is a matte-black affair, with USB-C connector on the top side:

On the bottom, we see LEDs for Num Lock, Caps Lock, and Scroll Lock (NCS), as well as two more LEDs - one to indicate when we are switching QMK layers, and another which as far as I am aware is not actually used, perhaps a holdover from an earlier design iteration.

Because this isn’t a swiss cheese PCB, it’s pretty obvious where the stabs go, and easy enough to install them.

Even though I don’t think there was any real danger of screw-in stabs shorting pads on this PCB, whenever I see that a screw might make contact with a pad, I prefer to use cloth or nylon washers to completely eliminate the possibility. In the following photo, you can see one of the washers making contact with a pad on the PCB.

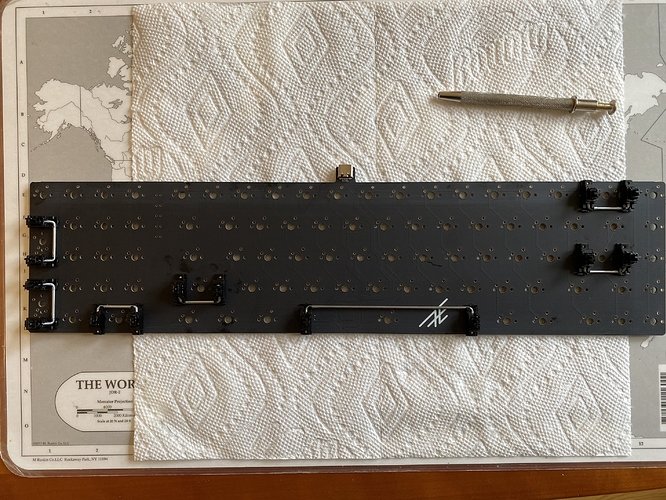

It’s time to start mounting and soldering a few switches on the board, and time for our first look at the plate. Notice the eight trapezoidal tabs on the plate - these will rest on gaskets in the bottom of the EXT65 housing.

At this point, I want to come back to the leaf issue with Zykos. As I was pushing switches into the plate, and pushing switch pins through pad holes, I noticed that several pins were only partially protruding through the PCB pad holes, even though the switches appeared to be properly seated. Because the Zealio leaves are not backstopped by any pins in the YOK top, as they would have been with a Zealio top, the leaf is pushed upward when any resistance is encountered while mounting the switch. However, I also found that the leaf was not damaged - just pushed out of alignment. In every case, I was able to “pull” the short pin up with a pair of needlenose pliers, reseating the leaf in its proper position.

Having seen a lot of reports on the fragility of Zykos and the ease with which they can be damaged during installation, I spent a lot more time than I usually would making sure that each switch was properly aligned with pin holes before applying pressure. I suspect that’s why none of my switch leaves appeared to be bent, and hence a gentle tug on a switch pin with pliers was enough to reseat the leaf. I can easily imagine that if the switch wasn’t properly aligned from the beginning, it would be very easy to damage the leaf (and the switch) beyond repair. If you try Zykos, I strongly recommend making sure you properly align each switch with the plate hole and PCB holes before pressing down to mount the switch, and using needlenose pliers to tug a switch pin back into place, if necessary, after the switch has been mounted. Again, YMMV.

After a more arduous switch mounting process than usual, and after soldering the remaining switches, we have a complete PCB/plate assembly, at least as far as switches are concerned. Note that once you’ve got the Zykos soldered into place, and you’ve tested with Switch Hitter to make sure you don’t have chatter, you’re good.

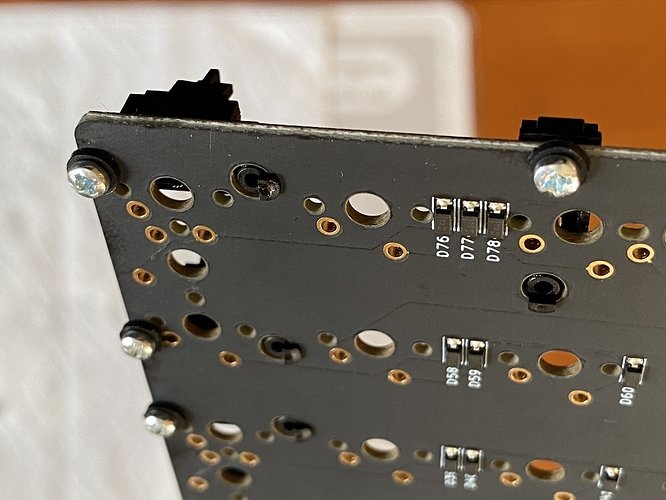

We still have to install LEDs for NCS and Fn indicators. 1.8mm LEDs work fine here, but you will want to use the (included) spacers to make sure that the LEDS are inside cutouts on the case top, so that light won’t bleed from one indicator to another. I found it easiest to proceed in the following order - put the spacers on the LEDs, put the LEDs on the PCB, and then fit the case top to the board before soldering the LEDs in place, to ensure that the spacers are seated properly.

