One could fairly argue that I’m still quite low on the skills curve for designing keyboards, but I thoroughly enjoy my little junkboards and use them almost exclusively. @TheNamesTy45 gives a good overview. I would just emphasize that there’s no one “right” way to do this as long as you end up with a device that you enjoy and feels reliable.

For KiCAD, follow some tutorials and remember that it has twin workflows: first the electrical schematic and then the physical layout. My own PCB was almost laughably primitive, but it worked on the first try and with a slight tweak to route the traces to through holes with a specific MCU in mind (instead of just a line for hand-wiring), it would begin to approach certain (low end) commercial offerings. I will say I didn’t find it particularly intuitive, but just follow step by step and find a “library” of switch footprints and it can come together very well. Fortunately, KiCAD is free and open source and I rarely see newbies directed to anything else. I second JLCPCB (tariffs pending), and they offer a nice discount o your first order.

Of course, hand-wiring is also an option. Joe Scotto has elevated matrix wiring to a kind of art form, but just using old Geekhack techniques, I don’t think I’ve had a single joint come loose in months, and back when I would get the occasional one, they were easy to fix. Just sayin’…

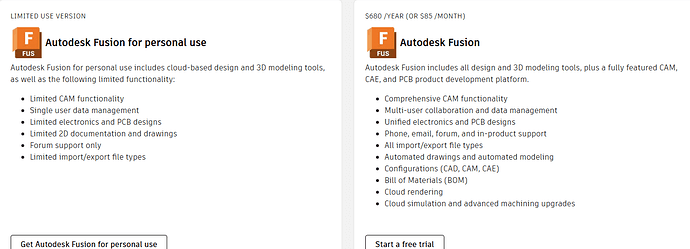

For CAD, Fusion is certainly an option. Autodesk is not the most hobbyist-friendly vendor, and they love to erode features in the free version, but they’re not the worst either, and the number of tutorials is VAST. I actually did a shallow but broad survey of consumer CAD software last year. I personally settled on a license for Alibre Design, but I’m impressed with FreeCAD’s progress of late, and many of the other options are good, especially if you have zero intention of trying to commericalize your work.

I actually did my very first board by designing the plate in TinkerCAD, and you can do some interesting things with it, but tempting as it is, I wouldn’t recommend it. Even something as simple as a fillet or chamfer has to be done as a manual action, and revisions can be a pain if you aren’t very careful in a way you’re likely to have learned by using one of the more sophisticated packages anyway. Sketchup is really poorly suited for CNC and 3D printing, as it doesn’t focus on making geometrically sound models, though they can be mended, that’s just an extra hassle.

With the “proper” Mechanical CAD suites, the important thing to remember is that the core paradigm is “sketch, then extrude (or cut).” They’ll all call it different things, and there are different tools for sweeps and the like, but the basic idea to wrap your head around it is that you do a 2D drawing, then tell the program to “make it this tall.” Then you do another 2D drawing (often on one of the faces of the solid you just generated), and then tell the program to either make that one stick out by X millimenters or to cut into the solid by X millimeters. Those actions stack on top of one another until you get where you need to be. Coming from TinkerCAD, it was hard for me to adjust from “make a block, then stick more blocks onto it.”

I haven’t done a true wooden board (yet), but I don’t think a wooden CNC project would be drastically less expensive than aluminum, though you could save by avoiding finishing processes. The largest portion of the project will still be setup and machine time, and that won’t change much. Wood also behaves drastically differently than aluminum, and I’ve always been suspicious of CNC’ing solid wood. Seems like we’re tempting the gods of wood-movement, and cheap Chinese cases seem to have a reputation for warping. Plywood will behave better, but even with Baltic Birch, you need to be sure you’re up for that specific striated look. I still intend to do an Alps build with a “traditionally jointed” case, which is a fancy way of saying I’m gonna make a glorified picture frame, LOL.

One final point is going to be your plate. Laser or some other CNC machining operation on sheet stock is likely your best option there, and the 3D CAD suites can usually handle that fine, but Illustrator may work too if you’re comfortable with it. I have found strokes are annoying to deal with in Inkscape, so I prefer a 2D CAD option, but I presume an experienced Illustrator user won’t have the same complaints. I had some aluminum plates cut by Xometry, and I found them to be reasonable for 2D work. 3D milling may be a different matter and will certainly be more expensive.

Firmware wise, I’ve been very pleased with KMK, especially with the POG application. I haven’t got my RP2040-based boards working in BIOS before a proper USB stack loads, but that’s my only significant complaint. I do want to dive into QMK though, but while I’m generally tech savvy, my training is in non-technical fields (the law and English literature, LOL).

Overall, though, if you design a working PCB, you’ve got a working keyboard. Keebs have one of the lowest barriers to entry for getting a DIY product that acts and feels like a commercial offering, and the caps go a long way towards making it look like one too. Go for it!!!

![]()