Here’s something I’ve been playing around with for a while now. I’ve shared this abomination with Ryan (@norbauer) and a handful of others but I’ve held off on posting here because I’m not quite sure how I feel about it myself, but here it is anyways.

In my opinion the Heavy Grail is one of the most beautiful examples of keyboard case design there is. It’s strikingly simple yet complicated at the same time. I love the size, the weight, the bezels, the sloped sides, plus I’m a sucker for a wedge shape.

Topre is great, it’s what I use daily. This is not a claim that MX switches are better, they’re just different. I’ve long since sold off my MX boards but I still have a bunch of MX switches and MX keycaps that I wanted to continue using. I wanted my Heavy Grails but with more variety in how I could build and use them. I also hated that I was restricted to a 6u spacebar when GMK base kits all come with 6.25u.

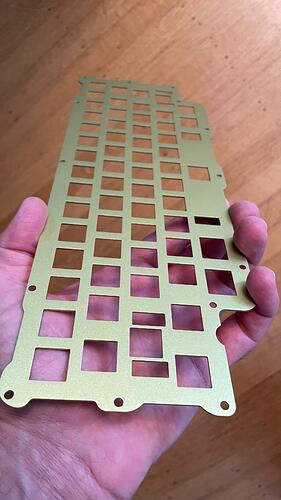

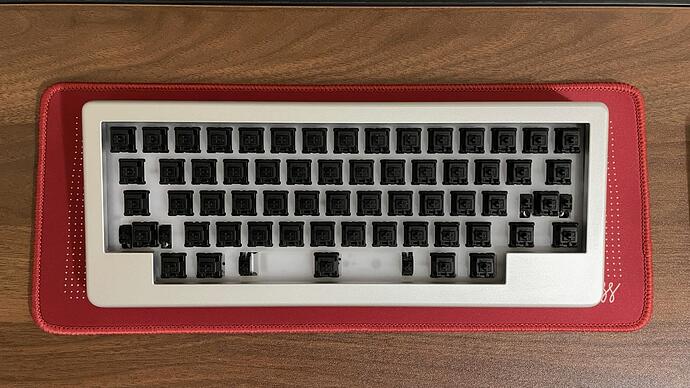

I started with a 3D printed prototype but over the past year or so I’ve gone through a couple iterations of an MX plate that fits into the Heavy Grail case. ANSI, ISO, full backspace, split backspace, 6u and 6.25u bottom row; there’s a couple variants. I have prototypes cut from aluminum and polycarbonate (1.5mm) but my favourite are the ones milled from polycarbonate (3mm and 5mm). Other plates I’d like to try still are 2.5mm polycarbonate (to get a bit more flex) and 1.5mm stainless steel to try change the resonance.

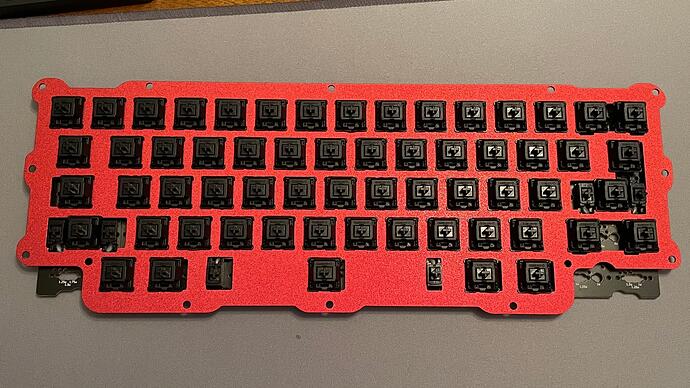

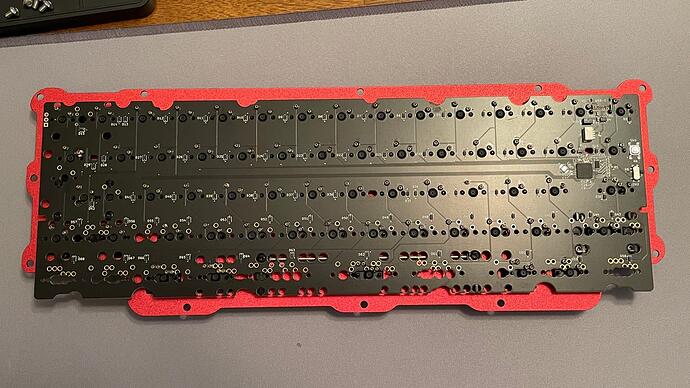

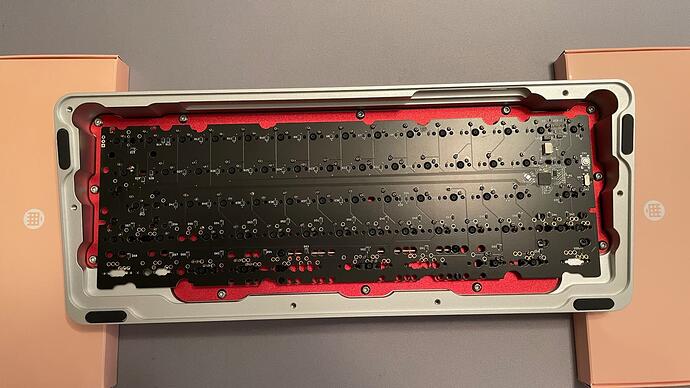

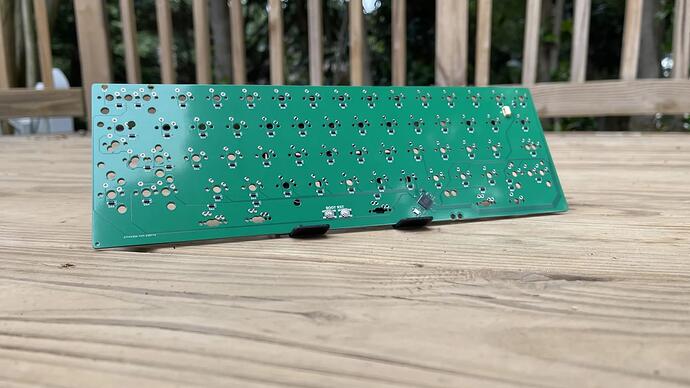

For the PCB I started with the rex60, which could support any layout I wanted to try and the USB cable had to just hang out the back. I’ve since commissioned a custom PCB and daughterboard with support for both hotswap and solder. It’s all nice and neatly packaged in the case now using the standard Norbauer bottom plate. I have a design for a custom bottom plate to try fill up some of the empty space inside, and to fit the standard uDB C3, but haven’t had a prototype of that produced yet.

Anyways, enough talking, here’s some photos.

First 3D printed prototype

USB had to hang out the back early on

1.5mm polycarbonate + aluminum

5mm polycarbonate

3mm polycarbonate

Neat USB now + 6.25u spacebar

Custom hotswap PCB

Custom solder PCB