Hey everyone @dwarflemur (Nick) here. I’ve got a lot of keyboards and I’ve built a bunch of them, so I figured why should we let @jshufelt have all the fun; I’m gonna do some build logs too. At this point I think I’ve put together >10 keyboards, and I don’t really want to count, so I’m just going to call my first log here build N and increment from there. Quick about me before we get started, I’m an electrical engineer in the bay area, I make electronics by day, and play with keyboards by night. Someday I’ll finish my keyboard, expect to see it in like 2021. One thing I gotta note before we get going is I have really terrible lighting at my computer where I do my builds, so my pictures won’t be super accurate as far as color goes.

Okay, so let’s go, Build N: Lubrigante Hamboard.

This lubrigante is from the group buy from @homerow. I actually got two of these bad boys, one for me and one for my girlfriend, but we’re going to start with the first one, which was the red color. I was really into the red, and decided to go all in on the red theme.

So here it is in the packaging. No issues with the packaging, lots of bubble wrap, no chances of damage.

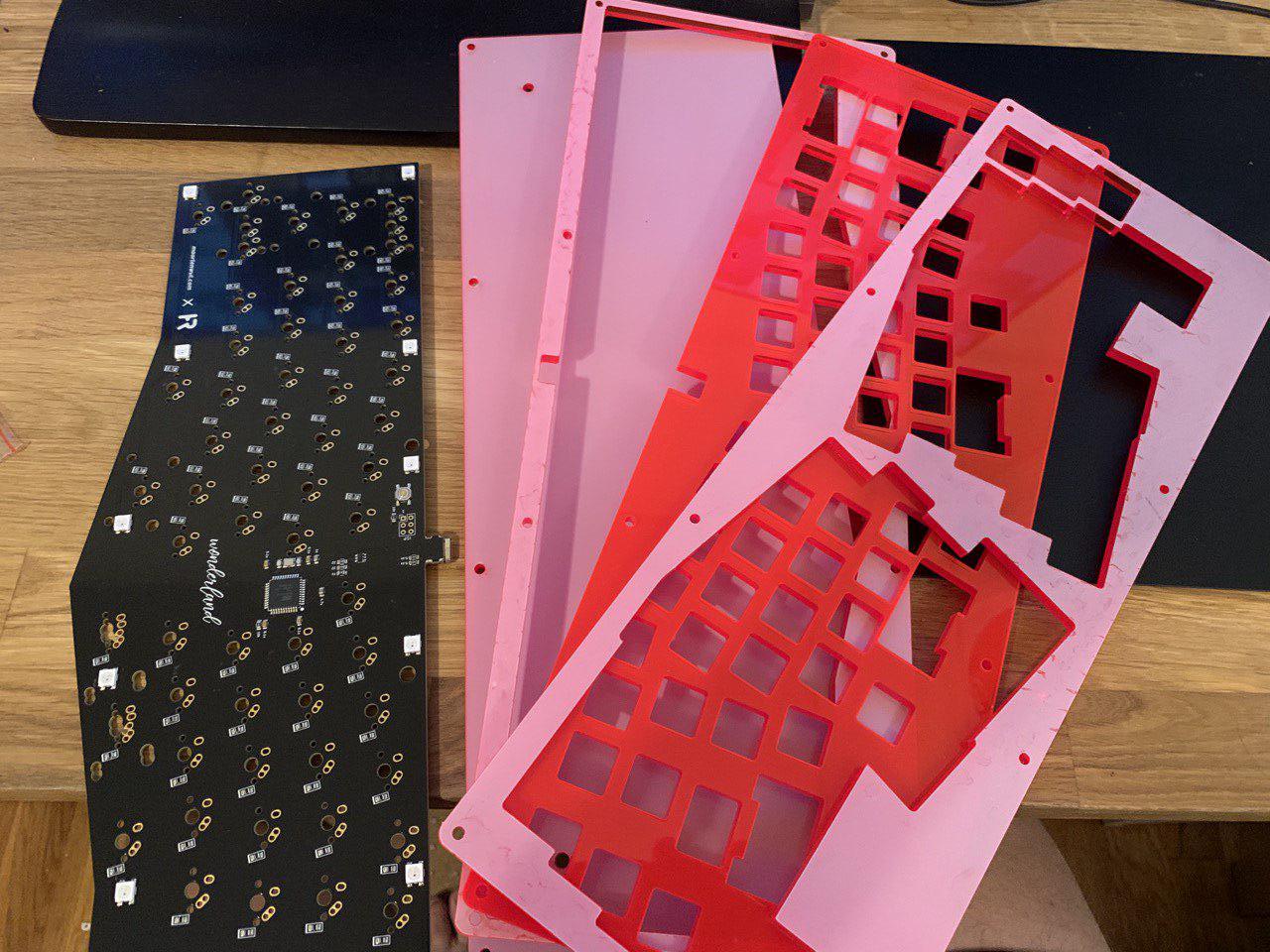

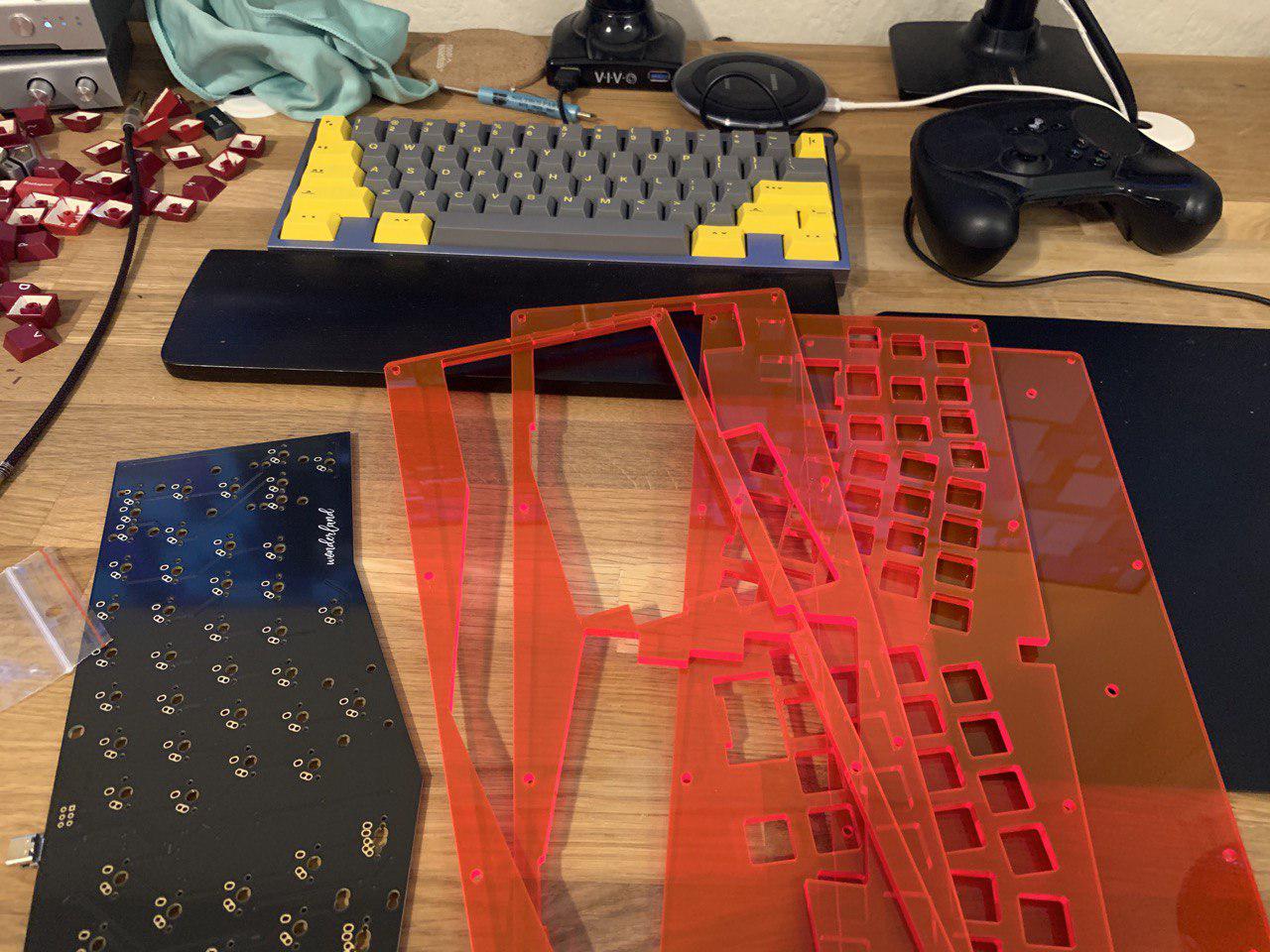

The layers all came with protective film on them (I got excited and took one off before taking a pic). The PCB came in an ESD bag and was also wrapped in bubble wrap.

Everything unpacked and unwrapped. Not pictured: bump on feet and screws and standoffs; we’ll get to those later.

