Build #18: Singa R2

When I originally came up with the idea for this build, it was really envisioned as an exercise in color pairing. I liked the idea of an orange case together with brown caps, to play off of the shared earth tones. And if this hobby wasn’t as group-buy driven as it is, that might have been the only thing to talk

about - here, look at the photos, colors, hooray. Next.

But those group buys, and the long waits that come with them, give the build time to grow. When I first imagined this build several months ago, a number of things weren’t, well, things: affordable Holy Panda components, easy availability of replacement plates using different materials, the use of scuba-gear lubricants for switches and stabilizers, and, perhaps most importantly, my experience with a few builds between then and now. Put all of that together, and this build became a lot more interesting (for me, at least). Let’s get to it.

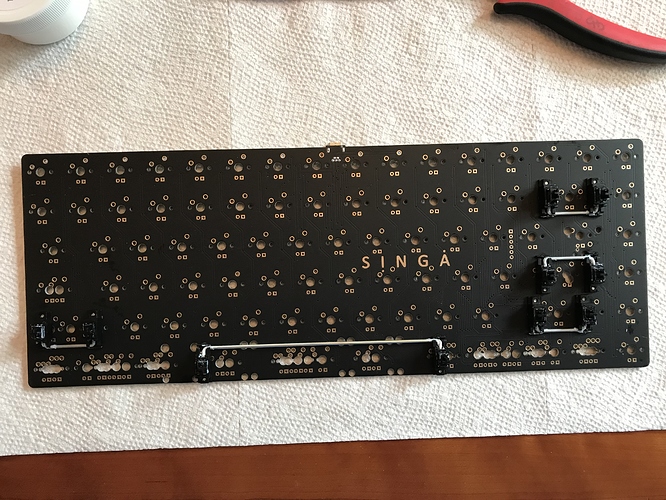

The Singa R2 PCB supports a number of layouts, but if you’ve opted for the WKL top with blockers, your bottom row is going to have a 7u spacebar, 3 1.25u keys, and 3 1u keys, which you will be using as arrow keys. That, in turn, means you will have a 1.75u right shift to make room for the up-arrow key, which means you don’t need a stabilizer for right shift. Straightforward, right? Let’s get set up

for some stab work.

For this build, I wanted to try Christo-Lube 111 for stabilizers. While I’m more or less happy with SuperLube for stabs, and feel like I can achieve acceptable results with it, it can take a bit of tuning to avoid sluggishness on the stabilized keys. The word on the street indicated that 111 killed all the rattle

and noise without affecting travel. Coupled with the low cost of 111, that made it worth a try in my book. As far as consistency goes,111 is relatively stiff. It clings to the side of the jar and holds its shape, and while it’s not stiff enough to hold a dental applicator upright, it has enough grip to keep the applicator from sliding out of the jar. 111 is also noticeably less greasy to the touch than SuperLube, and less dense.

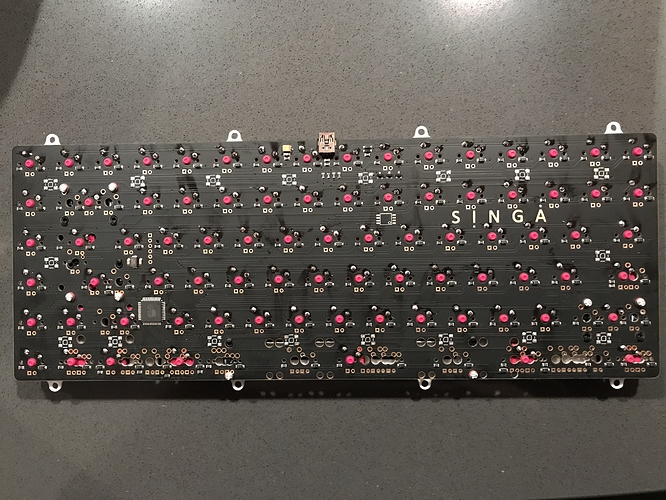

Because of the lighter density, I felt comfortable applying the lube more heavily, certainly more heavily than I would apply SuperLube or Permatex dielectric grease. It’s difficult to capture that in a photo, but hopefully the left stab housing on the 7u stab gives you an idea:

And, there we are, lubed stabs installed. All good. Wait, what?

