So I’ve been wanting to make some wrist rests. They seem like they would be straight-forward enough to make, I could apply my designer skills and sensibilities to them to make some interesting pieces, and it gives me an excuse to buy a table saw. Plus it sounds fun. I’ll be documenting my journey here.

Experiment 0

This rest was really just created to get my bearings and learn how to operate the saw. I took a 12" x 72" x 3/4" piece of pine that I had originally bought for painting on, but had to drill random holes into to patch the backyard fence. I cut a 12.5" x 3" piece (12.5" being the width of my KBD67), then cut a 45 degree angle down the front and 30 degrees on the sides, really just to see how they would look.

The result is a pretty terrible wrist rest. The cuts are ugly, the angles are awkward, and your hands slide off the edge while trying to use it. I painted it anyway just to get reacquainted with finishing wood, as it’s been awhile since I’ve played carpenter. Despite this rest being completely useless, it helped me figure out what I wanted my next creation to look like.

Experiment 1

I sat down a did a little research on what rests were on the market currently. Glorious seems to be the only company that offers consistent product targeted toward the mech community. There are numerous sellers on Amazon, of course, but most offer generic padded rests. Etsy was more promising, with sellers there offering all manner of handmade rests, some of which looked absolutely fantastic. What I didn’t see in my brief search however, were any offerings for colorways that might match existing keyboards. It’s there that I may have a niche I can fill.

But more on that later. I still need to figure out my shape. From my research, I found there are 4 main shapes: flat, angled, rounded, and angled into flat, which I’ll refer to as ridged. Rounded I definitely don’t have the equipment for. Ditto for a straight angle, which seems to require a planer. That leaves flat and ridged.

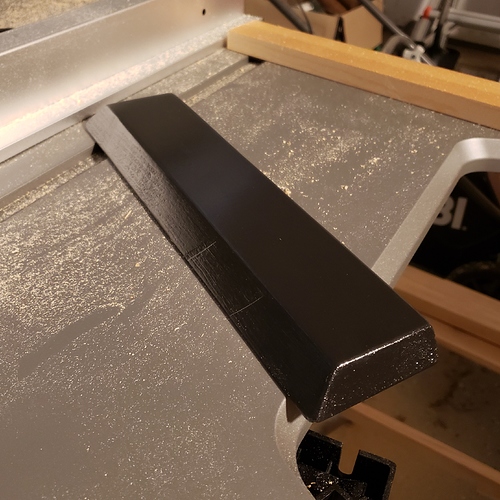

I took the same 3/4" pine I used for E0 and cut a 12.5" x 3.5" piece, then set the fence to 3/8" and the angle of the saw to 13 degrees and cut the piece while standing it on its narrow side. Then, for aesthetic appeal, set my miter saw to 30 degrees and angled the short sides. The result is this:

Not a bad look! Upon trying it out, I immediately found it much better than E0, though the 13 deg angle felt slightly too steep. Also I didn’t take into account that beveling the sides would shrink the visual footprint of the piece, even if the physical footprint was the same width as the keyboard. Still, it’s a reasonable candidate, though I want to continue prototyping.

.

.