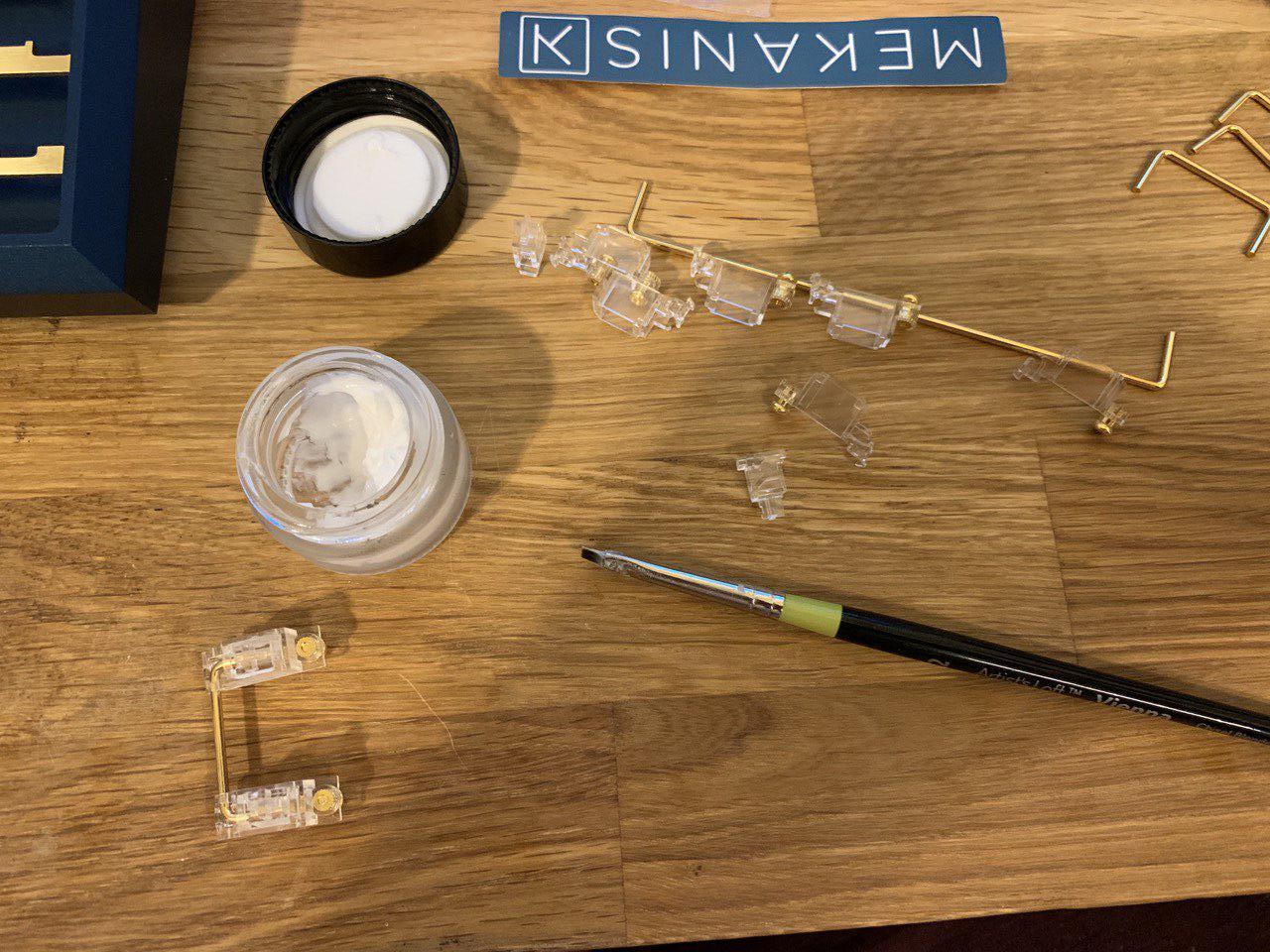

Stabs go first. I like Christo-Lube, so that’s what I put.

