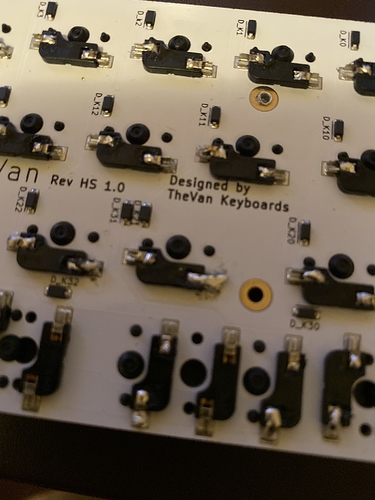

This is something I’ve been curious about ever since getting the kailh sockets in hand and putting them on a pcb. If you look at the back side you can see the pins of the switches poking between the compression contacts in the socket. It should be possible to solder the switch into the socket for permanent installation.

Why might someone want to do this? The kailh sockets are rated for 100 changes. I was stress testing them and got bored at 20 changes. While 100 changes will probably be sufficient for most, I can imagine a scenario where the sockets wear out and leave the pcb pretty much worthless.

Another scenario may be that you have found your perfect switch and a non hotswap version doesn’t exist. Every time you swap caps you inherently end up pulling some switches out.

Whatever the reason, is it even possible?

Turns out it is totally possible. I’m writing this post on the board from the above pictures. Getting the solder to flow down into the pin contact area is a little challenging. A very fine tip would make it easier but this is still quite a bit more time consuming than a normal solder pcb. It’s very easy to overload with solder.

Here’s a video showing the switches much more secure to the pcb.

Would I do this again? Not if I can avoid it. It’s time consuming and a bit challenging. This would be a great fix to a loose socket thought (provided you don’t want to change switches anymore).