I wonder if the adhesives for either method would deteriorate over time, given the constant mechanical contact with the wire and the lube applied to it. If went to all that trouble for the glue to fail, I’d be pissed, lol.

I’m also worried about the longevity of this mod, and also how it affects the snappiness of the stabilizer response. Its best to just spend some time balancing the stabilizer wires and also add a bit of heatshrink on them.

Holee mod is totally doable in C3 stabs but you just have to make the bandaid shorter so that it will only cover the angled part and not the flat part where the wire enters, if that makes any sense? So technically it’s like epsi mod but you only apply the top part but with bandaid instead. Honestly it’s one of the best stabs I’ve done so far, much easier to tune than Durock V2. I’d upload the video but I can’t seem to post links here lol.

Edit: I can post a video now lol

https://www.youtube.com/watch?v=X3X7abr3REo

You might need a few more posts to be aloowed links as you just joined a few hours ago.

Might be some internal Spamprotection

yeah makes sense. either way it feels super clean on c3 with half(?) holee mod. no mushiness at all and i havent relubed or plugged the butt once since the first time.

Yea thats why I want to try it. I somehow always have troubles with the Stabs and this while its just as work intensive would make it more consistant.

I tried out the holee mod on my Enter key stabilizer. Recorded a video showing the difference against the backspace key stabilizer without the holee mod: Sound test video

From my observations, there’s not much difference to the sound, rattle or stability of the key. As for the key feel, the holee mod makes the stabilizer a little more “cushioned”, while not really giving a dampening effect. Overall, I think it’s a harmless mod but doesn’t do too much as compared to clipping, lubing and balancing stabilizer wires

Build:

- Everglide Panda stabilizers, lubed with dielectric grease

- Boba U4 62g switch, spring lubed with 105

- Varmilo white and mint keycaps (Cherry profile dye sub PBT)

- GK61 with alu case and alu plate

Update:

After using it for a day, I decided to remove the mod. Reason being, the stabilizer felt too sluggish for me. It felt worse than having o-rings under the keycap - since stabilizers don’t have springs unlike switches, there’s nothing that counteracts the sluggishness

I liked the crisp snap that my other modifier keys had, this one Enter key felt “off”. If I were to describe it, it would be like groping into a bag without looking, and your fingers touch something moist and mushy.

Removing the mod was an unpleasant experience. The bandaid piece that was placed into the stabilizer holes wears out easily. While I was pulling it out with a pair of tweezers, the bandaid was disintegrating. It made things annoying and a little more messy.

Of course, YMMV but in my experience, I would avoid this mod altogether

Hi all. My first post here.

So I’m someone who likes 55g - 58g spring weights, and so lots of lube in stabs is a problem as they start to stick. I also hate having to relube my stabs. I haven’t tried the holee mod (with a band aid) for fear it would simply clog up or break down. I thought the Rama heat shrink mod had the most promise, but I couldn’t get it to work because a wire with heat shrink wouldn’t even fit in the stab stem hole. So a simple solution was born (I’ve done this on three boards so far and it works well):

-

Using a very small handheld rotary drill bit, I manually increase the hole in the stab stem. I remove enough to ensure that the stab wire operates as it would normally without heat shrink (e.g., laying flat when a key is depressed). I also clean out the shaving debris with a tweezer and compressed air and / or a vacuum.

-

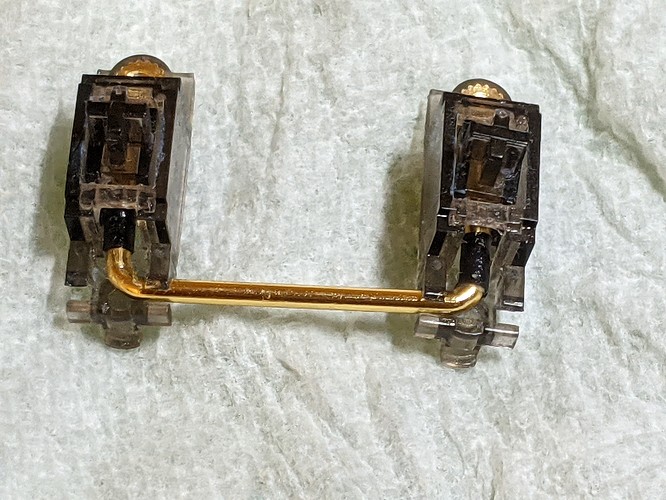

I place 3/64" heat shrink on the stab ends. Depending on the stab, I can often use the heat shrink all the way down to the bend of the wire without it binding. To help ensure it stays on, I first rough up the end of the wire with sand paper. I then put a bit of thin ca glue on the wire before sliding the heat shrink on. Because CA doesn’t bond well with polyolefin, I prime the polyolefin first. And I also let the heat shrink wrap the end of the wire. To ensure the heat shrink wraps around the end of the wire, just make sure to put on more heat shrink than you need (have it stick out past the wire end). Heat it up, it’ll wrap the end, and then just cut off the excess with small scissors. The heat shrink should go no where.

