First, I’ll get the important questions out of the way for mechanical keyboard enthusiasts who are familiar with Beam Spring switches.

Specs

- Beam Spring click mechanism

- Hall Effect sensing (Over a billion press lifespan)

- Cherry MX-mount stems (engineered to be safe for all keycap brands)

- Plate — 14mm x 14mm square cutout

- SMD LED support (Dual LED support possible)

- Dust Resistant Housing

- Contactless PCB Mounting

Unfortunately, Silo switches are not compatible with Cherry MX-style PCBs. I’ll explain more below — hopefully the innovation of contactless sensing makes up for having to buy a new keyboard.

What is a Beam Spring Switch?

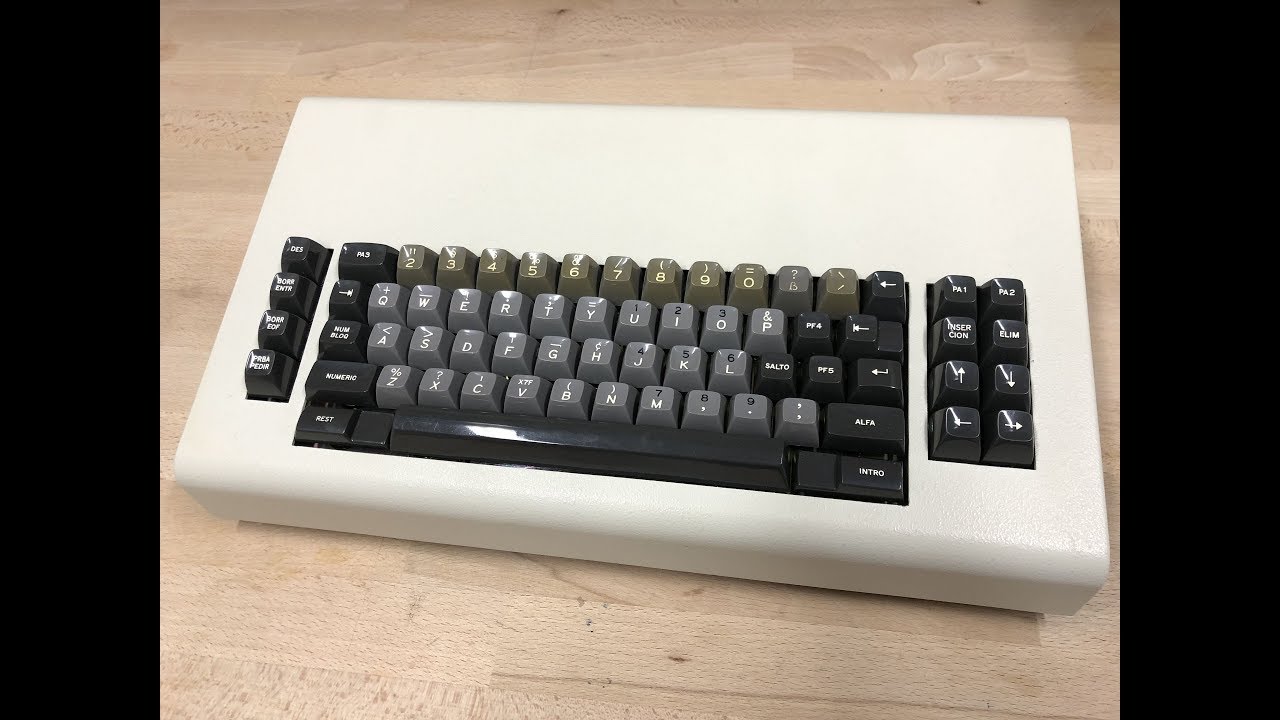

Way back in the early 1970s, IBM needed a more configurable replacement for the Selectric keyboard. At the time, Selectrics were often used as “mechanical” keyboards for some computers and terminals:

Datel 30 Terminal

Using a Selectric as a keyboard is rather cumbersome compared to discrete switches, but what about that “Selectric Feel”? This is rather difficult as the Selectric uses an active mechanism known as a whiffletree (File:IBM Selectric II typewriter.ogv - Wikipedia) to achieve its legendary tactility. It’s also the reason that Selectric keys don’t work at all unless the typewriter is powered on.

