Warped spacebars. Nobody likes them.

At worst they’re unusable, and at best they make stabs much harder to tune. There are various methods of straightening them; particularly with PBT bars which themselves probably compose the lion’s share of warpage - but none of those methods seem particularly… controlled… to me.

What’s more, many of them don’t work on or may damage ABS.

So, what do for someone like me, who wants a reliable way to straighten bars with no practice? Here’s my thought - this might be a big dumb, or it could possibly lead to a good thing - so I’d love some feedback about it:

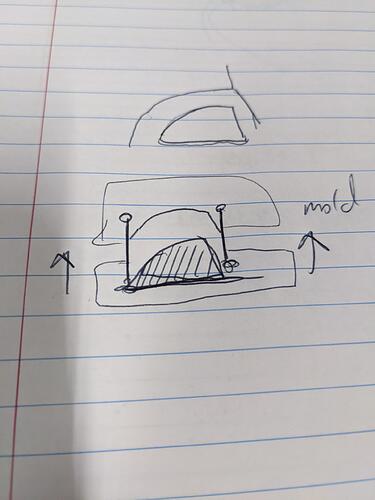

I’m envisioning a machined jig with MX-style mounts in common spacebar positions - a hard metal thing to mount the spacebar on that will essentially hold it in the correct shape while heat is applied.

I could also see having some kind of straps or integrated weight thing to help with flatness as well, but my primary focus here is on straightening and lining-up out-of-spec spacebar stems.

Beyond that, I’m envisioning some kind of controlled heat application - and after some light research, I’m thinking water immersion is the way to go. At first I was thinking heat the jig itself, some other piece over it, maybe even a press-with-blanket type thing - but just immersing the whole thing in water at the right temperature seems a lot more simple. Maybe it could ship with a thermometer and a little chart of temperatures for different plastics.

The idea is to apply only as much heat is needed while the spacebar is being held to the desired shape - not just flat, but with the mounts all straight-up-and-down. The idea is also to de-couple the straightening process from skill as much as possible - I want this to be easy, approachable, and un-intimidating.

I love my ABS MT3, but about half my spacebars have just enough warp to make them into stab-nemeses. Totally gorgeous, excellent-feeling cap sets sounding worse than they should on my otherwise reasonably-tuned test keeb… surely there’s a better way. That’s what got me thinking; if only I had something to hold the stems in the right position while I apply a little heat…

So - more trouble than its worth, or might I be barking up a fruitful tree here? (Or has someone already done all of this barking and/or harvesting?)

drop.

drop.