On this PCB, the long legs of your LEDs should go through the circular pads, not the square ones.

Our first look at the two halves of the EXT65 case. The “Aegis Navy” color is gorgeous, and the ano is very clean and smooth. This picture does not do it justice. Note that the EXT65 supports negative-typing angle, if you’re into that - just reverse the top during installation. I’ll try that at some point, but I’m 99% sure that won’t be my jam; I’m here for the layout (well, the cosmetics too).

The EXT65 was a 50-board run (well, actually, 54, but more on that in a future build log). Here we see the EXT65’s gasket mounting solution - adhesive pads are placed in trapezoidal cutouts on the base, and the trapezoidal tabs of the plate rest on these pads. The entire PCB/plate assembly is held in place by compression once the two halves of the case are screwed together.

The EXT65 came with four sets of adhesive gasket pads, each of a different material - in decreasing order of hardness, rubber, silicone, Poron, and foam. I opted for Poron, as it seemed to have enough give to be interesting. I haven’t yet experimented with other gasket materials.

With eight Poron gaskets in place, we can screw the whole thing together. Here’s the completed board, sans keycaps:

After a couple of days using the board, I found that the Zykos paired the immediate, rounded bump of a Zealio V2 with the clack of a Holy Panda, which, feel-wise, hits a very nice spot for my personal preferences. Sound was another matter; I expected a loud clack from the progeny of a Zealio V2 and Holy Panda, but I wasn’t expecting that much clack. These are loud switches. So, I ended up doing a quick Sorbothane treatment between the PCB and case to take the edge off of the clack. A few small pieces do the job, at least for me. I left the protective plastic on the Sorb to guard against staining that beautiful anodization, and after a quick test fit, we’re getting about the right level of compression on the switch pins.

Lessons learned

- Left-handed boards are definitely worth right-handed attention. I’m still getting used to having the numpad on the left, but it really is a nice way to gain ergonomics without sacrificing functionality.

- I was somewhat skeptical that gaskets on the bottom case only would be enough to eliminate metallic case sounds, but these gaskets do the job. Sorbothane struts between the PCB and plate might further attenuate the sound, but I don’t believe they would alter the tone substantially.

- Zykos deliver a really nice rounded tactility with crisp response - I completely understand the appeal on the feel front. On the sound front, the jury is out. If you like that Holy Panda popcorn popper sound, these are for you. I think I’d like to try more aggressive lubing next time to dial back the sound a bit.

The anodization and “Aegis Navy” color on this board is gorgeous, but not at all easy to capture. Nevertheless, if you let your eye run along the bezels of the EXT65 in the photos below, I think you will have at least some idea…

Specifications

case: AEboards EXT65

- bead-blasted 6063 aluminum, "Aegis Navy" anodization

case dampening:

- eight Poron gaskets

- four strips of 1/10" 40 Duro Sorbothane between PCB and case

PCB: EXT65 (USB-C)

plate: 1.5mm "Aegis Navy" anodized aluminum

plate/PCB dampening: N/A

stabilizers: GMK PCB screw-in

- 1x6.25u, 6x2u

stabilizer mods: clipped and lubed with SuperLube

switches: 84x 67g Polar Zykos

- 84x 67g V2 Zealio bottoms/leaves

- 84x Halo Clear stems

- 84x YOK Polar Panda tops

switch mods:

- springs tub-lubed with Krytox GPL-104

- stems hand-lubed with Tribosys 3203

- no housing lube

keycaps:

- GMK Sky Modo alphas

- GMK White on Black mods

- AE x RAMA black aluminum with white infill

HxWxD (without caps or feet): 1.13" x 16.13" x 4.63"

HxWxD (without caps): 1.19" x 16.13" x 4.63"

HxWxD: 1.5" x 16.13" x 4.63"

assembled weight: 1.804 kg (3.98 lb)