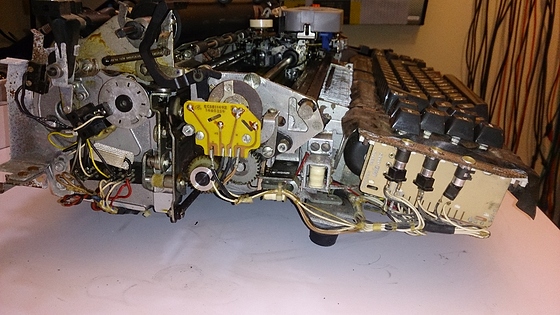

(Inside of an IBM Mag Card II)

IBM’s solution was the Beam Spring switch (Beam spring - Deskthority wiki).

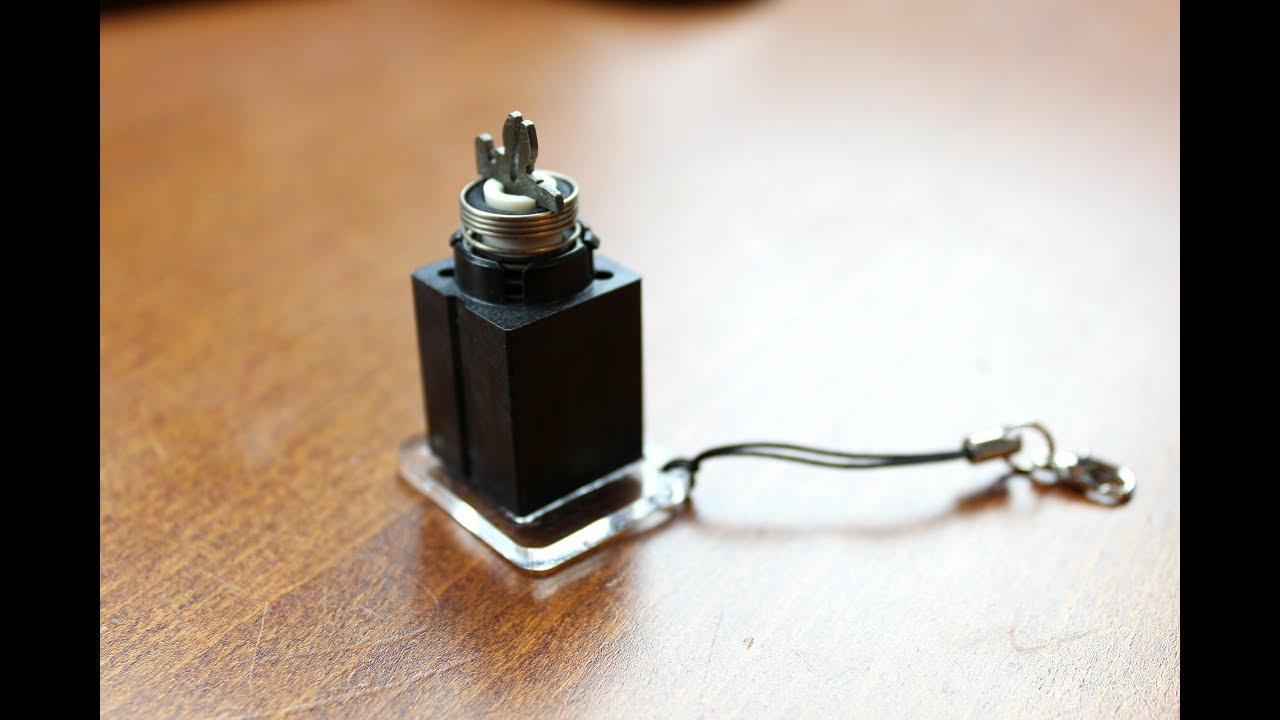

(Credit bhtooefr)

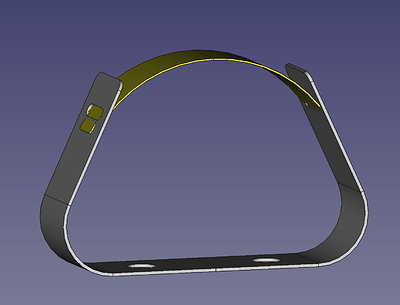

A beam spring is a strip of sheet metal held under tension at two ends, forming a slight bow. When exerting force downwards into the bow, the beam will push out the tension points on either side until there is enough tension force to buckle the beam in the other direction. This buckle is what creates that pleasant tactile feel and sharp audible feedback. On the rebound, a coil spring resets the beam spring to its unbuckled condition.

