Build #14: Tofu tasting (1st course: acrylic)

In an earlier build log, I mentioned that my “workshop” is in the corner of an unheated garage. This makes it difficult to do much soldering in the winter months. During the worst of the cold spells, I hunkered down and did a bunch of switch modding. For this build, the first in a series of builds with various Tofu cases and PCBs, I wanted to actually use some of the fruits of my labors. Introducing: the Holy GSUS!

For those who haven’t been following the Holy Panda saga, I’m not going to replay all of the drama here - you can use this post to review. For our immediate purposes, the following suffices:

- A Holy Panda is a switch assembled from the stems of Halo switches (tactiles), and everything else from an Invyr Panda (linear). It is very tactile and loud. Up until recently, the market price for these has been quite high, due to the scarcity of the Panda switches.

- A Holy GSUS is also assembled from the stems of Halo switches, but everything else comes from a Bsun GSUS, a clone of the Invyr Panda. While this was a one-off run, it is now possible to find other Panda clones on the market.

For lubing, I went with manual application Tribosys 3204 on the housing rails, slider stem, and slider sides; I didn’t apply any lube to the tactile legs. I used roughly 1mL per 65 switches. For the springs, I tub lubed with Krytox GPL 104, about 1 drop of lube for every 7 springs. The results are below - a lubed batch of Holy GSUS on the left, and on the right, an unlubed batch of the Unholy GSUS - GSUS stems with Halo housings and springs, the unused byproduct of the Holy GSUS assembly process.

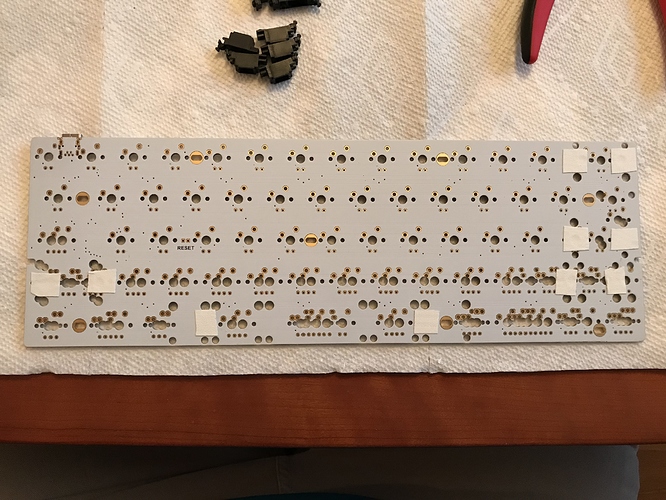

I had been using electrical tape for the stabilizer bandaid mod, and then silicone pads, but I found the silicone pads to be a bit finicky in recent builds. Specifically, if they aren’t centered under the stabilizer housing, the housing can tilt slightly to one side when it’s screwed into place atop the silicone pad, leading to problems with stabilizer function. So, on to alternative #3: gaffer tape, a good cloth tape. Here’s the bandaid mod on the DZ60 we’re using for this build:

Whenever I build with a DZ60, I use nonconductive washers for all of the screws - it’s not strictly necessary for all of them, but for at least one of the screw holes, the screw can short out a couple of pads on the board, and once I’ve used a washer for one screw hole, my OCD kicks in and I’ve got to use washers for all of them. Here they are on GMK stabilizer screws:

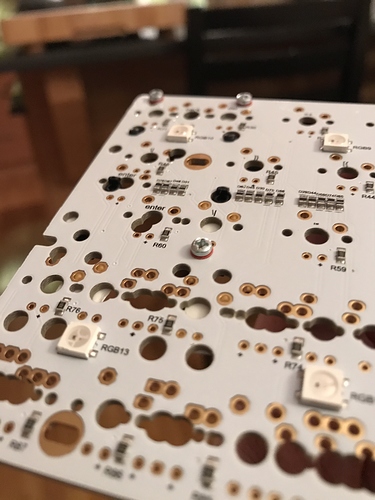

And here’s the one that has caused me short problems in the past, the stab screw for the enter key, just to the right of R60 (you can see a pad poking out from underneath the red washer):