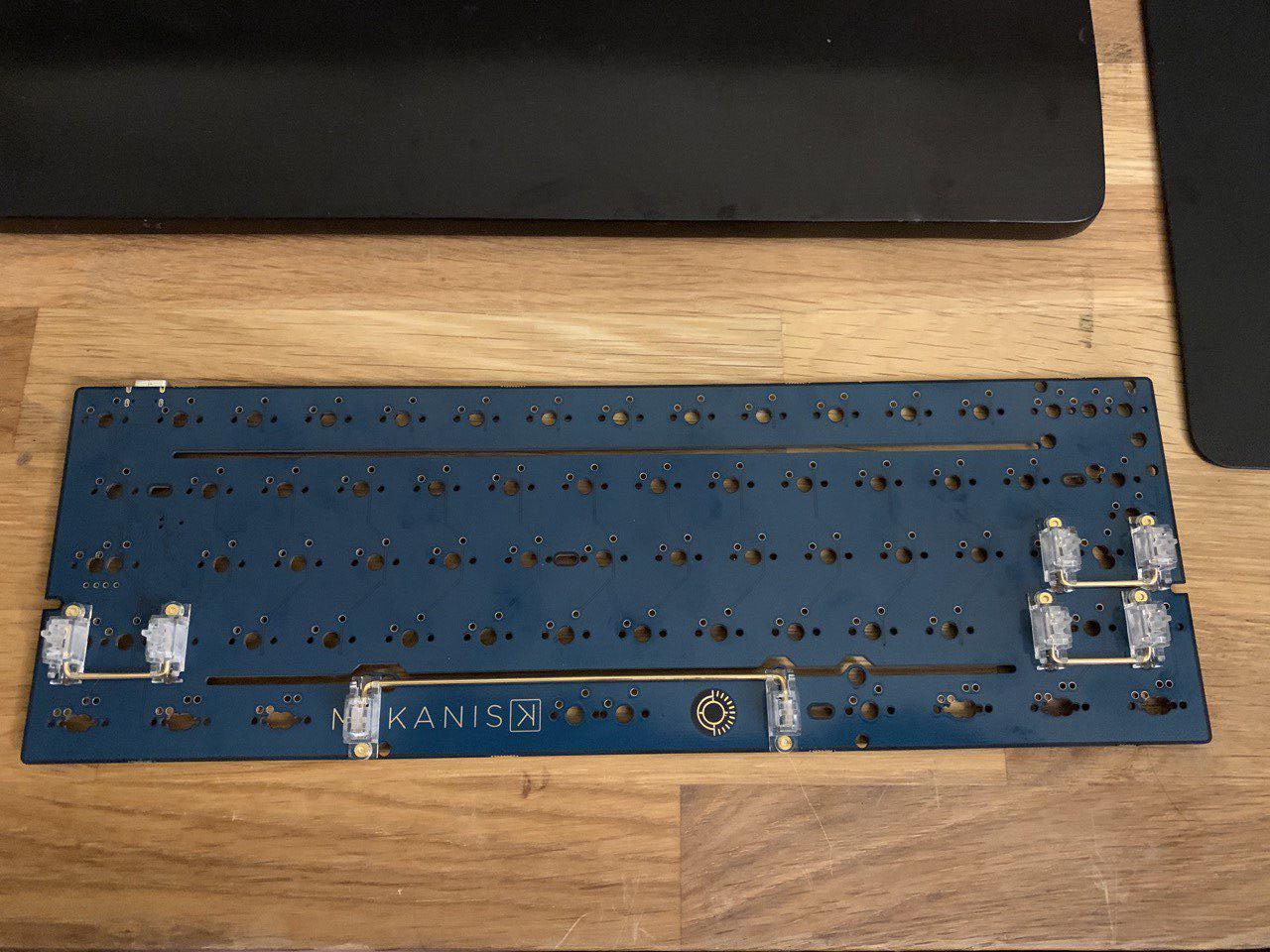

Stabs on the board. It doesn’t support in switch LEDs, so there was no need to worry about the screws shorting anything. Can you see the issue with this pic? We’ll get to it in the next one.

I primarily use right shift, and I like a full size one. I was planning to use the bottom right key as FN here. As it turns out, even though the PCB supports a full size right shift, the plate for this one does not. Oh well, we’ll just put FN there then. It’s always a good thing to check before putting in switches.

