With my Filco mod reaching diminishing returns and my Holy Pandas on their way (finally!), I finally have the heart to disassemble their target board, a Ducky One 2 TKL. I was quite scared to mess it up, and was putting it off, since my digging told me that this is not an easy case to open ([鍵盤] Ducky One 2 開拆 - 看板 Key_Mou_Pad - 批踢踢實業坊, [鍵盤] Ducky One 2 拆殼問題 - 看板 Key_Mou_Pad - 批踢踢實業坊, zFrontier 装备前线).

You know the adage about creating the content you wish existed when you needed it? Here’s my attempt to contribute. The tag “guide” might be overstating the expertise since I did break 2 clips and bend others. However I do want to share my lessons and some pictures for anyone that might be interested in opening up this board.

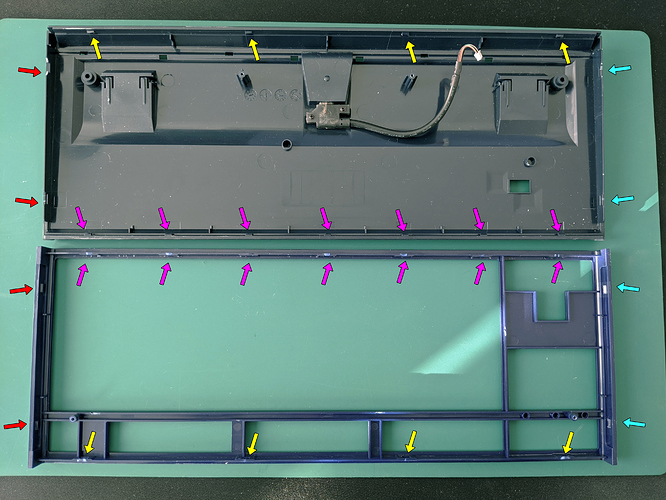

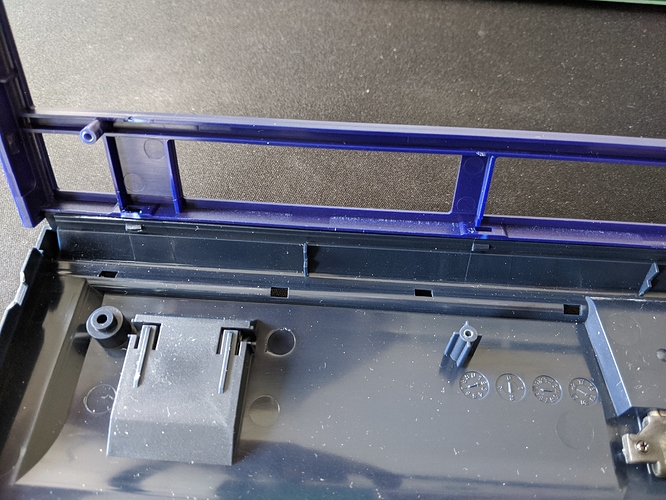

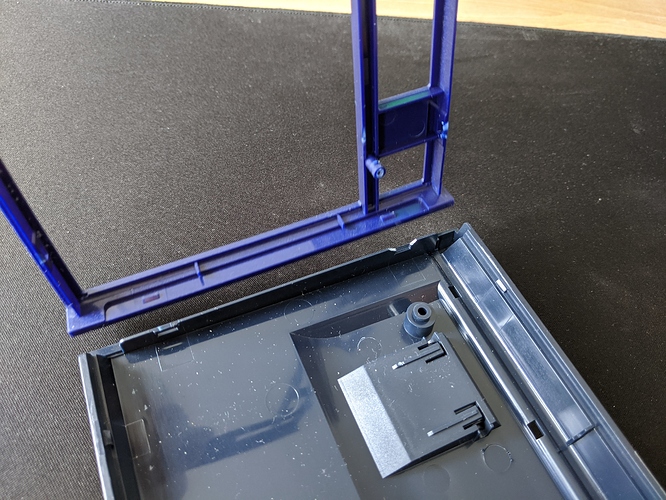

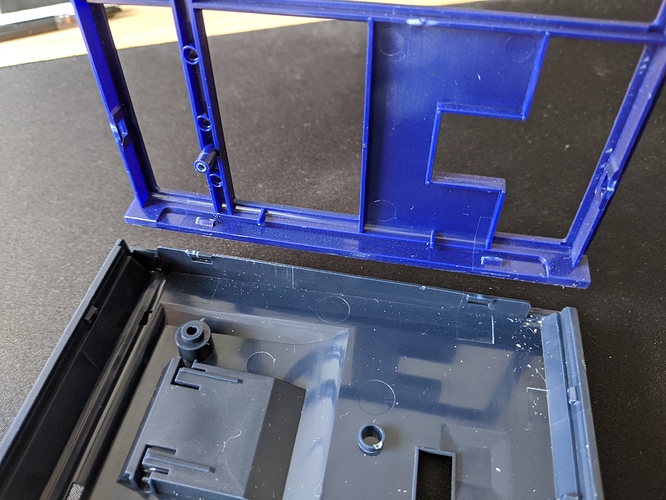

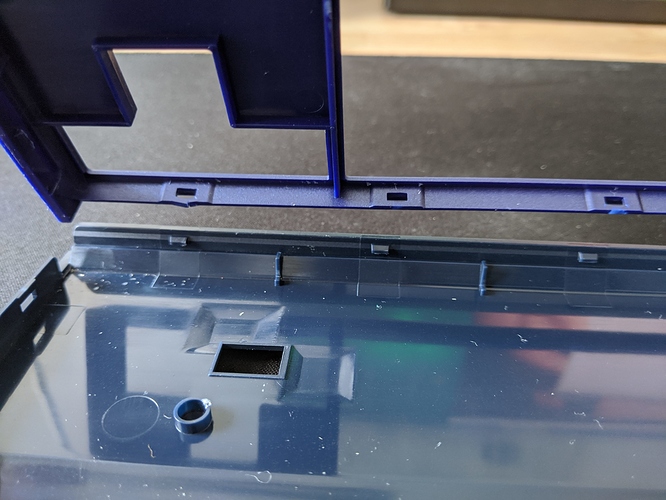

Specifically I wanted to get a better idea for where the clip pairings are (horizontal positions to pry), and which the housing has the tooth / hole parts (which vertical direction to pry). As you can see the North/South sides are one way and the East/West sides the other. The last link above showed this already somewhat, but the pictures are overexposed, and I didn’t feel super well informed. Plus they are from the 100% keyboard whereas this is the TKL.

First off: Don’t forget to undo the 2 screws from the bottom. No brainer, right? But I seriously forgot this, was too eager to work on the housing. I loosened the North side (start from the center!) and was wondering why the East side was giving me such a hard time – only then I remembered the screws. Unscrewing literally allowed the loose corner of the top housing to almost pop open by itself.

Ironically, I still broke 2 tabs after that, probably because I then half-expected the West/South sides to also pop up more easily. They did not. Be patient and stay gentle til the end.

Anyways, here are detailed views of all sides:

North / West:

North / East

West:

East:

South side: (note: the pictures seem like repeating the North side and maybe a little confusing; I rotated the housing for easier handling)

South / East

South / center:

South / West:

I don’t know yet if they snap back tightly. But I’ll only find out when everything is finished – there’s no way I’d stress the plastic more and risk breaking more clips just to test it. As you can see, many are already bent and/or whitened.

I’ll report back when the mod is completed… in a month maybe?

…and something I’ll only notice in the future

…and something I’ll only notice in the future