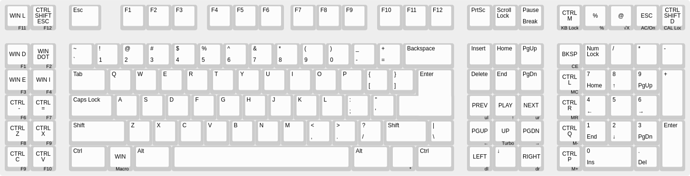

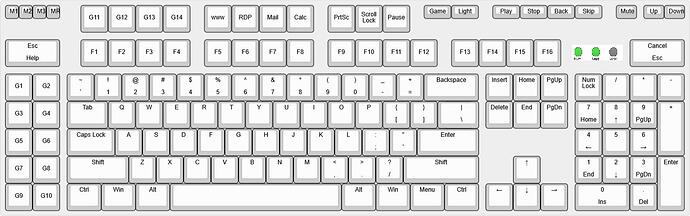

So that is indeed a big fella. It’s not impossible, though, not by a long shot. If you can live without addressable lighting (i.e. none at all, or you just turn it on), it looks like you need up to 28 GPIO pins to code it using the standard toolsets and “usual suspect” hardware, and fortunately, that’s about where they top out. There are other tricks like Japanese matrix wiring and shift registers that could reduce that quite a bit, but the usual method is to wire buttons into a matrix that has diodes along one axis to prevent ghosting, and the max number is the square root of total keys, times two, rounded up if it’s not an integer. Then you’d need a pin for each lock indicator, and 2-3 for a knob.

A printed circuit board of the cheapest type would require a spot for a large format MCU, 140ish diodes, and a few resistors. Once designed, it would be about $60-$200 to have the minimum order of 5 of them made by the cheapest vendor and shipped to the US (thanks, unpredictable but likely huge tariffs!). You could have much of it preassembled for more, but I’ve never done that myself, or even priced it out; I don’t think it would go past double for a keyboard PCB though. Handwiring is potentially less reliable, but it’s robust in the sense that it’s easy to fix. It can be done for the cost of tools components, and wire; occasionally (though not with MY boards, LOL) it can verge on being a work of art.

A switchplate is nominally optional, but unless you do a very specific type of mount, I’d say it’s close to mandatory for a board this size. I haven’t priced these out recently, but on this size figure another $100 at least. Lots of options in this space, though. Don’t take that number as gospel. Aluminum, FR4 (circuit board material), or various plastics could all work. The cost is more in the setup and machine time than the material.

That leaves you with a case. a CNC’d case for a board this size will be extremely expensive, having to be a bespoke design and quite large. My initial guess is that prototyping one would be around $500 at an absolute minimum, and maybe a good bit more these days, though I’d be extremely happy to be told I was wrong. 3D printing could also be an option, and is probably the only other thing that could get you close to the aesthetic sense of the Logitech, but you’re looking at either the “traditional” 3D printed surface, some creativity to design for the newer surfacing techniques off the machines, or a lot of post-processing, which can get pricey if someone is doing it for you.

Stacked laser-cut acrylic is potentially a more attractive option, and also opens up the number of vendors/makers who can help you. You could also use the same vendors you selected for your plate and get something that could be stacked or bent and maybe have some sort of cushioned mount. Neither of these will LOOK like the Logitech though. There’s also the super simple “sandwich” idea, which is barely a case at all, but rather some structural means of separating the switch-plate and a base plate; these typically leave the sides of the switches exposed, which is still fairly common in gaming boards, but less so in “enthusiast” boards.

Your layout is mostly fine, though no “keyboard” switches will really fit under the smaller buttons you have, and the trend in the hobby is to simply make everything a normal sized key. I assume you’d like volume in a rotary encoder, and most of the more common ones will also serve as a button that can be used as mute (or anything you like, but that’s common). You could run into some issues finding keycaps with the right legends for your oversized escape keys, but you were smart to pick 2U, since at the very least the right size and shape for that placement should exist.

Spitballing again, but I’d say the absolute bare minimum BOM for a hand-wired proof of concept for this board, looking a bit like a flat version of older Hyper7 boards, and using commodity caps and switches, and completely excluding anyone’s time, might be around $300, looking something like this:

- Keycaps, $40 (some cheap set plus a set of blanks)

- Switches, $40 (even for cheap ones, because you need a lot of them)

- Switchplate, $100

- Baseplate, $60

- Standoffs, wire, diodes, resistors, LEDs, MCU, solder, etc., $40

- Feet, $20 (you probably don’t want 0-degree typing angle for this hombre)

You’d probably add $100+ (as discussed) to change to a simple soldered PCB that piggybacks the MCU, or some amount more for a properly designed one with integrated MCU, and more again if you need hot-swap, though you could erode the $40 for other supplies somewhat. You could enclose the sides with something laser-cut or 3D printed for maybe another $30-$50 if you design it with an eye towards inexpensive fabrication. This would NOT look like a G910, but it would bring your layout into the real world. The look can be nce enough, but it’s very specific to what it is. “Pretty” gets expensive really fast.