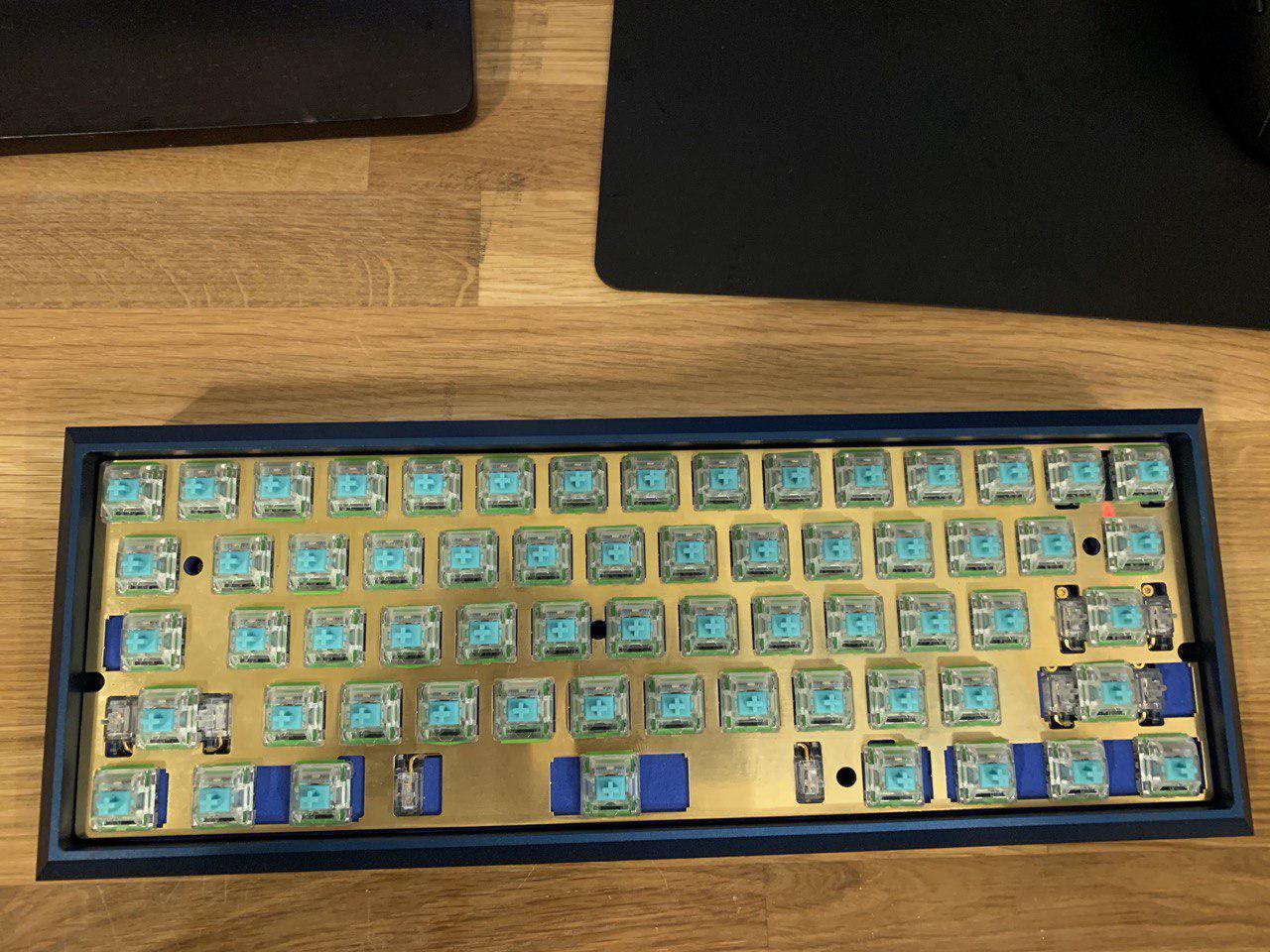

The switches. Of course I had to go with red inks to match the red keyboard. I was planning on lubing the switches, but in the end I decided not to after seeing some talk around about issues with the leaves when lubing inks. They seem plenty fine without for my taste.

Switches going in. There are a few things going on here. The plate is a thick plate, so there is almost no space between the plate and the PCB, but there are no cutouts on the bottom of the plate for the switches to click in. Besides that, the holes in the PCB for the switch posts were pretty tight, so I had to make sure to push the switches in all the way to get them both into the plate and PCB. We’ll get back to this later.

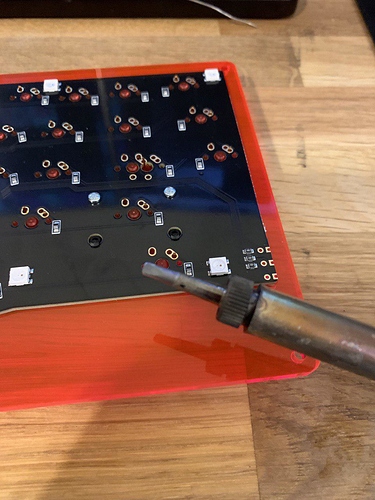

All the switches in, time to solder.

My go to soldering iron. We have a nice soldering station with fine tips and a microscope at work that I can use if I need to, so I use this one at home. It’s a Weller that plugs into the wall with no temperature control, but oh boy is that giant chisel tip awesome.

