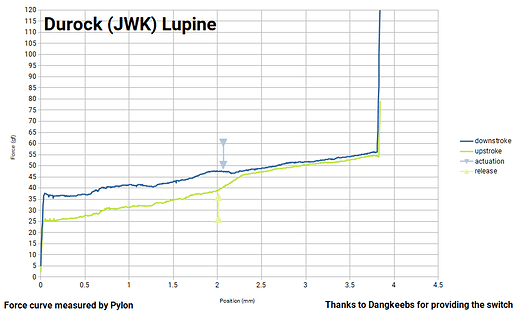

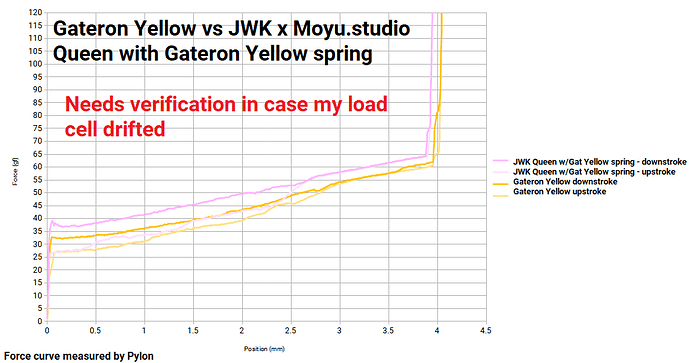

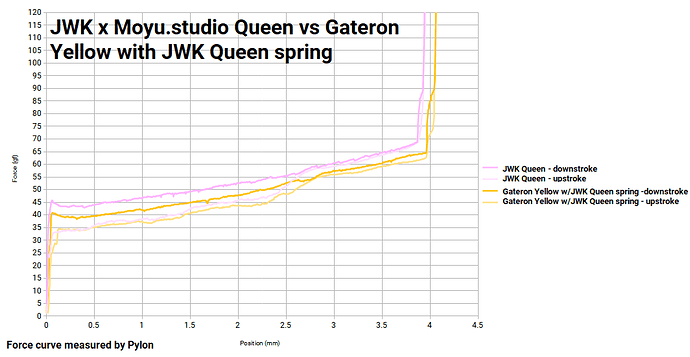

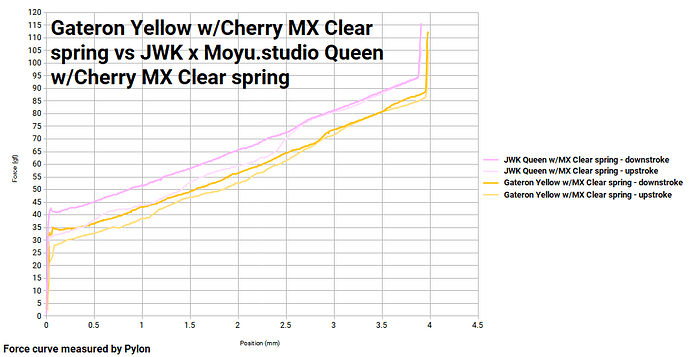

Ok some additional measurements between the two switches with different springs - the JWK x Moyu.studio Queen’s spring (which is a long, “slow” spring), and the spring from a Cherry MX Clear (a short, “fast”, heavy spring)

Both of these measurements show the same result as the earlier one with the Gateron Yellow spring - the JWK stem and housing produces a heavier switch than the Gateron stem and housing when using the same spring. In addition, the difference in force is more pronounced with the Cherry MX Clear spring, which is what’d we expect if the underlying cause is due to a difference in how much the stem/housing compresses the spring - the MX Clear spring has a much higher spring rate than the other two springs, so for a given difference in length it will produce a greater difference in force.

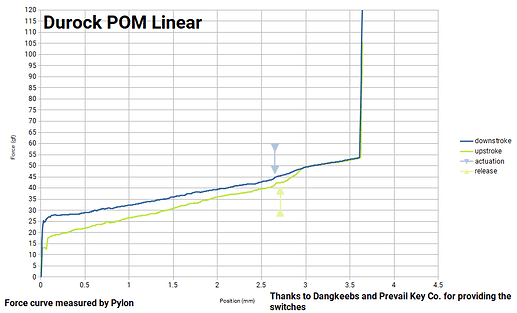

Yes my force curve meter is home-made, and yes its margin of error is probably around few grams. However, error is usually random or non-correlated (i.e. having nothing to do with whether I’m measuring a Gateron or JWK switch - e.g. error due to temperature drift) - if the difference is caused solely by random or non-correlated measurement error, then we would expect on some measurements that the JWK would be heavier than the Gateron. I’m still at a small sample size (currently n=3), but if I can take more measurements with results in the same direction, I would be more confident that this is a real phenomenon rather than a product of measurement error. If the error in force is non-random and/or correlated, and arises to the level of 5-10gf (the difference in my measurements so far), it would likely be showing up on the force curve as noticeable non-linearities when I measure springs, but I so far haven’t seen any non-linearities that large when measuring things I expect to be linear.