Really though, you should just watch ChryrosRan22 give a proper explanation of the process:

Why a Beam Spring Switch?

Beam Spring keyboards have always held a special status within the keyboard community. Their remarkable clicks, retro aesthetics, amazingly thick keycaps, and build quality (costing thousands of dollars when new) are a throwback to an era before planned obsolescence. Extreme rarity and incompatibility with modern computers, unless extensive DIY restoration mods are performed, makes owning an original a point of pride for collectors. Most importantly, Beam Spring keyboards are near-universally praised for their feel. This is mostly due to their Selectric-inspired performance, offering an experience unlike any other switch mechanism.

But why do Beam Spring switches feel so amazing?

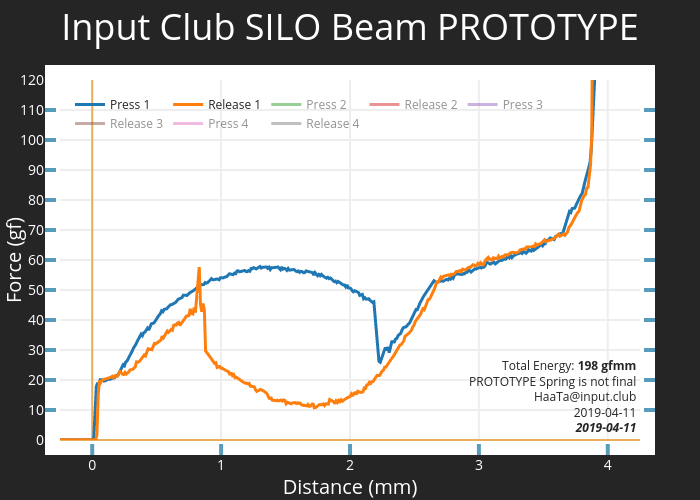

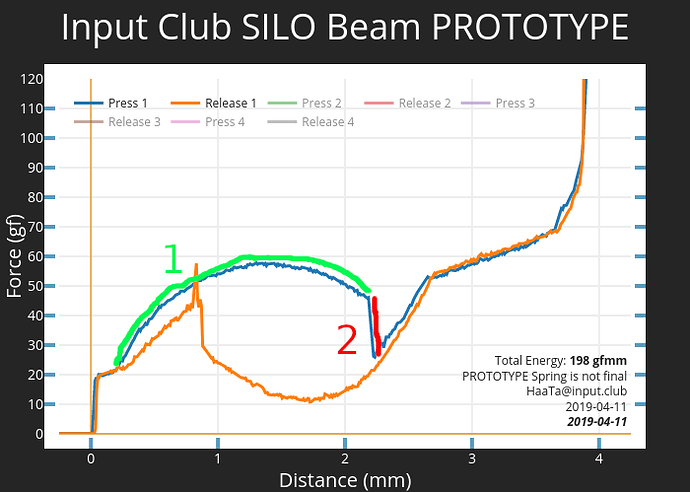

https://plot.ly/~haata/638/input-club-silo-beam-prototype/

(Silo Beam Prototype Force Curve)