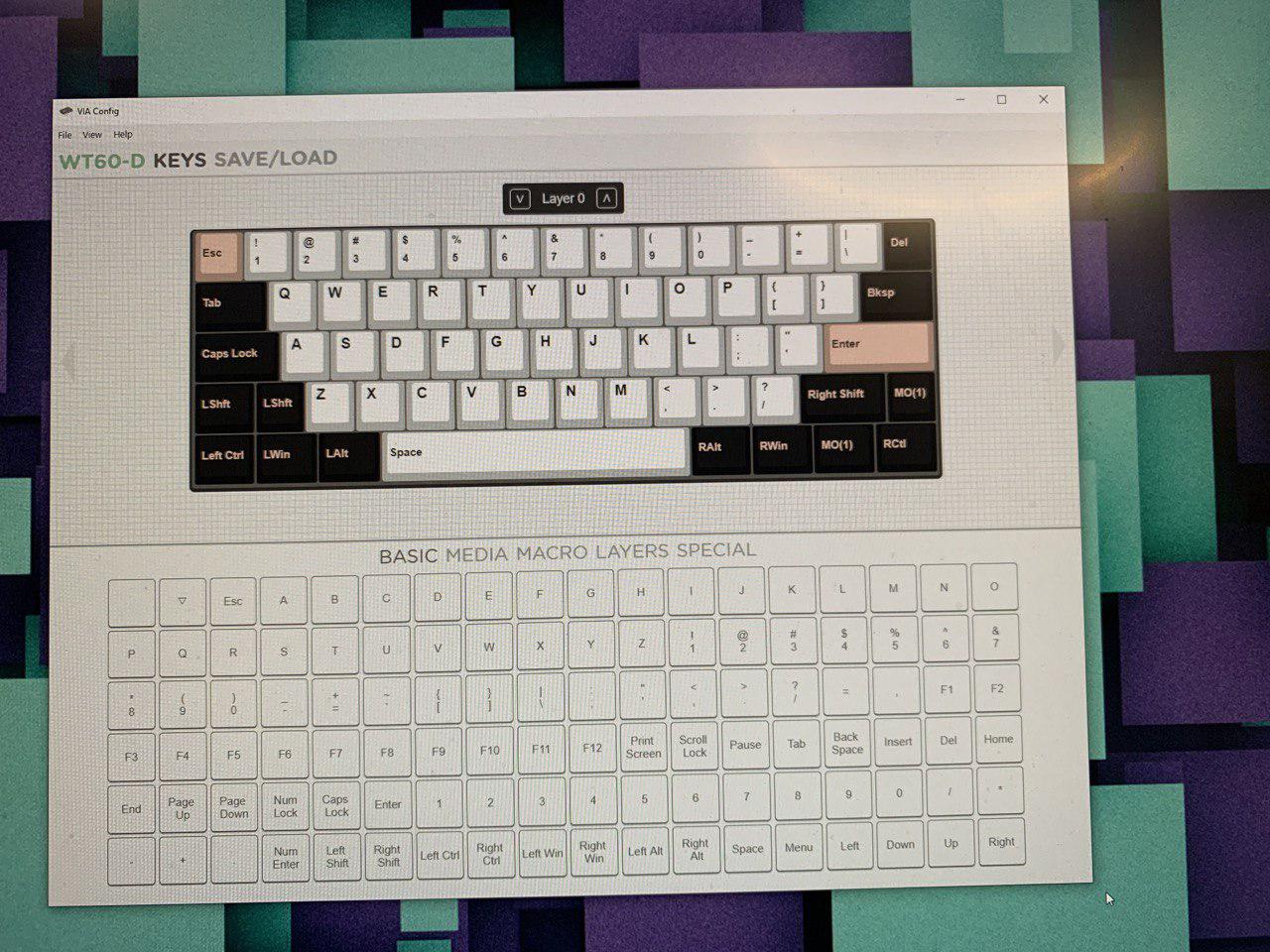

Post soldering. I plugged it in to make sure everything was working, and found out I forgot to solder one of the B keys. This was also where programmed it, before I put it together in case I needed to push the reset button or something, and so I could make sure everything was working as expected.