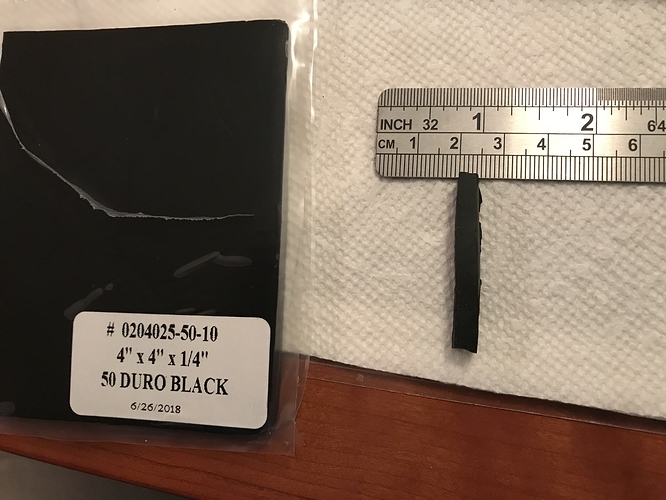

With bandaid modded, clipped, and lubed stabs in place, it’s time to address PCB/plate dampening. For a typical 1.5mm plate, I’ve been finding that 4mm of Sorbothane between the plate and PCB is just about right for removing plate pings. Because 4mm thick Sorbothane doesn’t seem to be readily available, I’ve been hand-cutting 4mm-wide strips from a 0.25" thick sheet of Sorbothane.

Once I have the 4mm strips, I’ll cut off small pieces and rotate the pieces sideways before sandwiching them between the plate and PCB, to achieve the desired 4mm compression. I put the pieces wherever I can fit them without getting in the way of screw holes or switch cutouts - on this plate, that means the area right above LShift, the little area between Return and the screw hole above it, the same area on the left side of the board between CapsLock and the screw hole, and on either side of the space bar. Not much Sorbothane, but you don’t need much to obtain good results.

Before going any further, this is a good time to get corner switches in, and check stabilized keys for any issues.

Now, at this point we could just mount switches, solder, screw the PCB/plate sandwich into the case. In fact, I did this during a brief warm spell (50F in the garage, fire up the iron!), because I wanted to find out: how loud would a hyper-tactile switch be, in a hard sound-reflecting plastic case?

It turns out, it’s loud. Very loud. If you’re a hard typist, the combination of acrylic and Holy Pandas will be like having a batch of popcorn popping under your fingers. Even if you love the click and clack of a noisy switch, you might find this to be just a little too much of a good thing.

So, I opened it back up, and set about dampening the case. If you’ve been following my logs at all, you know my standard approach involves Sorbothane. However, for this build, we have to be careful. The case we’re using is a frosted acrylic Tofu, and a big reason for using this case is to show off and diffuse all of the RGB underglow from the DZ60. So, if we use Sorbothane, we need to make sure we’re not blocking the LEDs. Easy. However, Sorbothane is black, and aside from light absorption, black is going to look somewhat ugly through a frosted translucent case.

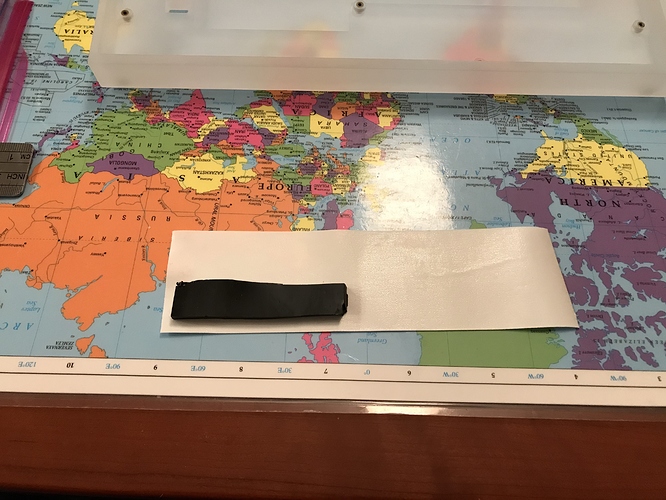

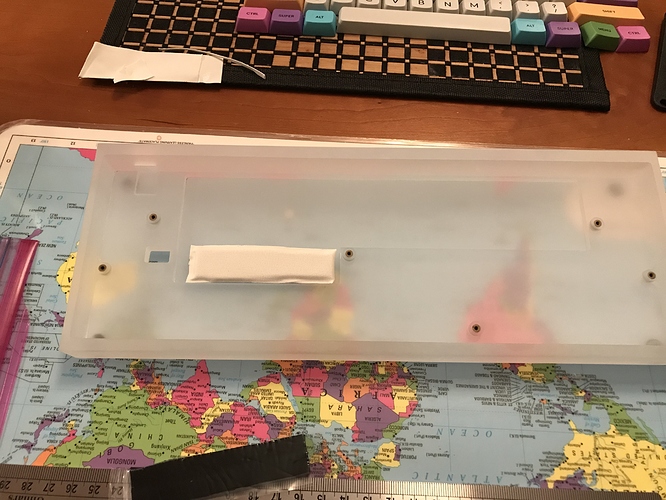

To solve both problems, I did the same trick that I used on the Ocelot build - I wrap the Sorbothane in white gaffer tape. After cutting a section of Sorbothane to size, I place it on the adhesive side of a strip of gaffer tape:

Then, I fold the tape over, crimp the remaining three sides of exposed tape together, and trim the excess tape from the resulting bundle of Sorbothane to obtain a nice tidy packet which I can place in the case wherever it’s needed.

