Hi there,

as there was some interest in the Hover TKL I decided to open a thread to the Board.

I really don’t like to plug GH in this community but i am running an Interest Check on Geekhack right now for the board and most of the information can be found there. But I also wanted to share my experience on making the board and maybe the thought processes I had or have designing it.

I’ll plug some pictures here and there to make it a bit more enjoyable to read. ![]()

I decided to make my own board about 1.5 to 2 years ago. I missed the GB of the space apollo 80. I was half a year into studying engineering. As i had the tools and knowledge through the school to Design a keyboard i alternatively decided to create my own board. It started first with just something like a training in mind and not the idea to actually build one. Just to increase my skills with the CAD software. That kind of led to designing a PCB with Kicad and out of curiosity if the junk i put together in pixels on my computer would actually work i ordered pcbs from JLCPCB and let the case been milled by instawerk.de. To my surprise everything fit together and worked. The first “proto” was born.

I had so much fun designing, building and experimenting that the idea to give it a shot as a keyboard designer creeped up to my mind. Next i learned how to render with blender and improved the aesthetics with some details. There were so many beautiful boards and still are coming out that i felled the need to improve the design. With the rendered pictures i envisioned the final design. Here is one of my early render a year ago.

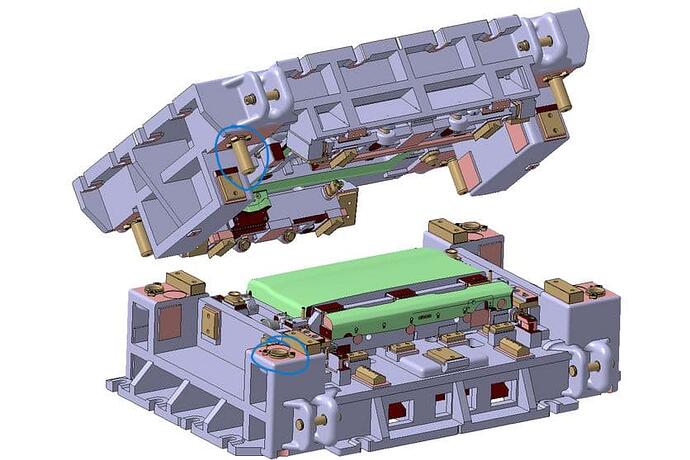

With this design i started to look for manufacturer for the Keyboard and it’s parts. Sadly i had to scrap a lot of ideas i initially had on this keyboard like the really big weight that was able to move up and down to increase the illusion to the hover effect and the gasket system that allowed an adjustable flex of the springs by shifting an o-ring into another postion.

The hardest part for me was finding manufacturers. It really tired me out searching for the right company getting hundreds of quotes. To be honest i probably made my biggest mistakes in that phase due to my inexperience. That is resulting now to high production costs and therefore to a high price.

To the Design idea. What i wanted to achieve was a flat looking board rather than a bulky wedge. By starting off with a flat board like a low-profile keyboard and change the angle to my preferred typing angle i realised the potential of a floating look. By further increasing the effect with LEDs and rounded edges the basic idea was created. Then i took inspirations from the hoverboard of BTTF as this was a close comparison → keyBOARD HOVERing. ![]()

Thank you for reading. If you have any questions feel free to ask.