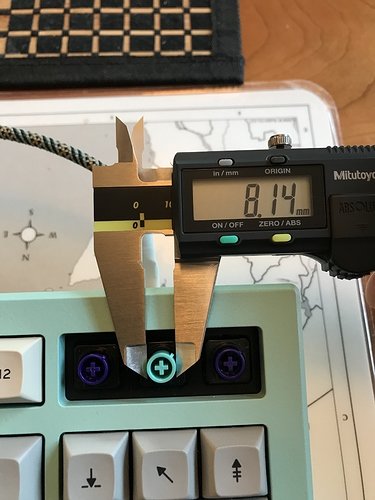

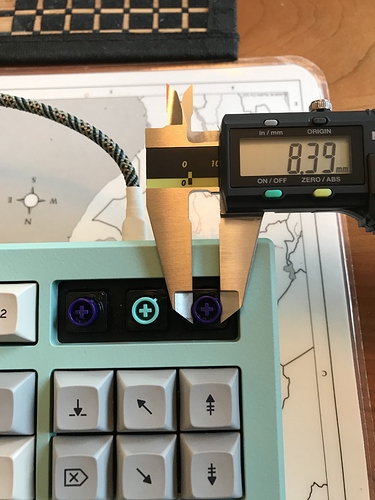

A little hard to show the effect in video, but perhaps these stills give an idea. Looks like approximately 0.3mm more play on the KBDfans slider than the Novatouch sliders flanking it:

After lubing, still different, but I’d say almost all of the difference is wobble; both from the slider stem, and the difference in keycap fit on the stem. In terms of smoothness of slider travel and sound, not a large difference.