Before the first build

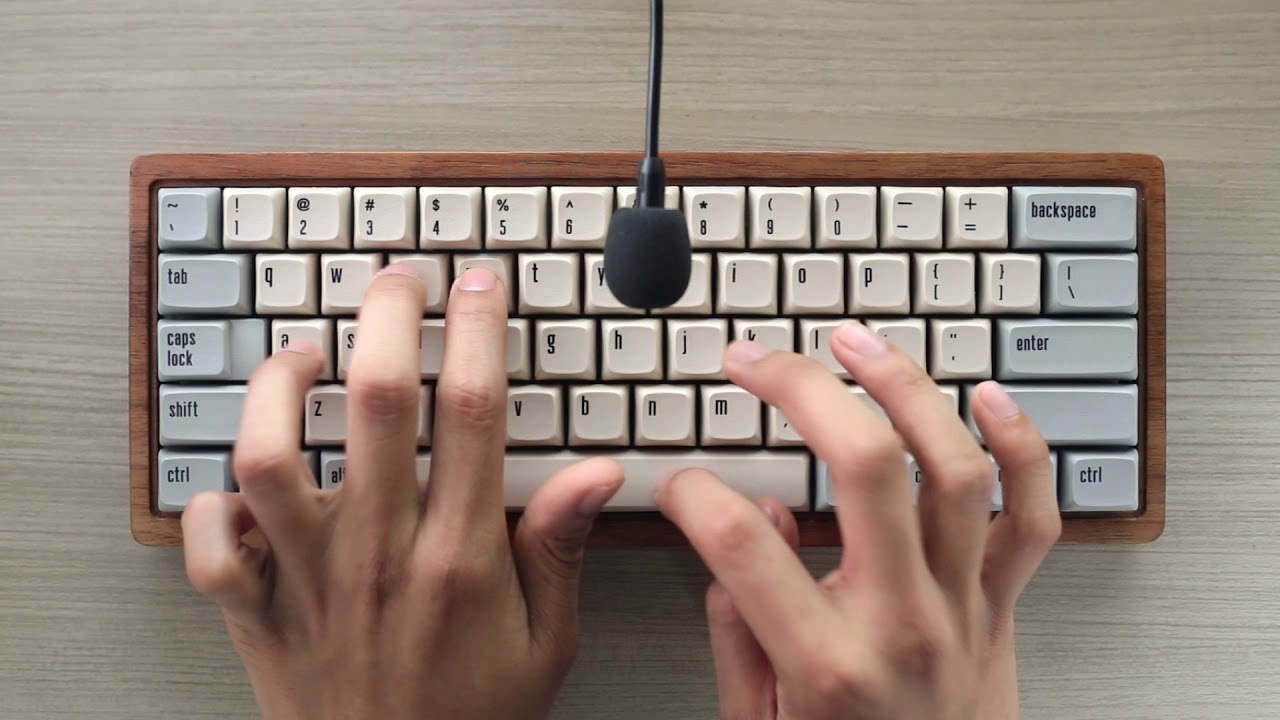

In my introductory post, I mentioned seeing a photo of a friend’s build and becoming sufficiently intrigued to start poking around the web to understand just what I was seeing. The video that really pushed me past the event horizon, though, was this one:

Whoa. I’m not entirely sure what I’m seeing, but whatever it is, I need it in my life. Thus began a couple of days of intense googling and forum catch-up. Sound familiar?

The first order was a Vortex Race 3. I just had to get my hands on a mechanical right away, to try one out, pop off caps, inspect the thing, and just generally get worked up into a frenzy. New hobbies are the best. First impressions: love the heft of this thing, love the reduced footprint on my desk, but not at all sure about those Cherry clears - the tactility is nice, but typing for a while became wearisome. Are all switches this stiff…

The second order? A big-ass switch tester. Need to sort out what this linear/tactile/clicky business is all about. As others have noted, no one can tell you what your preferences are, and no amount of back-and-forth about switch characteristics could ever be an acceptable substitute for trying them out. That didn’t stop me from reading all of the switch descriptions I could find, however, and soon I realized that if I kept this up, I was going to be biased by other people’s opinions, rather than letting my own fingers decide. So, I decided to do blind evaluation when the tester arrived - I would not look at the switches while testing, instead working across the tester by touch while looking away, and making note of the happy sounds and feels as they presented themselves.

And, at least in my case, when the tester arrived and I began my blind test, it was apparent immediately: I’m a tactile guy. And, shortly after working my way through all of the tactile switches, yes, it’s true: Zealios are the way to my feelios. This is as close as I’ve come to a keyboard I experienced in the computer clusters back in college, an IBM board circa 1986 (no, not the Model M), non-clicky, with a similar level of smooth tactile response. That board remains my favorite typing experience ever; unfortunately, I have yet to figure out which model it was, let alone track one down. In any case - Zealios will do just fine.

Time to tool up, but where to begin? I hadn’t soldered anything in a very long time, not since electronics classes in high school, and aside from getting good soldering equipment, it seemed as though people were using several other specific tools and materials for their builds, for purposes that weren’t entirely clear. Fortunately, just I was beginning to become a bit daunted by the prospect of sorting all of this out, Gio’s excellent post appeared:

And not too long after that, a little corner of the garage was reclaimed for its

true calling.

At about this point in the run-up to my first build, one of my sons saw me going full OCD into keyboards, and shortly thereafter became infected with the sickness as well. Cool, now I have a lab partner. We agree it makes sense to get some practice with the tools before using them “in production”, so we picked up a little practice soldering kit and worked through it together.

I’d recommend this to anyone just getting into the game; it’s a great confidence builder to learn (or re-learn) basic soldering technique on a cheap throwaway project before proceeding to a first keyboard build.

Full disclosure - before I begin posting the logs for my builds - the very first build done with these tools was not one of my boards, but my son’s (a KBD75 with 67g Zealios, GMK stabs, and DSA 2049 caps). I largely stayed out of his way, if for no other reason than that I don’t know what I’m doing any more than he does! His build had a couple of rough spots; a bad solder joint which took a little time to track down and fix, and an initially misaligned placement of the acrylic spacer which prevented the USB cable from being able to fully seat in the connector. He worked through these issues with a nice result at the end, which was a huge confidence builder for him, and which made me jealous and quite eager to start my first build! Next up…