-

I also sometimes shave a tiny bit off of the stab housing (the little bar) where the wire will hit when a key is in the up position. I use a micro file to do it.

-

I then use Krytox 205g0 on (a) the inside of the housing and outside of the stem, very light coat, as usual; (b) some on the wire bend, as usual, but not a lot; and © a very light coat on the wire end that is covered in heat shrink.

Anyhow, I’ve done the above with Durock v2 screw-in stabs, NK plate mount stabs, and Everglide plate mount stabs, if I remember correctly. Worked for all of them, except that I had to make the heat shrink a bit shorter on the NK stabs so that it wasn’t as close to the bend in the wire. In the Durocks I could basically take the heat shrink all the way down to the wire bend. You always want to check your plate too, as I found in one of my boards, the Stellar65, that I had to shave back some of the plate a bit to help accommodate the slightly thicker wire with the heat shrink (but that was because I use the heat shrink all the way down to the wire bend). And best to test the heat shrink mod first on the board without gluing the heat shrink. Once you know it works, with no binding of the stabs, then you can redo the heatshrink with thin CA glue.

Cool thing about this is that the entire wire inside the stab stem/housing is heat shrink. No more rattle. And it also doesn’t need lots of heavy lube. I’ll try to put a more detailed tutorial together, in a separate post, and maybe a video. I’d love it if other people tried this mod too, especially people who spam their keys!

If it turns out this is the best approach, then it would be great for vendors to sell stab stems that have holes that are already big enough for 3/64" heatshrinked wires.

In conjunction with the above, I use the Upgrade Keyboards stab pads under the stabs.

Ultimately, the stabs are super responsive, even with very light weight springs, and the sound is great. Not mushy at all.

Best,

LexProf

Idk i kinda like it but also don’t, it helps with cheap stabilizers and ticking. Though i’ve found that just balancing the wires is good enough, especially since the holee mod affects the sound in a negative way for me.

Interesting, the opinions seem to diverge. Andy has tested all mods in a stream of several hours and found the holee mod best and will probably use it in the future.

Since Andy also makes commission and has a lot of experience, I assume that the holee mod is useful for him and better than DG or xht-bdz.

My concerns are with the longevity not the mod, not the immediate feel. I’ve heard multiple accounts of the material used in the mod shredding and dislodging in time. Grease can easily be reapplied. I just did a set of stabs with BDZ (on a hotswap board for testing), so I’ll have to see if it lasts at all.

Same here, it’s the longevity that worries me with these mods not the initial performance. Also I’m in the camp of people who never really had many issues with clipped & lubed stabs. XHT-BDZ definitely seems to be holding up a good bit better than dielectric grease, super lube, 205g0, or 205g2 IME so I’ve been leaning towards that being my solution to lengthen the amount time between having to refresh stabs. So far my Devastating TKL would be the build that I’ve used stabs tuned with XHT-BDZ the longest on (about 4 months now) & honestly they feel just as good if not a bit better than the day I lubed them! I’d recommend giving some XHT-BDZ a try before any of these material mods myself.

Good to know that the BDZ is holding up. Honestly I’m not sure how I could refresh a build with it though unless I desoldered the board. I wonder if when the time comes, I could syringe in some dielectric over top of it? Fingers crossed that it just stays in place until the apocalypse.

You could easily just use a brush to jam more into the slider it seems, also I’ve heard that BDZ & 205g0 play well together so it should be possible to refresh with that. Although I have just heard 205g0 plays well with BDZ, I have yet to try it myself so I can’t say that is possible for sure.

depends on which holee mod your using, I’ve put cotton and tape, taht fell apart in 1 day. Then there is jsut bandaid, that worked amazing for both sound and time (used for like 15 days before trying the other mods, held up as if there was no lube there). And then there is just too thin(waterproof bandaids) or too thick bandaids, too thin = barely any difference and too thick = feels like it’s overlubed but it won’t settle in.

I can recommend buying some syringes for relubing, just fill it up with lube, lift up the stab so you can see where you want to apply lube and squeeze.

it makes it pretty easy and quick

did someone tried the holee mod with zeal stabs (less tolerance)?

I’m gonna revive this thread because I really didn’t want to create another whole thread just for this.

The Holee mod to me is slightly mushy and muted and kinda going for that clean, I mean Mr. Clean-uses-it-in-an-ad Clean kinda spacebar.

So is the Epsi a bit more snappy from the holee? (Woo, I’m talking keeb-glish!) Doesn’t seem that hard to do and I’m fine taking days to get a better result.

Edit: Aww geez I necroed a 4 month old thread lol

I’d follow this to see what @ajoflo learns from the dry-stab mod. Seems like it would be something Mr. Clean would use.

Trying to drill the holes manually, but I gave up. I will try to buy an electric drill to try later with my GOAT stabs.