Finally getting around to tuning up my switches for my E6.5 build today. I decided on MD HP’s with Halo Clear stems, 70g TX springs, white switch films, 3203 for lubing the housing/slider, & TX’s springs oil that comes with them (it is a paraffin synthetic oil). So far I’m pretty impressed with the TX oil, it really quiets the springs down big time without affecting the feel at all. Gotta see how well it holds up over time yet, but if it does I think I found my replacement for VPF1415!

Speaking of TX springs and oil and whatnot, does anyone know how TX’s custom Krytox blend performs?

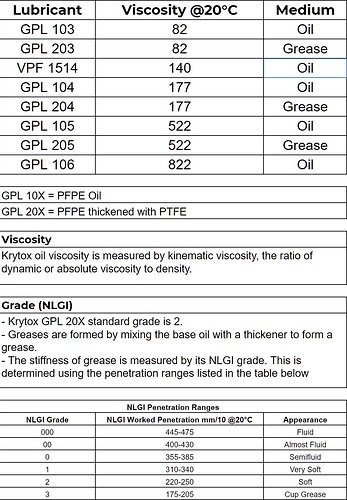

Really, for that matter, we need some lube experts to get a big document or wiki or something that puts all of the lubricants on a scale to show their properties, or at least an explainer on what the manufacturer’s spec are. I still don’t know the difference between the Krytox grades and what the numbers mean.

I’ve got a chart floating around somewhere that I think @Walkerstop put together with a bunch of different grades and brand. I’ll see if I can find it!

Thanks for that amazing tuto ! I’m going to build a new keyboard with vintage Brown and all that information will be very useful

As far as Krytox numbers go, Store Uni has some good info on their product pages for it. e.g., for the grease grades:

| NLGI Grade | Appearance | Consistency Food Analogy |

|---|---|---|

| #2 | Normal Grease | Peanut Butter |

| #1 | Soft Grease | Tomato Paste |

| #0 | Very Soft Grease | Brown Mustard |

| #0S | Softest Grease | |

| #00 | Semi-Fluid Grease | Apple Sauce |

Here are a few numbers. They don’t really mean anything until you’ve tried at least one to get a baseline idea of what the consistency is like.

I think I’m following in your footsteps here. I’ve lubed quite a number of Tealios with 205g0 so far, and haven’t yet been happy with the results. After reading your comments here, I’m trying to apply even less 205g0. I know this might be a tough question, but do you know of a good way to tell when you’ve applied just the right amount of 205g0 to a Tealio? Should I barely be able to see the lube after applying it?

Not OP, but hopefully I can help a bit. IME with 205G0 less is definitely more. You basically want the thinnest possible layer of lube on your parts. I use a size 0 or 00 artist brush to apply lube & what I do is dip the brush in & get it almost completely covered with the lube then wipe as much as I can off the bristles on the side of the container (this may need done a few times when starting to get the lube worked all the way through the brush’s bristles). Next I’ll start lubing the part, let’s say the slider for example, by starting on one side & painting the thinnest coat I can then repeat for all four sides. Once that is done I will go over all the sides again real quick with the brush to make sure the lube is as consistent as possible on all sides. Then hit the underside where the spring will sit & stem, all this is done with just that tiny bit of lube left in the brush after dipping & wiping it off to give you an ideal of how much you should be using.

When you’re done you should barely be able to see the lube, any globs or really thick layers is gonna cause that switch to feel inconsistent to the others. My personal trick for knowing when I got the lube on thin enough is when you have angle the part you are working on towards a light to see the lube. There is no real way of knowing when you have the right amount, you just end up getting an eye & feel for it after doing it enough times. Although the more times you work over a set of surfaces without putting more lube on your brush, the thinner & more even the coat of lube will be on those surfaces. Hope this info helps you out some!

Edit: Also I should clarify that when I lube my switches I lube the springs (with an oil different from the switch lube usually), all contact surfaces on the bottom housing, all contact surfaces on the top housing, & the whole slider (sans the cruciform mount on all stems & actuation legs with tactile stems).

Yes, that’s basically it. Thin brush and good lighting is helpful. Also just take your time. I’ve ruined many switches being in a rush.

And if you don’t want to put in that kind of effort or are feeling lazy, just go 105g0. It’s way more forgiving and it works great with Tealios.

Wow, thanks so much for the detailed response! That advice is really helpful, and definitely gives me a good idea in terms of how much lube I should be using. I’m going to give your approach a try in the next couple of days!

Good lighting is a really good tip too, thanks! I am curious about lubing the whole thing with oil as well. I’ve got some 106 I’ve been using for springs, so I might try lubing a switch or two with that as well.

Where are you guys getting Krytox 106? I have 104, and I want to test more switches with that, but since 106 is apparently so good, I’m really heavily considering that. It may also save a lot of time lubing, because of it’s fluidity spreading across the switch better where IME grease doesn’t quite have that same quality.

No problem, let us know how it goes!

I got mine off eBay. ~$25 for 1oz bottle. I think same vendor also sells through Amazon. StorUni also sells them.

I got mine from StoreUni. They’ve changed their website address, but you can find the updated page for 106 here.

So I finally got finished lubing the Tealios with 205g0 using the approach you suggested, built a board, and the result is awesome! I’ve been typing on it for about a day now. It’s really smooth, none of that sluggish feeling I was getting before, and the sound is quite good too. On the overlubed switches, I feel like I could hear an additional “scratchy” noise - maybe the stem moving through the extra lube? Anyway, that noise is gone too. All in all, a HUGE improvement.

Thanks again for sharing your method - it’s definitely a game changer for me!

Awesome to hear bud! Really glad I could help you out some & now you got switches you are very happy with!  Also it’s no problem at all, helping fellow enthusiasts is what this community is all about to me. So always feel free to hit me up for advice if you need any in the future.

Also it’s no problem at all, helping fellow enthusiasts is what this community is all about to me. So always feel free to hit me up for advice if you need any in the future.

As far as the scratchy sound that was happening when you had them overlubed, it was either like you suggested just a sound from the stem moving through a ton of lube. Or the stem may have gotten pushed closer to one side of housing cause of the excess lube & was dragging hard on that side. Hard to say, but you don’t gotta worry about it anymore! Anyways enjoy the refreshed switches man!

The usual rule of thumb with grease is that if you see any white substance on the switch, you’re using too much.

You won’t get the best results straight away. In my experience it takes about two weeks for the grease to spread, to fill all the holes and for the excess to be pushed to the sides.

You could also try a less viscous lube like 202 or 204 (both if which I sell within Australia).

Very good point I don’t hear mentioned often! When using thicker greases (& even thicker oils like GPL107) there will be a “break in period” where they feel a bit sluggish & give off some unwanted sounds while the parts move the lube around to where it wants to sit at.

That’s a really good point about it taking a couple of weeks for the grease to spread. I think I’ve often expected the board to feel “perfect” as soon as it’s built. I’ve noticed anecdotally that the feel changes in the first couple of weeks, but it’s good to hear that that’s a normal experience for others as well!

I feel like I’ve got the hang of 205g0 now. My first attempt at lubing was retooled MX Blacks with Tribosys 3204. It didn’t seem to require too much skill, and I was happy with the result. It got me interested in exploring linears more. But it definitely took me a while to get a result I was happy with using 205g0. @Rob27shred’s advice was super helpful.