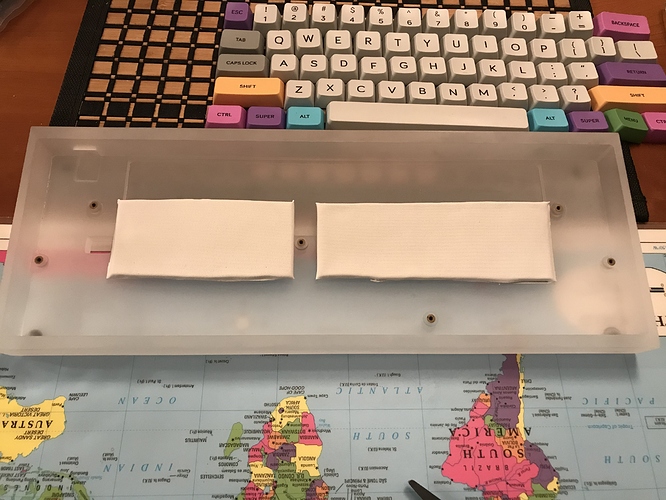

With the acrylic Tofu case, that means I need a couple of layers of Sorbothane packets. The Tofu has a recessed L-shaped cutout area, and hence the case surface is further away from the PCB there. So I started by placing three Sorbothane packets in the center of the L-shaped area:

Then, I placed two larger packets on top of those, to cover the remaining distance to the PCB. Note that there will be nothing other than pressure between the case, the PCB, and each other to hold these packets in place.

Also note that because the exposed surface of these packets is the non-adhesive cloth side of the gaffer tape, there’s no discoloration of the case, and removal of the packets is trivial. Here’s what it looks like from the underside. Just around the edges of the Sorbo packets, you can see a few of the LEDs (the small white squares).

Light from the LEDs makes it to the edge of the case unimpeded, so we’re good to go.

From the top, the case does a pretty good job of light diffusion, better than I was expecting.

And, while this is never going to be a quiet keyboard, the Sorbomummies do a decent job of taking away some of the high-pitched clack. If I focus on riding the tactility and not bottoming out, it’s actually not a bad experience, for such a lightweight board.

Lessons learned

- First keyboard with Holy Panda clones (no, the Ocelot doesn’t quite count), and I like them, but I’m not sure if it will be too much tactility for long typing sessions. The jury is out. Sound is great, though, especially with dampening in place. I need to try a Holy Panda variant in a heavy case.

- Other than having to carefully separate the occasional entangled springs, tub lubing springs works for me. Much faster. Could possibly increase the ratio of lube per spring?

- I finally remembered to get corner switches in and test stabs before soldering! Old dog, meet new trick.

- Gaffer tape + Sorbothane seems to preserve the sound-dampening benefits of Sorbothane, while also making it easier to place in the build, and less potentially destructive (concerns about plasticizers in Sorbothane).

- Gaffer tape also works at least well as silicone pads and/or electrical tape, and I’ll be using it going forward, but in a common refrain for my build logs, I still haven’t found what I’m looking for.

- First experience with MDA caps - the gentle sculpting makes them much more usable than XDA, and the material feels quite nice. With that said, I’d still prefer GMK any day of the week - MDA feels bulky and clumsy to me by comparison. YMMV.

Finally, every teenager that has passed through the house has strongly approved of this board. Draw your own conclusions.

Specifications

case: acrylic Tofu

case dampening:

- 0.188" 30 Duro Sorbothane for bottom layer

- 0.1" 40 Duro Sorbothane for top layer

PCB: DZ60 R2

LEDs: PCB underglow only

plate: DZ60 plate-B aluminum

plate/PCB dampening:

- 0.25" 50 Duro cut to 4mm thick squares

stabilizers: GMK screw-in

stabilizer mods: clipped, lubed, bandaid with gaffer tape

switches: Holy GSUS (Halo True stems)

switch lubing:

- Tribosys 3204 hand-lubed stems & housing (1mL/65 switches)

- Krytox GPL 104 tub-lubed springs (1 drop/7 switches)

keycaps: MDA Big Bone

HxWxD (without caps or feet): 1.25"x11.63"x4.31"

HxWxD (without caps): 1.31"x11.63"x4.31"

HxWxD: 1.75"x11.63"x4.31"

assembled weight: 1.65 lb