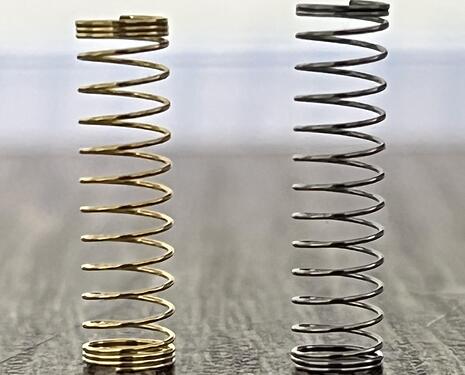

It would be ideal to directly measure the distance between the bottom of the bottom housing and the top of the stem spring cavity to verify the hypothesis. However, this is impossible to measure directly with readily available tools (you can’t just stick calipers inside of a closed switch). You can possibly measure it indirectly by adding and subtracting several more measurable dimensions (e.g. measuring the distance from the stem cavity to the top of the stem, the distance from the top of the stem to the top of the bottom housing, and the distance from the top of the top housing to the area in the bottom housing where the spring rests, and then adding and subtracting appropriately to get the distance between the stem cavity and bottom housing). However, these are still not easy dimensions to measure, and your measurement error goes up significantly when you have to add or subtract several measurements to get the dimension you’re looking for. The easiest way to get this would be to ask JWK and Gateron directly what that dimension is (they can measure this easily in their CAD model), but I’m not sure if they’ll disclose it.

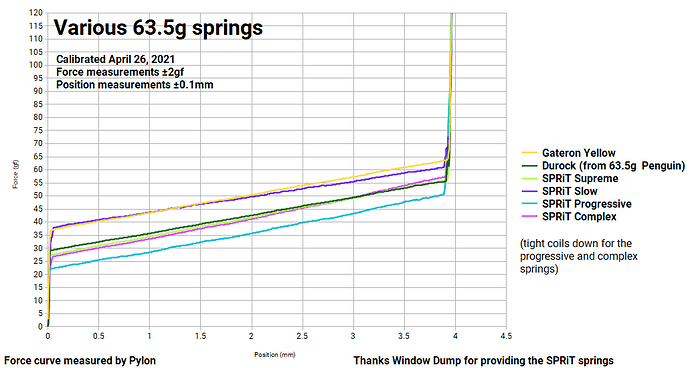

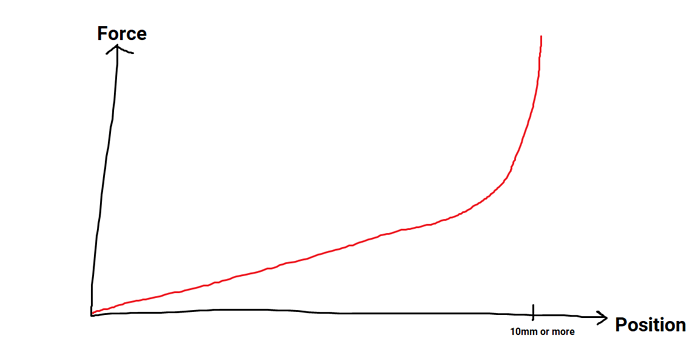

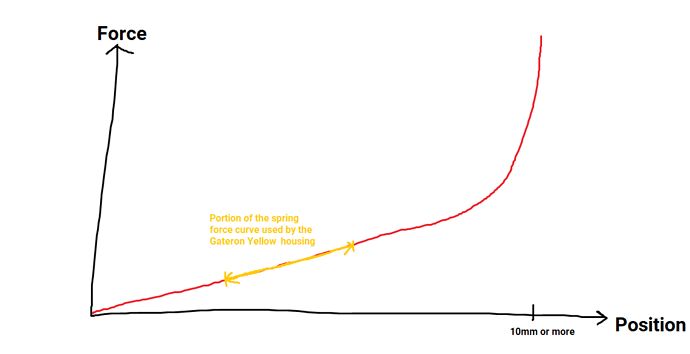

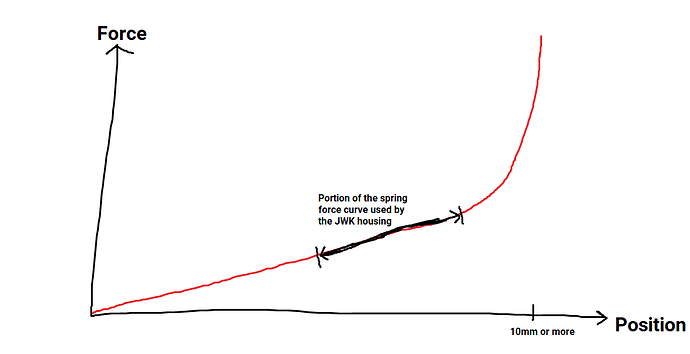

Coil springs are well-studied objects, and force curves of them (outside of keyboards) can be readily found.

Also, I should clarify that in my earlier post I meant to say stem and housing, not just “housing” (my sleepy 2AM brain thought “stem” was included in “housing” and that “housing” merely referred to a switch minus the spring , which is clearly not how it’s usually used)