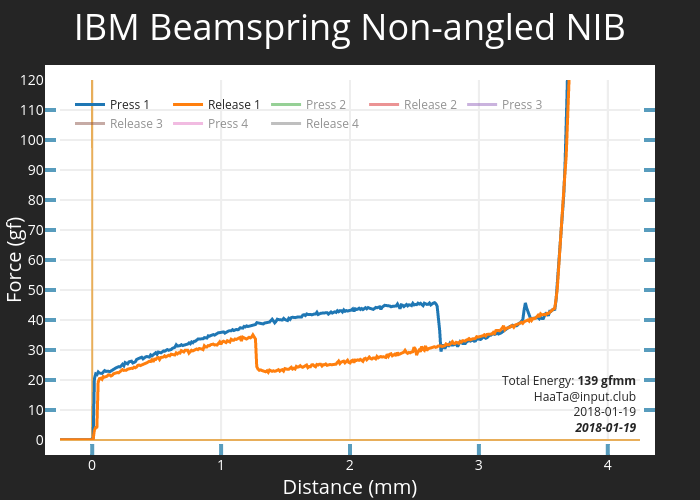

https://plot.ly/~haata/454/ibm-beamspring-non-angled-nib/

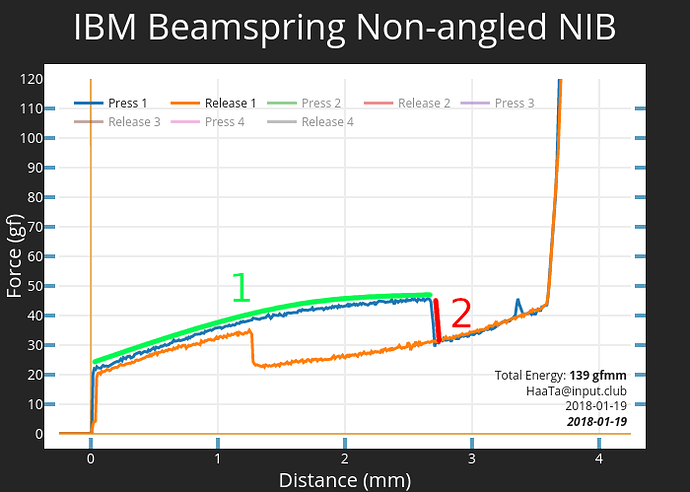

(New Old Stock IBM Beam Spring)

There are two key force properties that define a beam spring switch.

The first (1) - Force increases, but tapers off similar to a parabolic force curve.

The second (2) - Once the force is no longer increasing (maximum resistance of the beam) the force is suddenly inverted and any stored energy is released (partially in the form of sound). This results in a sudden force falloff during the press, providing a characteristically sharp but natural feeling tactile event.

When pressing a generic linear switch (Kailh Red) you anticipate that pressing harder will result in more movement. This does not provide any activation-related feedback for typists, requiring you to observe a result on your screen for confirmation. Standard tactile switches (Kailh Brown) also have an unnatural-feeling force distribution, though they do offer tangible feedback. Most tactile switches use rapidly increasing obstructive force to create a tactile event, which will essentially jam a key into your fingertips. This can sometimes obscure resulting force decreases that would otherwise contribute to good switch feel. It also requires the use of additional tactile leaves or elements, which cause unwanted friction — reducing smoothness.

Beam Springs help the press feel softer and more refined by using a tactile force dropoff. As the force is decreasing at the tactile event, rather than increasing, the switch will seem easier to press. We paired this natural feel with our signature bottom-out resistant ramp at the end of the press to offer the best of parabolic and linear force curves. No tactile leaf is necessary in this design, so smoothness is increased.

Plus it’s impossible to forget about that click! Beam springs are known for being exceptionally distinctive and satisfying. Here’s a comparison sound test of 4 different switches (in order): Kailh BOX White, Silo Beam, Kailh Blue, Kailh BOX Navy

Silo Beam Switches

Silo switches are the culmination of two different projects Input Club has been working on for a number of years. The first, designing an analog Hall Effect keyboard switch. The second, how to modernize a Beam Spring switch and mold it into Cherry MX-like dimensions.

I’ll be writing another article solely on analog switches in the near future, so stay tuned by joining the mailing list for these projects - Keystone Mechanical Keyboard Waitlist!

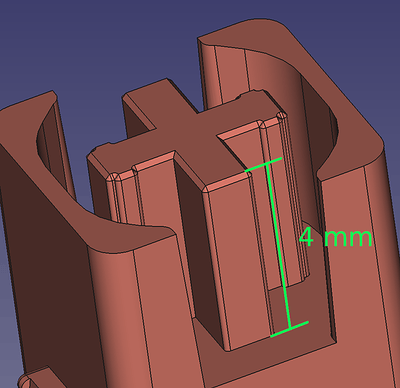

Compacting a Beam Spring mechanism into something similar to a Cherry MX switch has a lot of challenges.

First, IBM Beam Spring switches are huge by modern switch standards. By making the switch tall IBM was able to stack two different springs (coil spring and a beam spring) and allow room for the capacitive fly plate to move up and down. The activation mechanism is attached directly to the tactile/click mechanism — reliability increases as a result. As a counterpoint, Kailh BOX White switches may not have their click aligned to switch activation, as the click bar has nothing to do with the contact leaf that turns the switch on and off. Contact switches also lack an adjustable activation point, which creates limitations for typists with different preferences.

