I’ve never ordered a custom PCB myself though I know there are some known best practices and constraints.

I don’t know what to do when it comes to laying tracks that connect to pads.

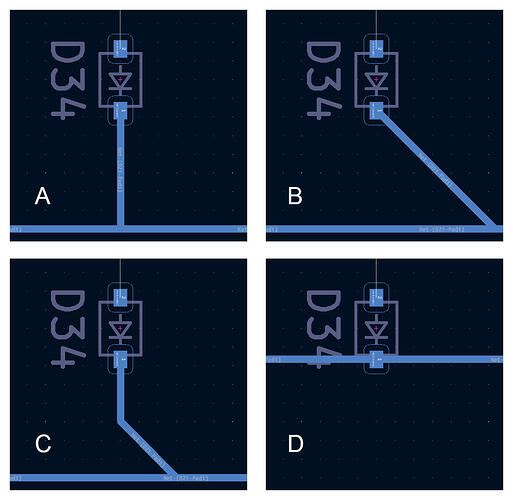

I have this - I belive- very simple decision to make. Which is the correct way in this picture?

All 4 are good electrically but a good thing is always try not to have 90% angled tracks for high speed traces.

In your case no high speed traces but it also nicer to look at.

In general I avoid A and B and uses C and D.

What about manufacturing point of view?

I’ve read 90º are known to be – or have traditionally been – a possible point of manufacturing errors so I was also considering what other issues might these examples raise from that point of view too.

Would your answer be the same for PTH pads?

Thanks for answering!

I don’t know if this could provoque manufacturing errors, but no PCB manufacturer are asking to not use 90% angled tracks.

And yes, I do the same for THT.

Well, that solves my question, and thanks to you comment about high speed signals, now I can learn about that as a side task which in time will result in a broader understanding of what I’m doing and why.

Once again, thank you!