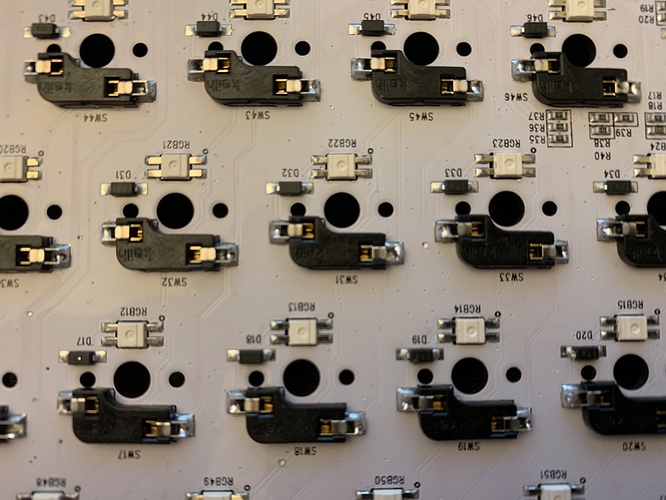

Amount of solder on Kailh sockets varies between boards. On KBD6X board I have, the area above the part touching the pads are practically filled with solder. In comparison, Planck rev6 PCB appears to have solder only on the padding, not unlike KBD6X RGB and 1upkeyboards’ HTE60 PCBs I have which I had to add extra solder to secure the sockets.

UPDATE: Here is one of the PCBs I resolder to secure the socket.