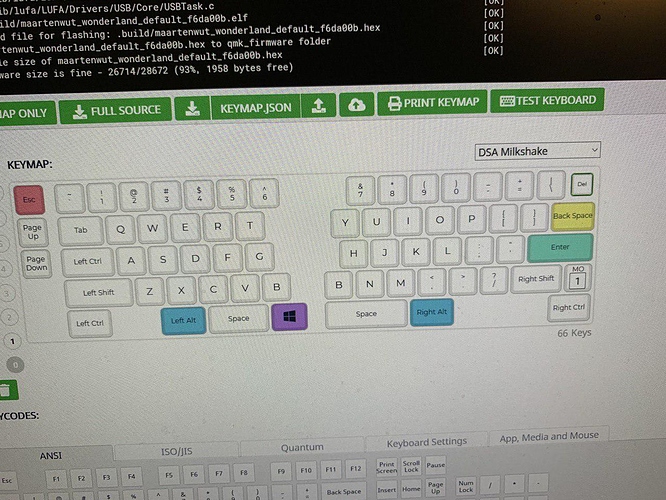

My programming. Nothing wild, HHKB arrows, F keys, and LED control on the FN layer.I might switch windows and left alt so I can alt tab without really needing to move my right hand, need to spend some time with it to see what I like better.

Time to put it together. Screws and standoffs. It also came with some LEDs presumably for caps lock, etc. There is a cutout in the second layer for the LEDs in the bottom left of the keyboard. I decided not to populate them.

The end product with keycaps. I was deciding between Jamón and Red Riot to go on here, but in the end I decided I like the reds better on Jamón, and besides, I got the 40’s kit with the extra ‘B’ key, so I might as well put it to use. I found that once I put the keycaps on the right spacebar didn’t come back up when I pushed on it. It turns out, I hadn’t pushed the key into the plate all the way, and so it was soldered a little bit tilted, which caused friction with the stabilizers. I was able to heat the solder up and push the switch into place, but it’s still a little bit slow on the upstroke. Nothing that bothers me, but at some point I’ll probably de-solder it and do it right.

Thoughts on the keyboard:

- The plastic (acrylic?) was very well cut. No burn marks or scratches or anything on it

- I with the plate had cutouts for the switches to snap into. I had to be careful to make sure they were in all the way, and I still had a key with issues. I bet if I went through the alphas they aren’t all perfect.

- This is my first Alice-like keyboard, and the extent of the typing I have done is this write-up. So far I like it, it doesn’t seem like I’ll need much adjustment to get used to it. I have pretty big hands, and my right thumb kinds seems to sit naturally on the gap between the left spacebar and the key to the right of it. I can probably get used to it. I primarily hit space with my right thumb when I’m typing, so not a huge issue for me.

- I think there were options for a black or white PCB, I think white might have looked better. Not a huge issue for me. The black matches the screws.

- I’m generally not a huge fan of sandwich cases (although my first “custom” was a sandwich clueboard with round 2 zealios way back when. I don’t have that keyboard anymore but I kind of wish I do. I have fond memories of it). The layers on this one match up pretty well, and the red with red underglow looks awesome.

- This is my first build with the red inks, I like them a lot. I have a board with silent inks that I use at work, I don’t think these are as awesome as those, but I enjoy typing on them.

- The sound is solid, maybe I should figure out a consistent recording and I can put some audio to go with these in the future.

- I wish it supported full size right shift. Not a huge issue. I probably could have cut a hole in the plate if I really wanted it.

I’ll probably take this board into work, and provided the sound doesn’t bother my co-workers too much (I work in an open office) keep it there for a while. It’s gonna look great with my baguette wrist wrest. Overall I’m very happy with it.

Full specs:

Lubrigante Hamboard

- Homerow Co Lubrigante in red

- Gateron Red Ink switches, unlubed

- GMK screw in stabs, lubed with Christo-Lube

- GMK Jamón