For Silo switches, the click has been separated from the sensing technique as well (magnetic sensing). Unlike contact-based switches, however, Silo switches have adjustable activation and deactivation points via their Hall Effect sensor field strength data (magnet distance from sensor). This means you’re not limited to a set position when riding the activation point. Using the linked graph for the Beam Spring Prototype as an example (Beam Spring Graph), if activation was set at 2.2 mm and deactivation at 0.8 mm you would have to press / release 1.4 mm x 2 = 2.8 mm to do a double tap. This creates significant flexibility for typists vs. a contact switch — which is stuck at a single activation point that may not match your typing style. Contactless sensing also eliminates contact leaves, resulting in more room for a beam spring and its resulting clicky goodness.

Next — keycaps! In our opinion, Cherry MX keycap mounts aren’t an optimal design. They are the keycap standard, though, so we’re working around them in our projects so you can keep using fancy keycap sets with our keyboards. The main challenge of integrating a beam spring switch is actually having enough room to place the beam and tensioner somewhere inside the confines of a Cherry MX-sized housing. The keycap mount plays a role in this, as it must fit inside the switch when pressed.

When designing keyboards, It’s impossible to forget the most important feature of any modern keyboard: backlit RGB LEDs . Joking aside, any modern switch that doesn’t consider backlighting isn’t a complete work. I became a keyboard enthusiast and designer (specifically while learning Colemak) because I was frustrated that I couldn’t type well in the dark. Silo switches will support dual LEDs (North and South orientation). Silo switches will also support switch rotation (180 degrees), so this was doubly necessary. If you’re one of those people with absurdly thick keycaps (which can impact switch housings in certain orientations) you’ll be able to hotswap-rotate your switches any which way you’d like (the pictured prototype doesn’t have this feature yet, but we should have the next round of samples soon).

Why can’t I use these on my existing board?

Standard MX type keyswitches are either soldered or socketed into keyboards. More specifically, they are contact based, and the contact mechanism is intrinsically tied to the feel of the keyswitch. As part of us wanting to improve on existing technology, the Silo switches are contactless, using Hall Effect sensors that require entirely different circuit board designs.

There are a couple of advantages to this approach:

- All clicky and tactile mechanisms are decoupled from the activation point. This magnetic analog system allows you to customize activation points.

- Linear mechanisms are extremely simple, and they do not need physical contacts like MX-type switches. This results in an extra smooth feel due to reduced surface friction.

- Contacts, being mechanical in nature, will eventually be subject to certain types of failures. Oxidation, stress cracking, and friction-related wear are a few examples. Hall Effect sensing, on the other hand, has been rated into billions of actuations (Honeywell Hall Effect Design Manual) for linear switches due to their contactless design.

- Swapping switches is extremely simple, and can be done any number of times. For contact based switches, there’s either tedious desoldering/resoldering involved, or usage of sockets. While sockets were a major improvement on the status quo, they would eventually fail if someone tried to swap switches hundreds of times.

The end result? A switch that is fundamentally incompatible with existing keyboards.

Where can I get them!?

The first mechanical keyboard showcasing Silo Beam switches will be the Input Club Keystone. It will also offer tactile (Silo Command) and linear (Silo Control) variants. More details about Command and Control switches will be available in the future.

PCB and firmware design will be our task for the next few months. Analog Hall Effect sensing is a groundbreaking concept, so it will take our team some time to design a home for these switches. It will also take other companies (and us) time to iterate on the design and create Silo-compatible keyboards in smaller form factors.

If you really want to try Beam Spring switches right now, it might be somewhat tricky. Beam Spring keyboards are hard to find, very expensive, always used (your keyfeel won’t necessarily reflect the NOS curve above), and typically in need of significant refurbishment. They require a custom after-market keyboard controller and possibly a new PCB as well (xwhatsit xwhatsit's Grand Unified IBM Capsense USB controller thread or Common Sense (https://deskthority.net/viewtopic.php?f=7&t=13988) to use with USB. Most Beam Spring keyboards have odd keyboard layouts not really designed for modern computing, and weigh something like a couple of bricks. Your best bet may be to head to a local keyboard meetup — someone may have one you can try.

IBM Beam Springs

(ChyrosRan22)

(ChyrosRan22)

(Mattias Schoeffl)

IBM Beam Spring Restoration

IBM 3278 Beam Spring restoration - deskthority (darkcruix)

(Wodan)

Please join the Waitlist for the Input Club Keystone Keyboard

Input Club and Kono rely on your support in order to work on super cool projects like these. This is something that I thought was pretty much impossible from a manufacturing perspective even a couple years ago. I’m super thankful for your support!

— Jacob / HaaTa