I wish the “build log writing” me, the one that outlined layout considerations for you, had been present when the “keeb building” me blithely lubed that extra 2u stab and installed it on the right shift. Sigh. Let me just unscrew that and we’ll pretend that never happened. Look on the bright side - if 111 works out, I have one less 2u stab to lube for the next build!

In the previous build log for the tx108se, one of the least pleasant aspects of the build was insertion of switches, switches with Panda-style housings in particular, into the brass plate. Panda housings are known to be slightly wider than other MX switch housings, and the tolerances on the TX plates are known to be tight. I ended up bruising my thumbs pushing switches into the plate, and from what I had seen online regarding Singa builds, I was not looking forward to repeating that experience. Fortunately, by the time I got around to this build, an interesting option had emerged.

Rather than use the sandblasted brass plate that came with the Singa kit (which, granted, is lovely), I picked up a POM plate. In addition to being far easier on the fingers when mounting switches, this also gave me an opportunity to check out the sound signature of POM, something I’d been itching to try for a while. I’m also finding that I’m not a big fan of brass plates, as they feel too unforgiving for me. Feel is subjective, of course - YMMV. Tolerances were good, and stabilizer housings lined up cleanly with the cutouts.

81 Holy Red Pandas, ready for action…

…and soldered in place. I didn’t use either the bandaid mod for the stabs or any Sorbothane between the PCB and the plate, as I wanted to get a clean impression of POM’s sound, and I felt that with a top-mount board, if any sound dampening proved necessary, a bit of Sorbothane between the case and the PCB would be sufficient.

Top-mount installation is straightforward on the Singa; just screw the plate into the recessed screw holes on the underside of the top of the case.

Attaching the two case halves is also straightforward; the case bottom has eight screw holes through which the top can be attached to the bottom.

You can see the holes here, as well as the cutouts on the sides for lifting the board, but the real reason for showing you this view is clear - just look at that polished lion’s head weight. Gorgeous.

On initial assembly and testing, I found that there was some metallic case ping on key impact, so I opened the board back up and applied Sorbothane. Normally, I’d cut a few thin strips, peel the plastic backing, and wrap the strips in gaffer tape before placing them in the case, but when I realized I had spare sheets that more or less matched the case shape, I just went with it, and left the plastic backing on, to avoid getting any plasticizer on that lovely weight. You can see the pressure points in the center sheet where the switch pins are pressing down, and I’ve been finding that’s about the level of compression I like to see for best performance.

Finally, one last bit of work before the board is ready for prime time. While the Singa supports QMK, the PCB uses a ps2avr bootloader and an Atmega32a controller, so I couldn’t use the QMK Toolbox to install firmware in the usual way. Fortunately, the readme.md file in the keyboards/singa directory of QMK gives clear instructions for downloading and using the HIDBootFlash tool, and after building the firmware with the keymappings I prefer, flashing the resulting firmware proceeded exactly as described in the readme. Always a good thing.

From the moment I saw the burnt orange tone of the Singa, I thought Chocolatier would make an excellent pairing, capitalizing on those shared earth tones. The RAMA Golden Ticket artisan adds a nice accent, although I discovered that it’s heavy enough that keystroke feel is affected; much less pressure is necessary to cause the switch to trigger with this cap. My kitchen scale doesn’t have sub-gram precision, but a single GMK cap registers as 1g, while the RAMA cap registers as 12g - so even allowing for measurement error, it’s not surprising that this would happen. Easy enough to fix, if I can decide which way to go with the modifiers…

Lessons learned

- I’m enjoying the POM plate - nice, crisp sound (and way easier on the fingers than the brass plate, although I will grant you that the brass plate looks better with the color scheme. Sometimes, there are unavoidable tradeoffs to be made).

- Holy Pandas on POM - this is a nice combination. While I wouldn’t say there was really much flex on the Singa, typing feels noticeably more forgiving on bottom-out than the Pandas did on the brass plate in the tx108se.

- At least for this build, I’m not missing the bandaid mod, nor the usual dampening I would apply between the plate and PCB. I don’t have enough experience with top-mount to know if this result will generalize to all top-mount boards, but it’s something to evaluate further.

- Stab lubing with 111 - I like it quite a bit, enough that it is a serious contender to replace SuperLube as my stab lube of choice. Eliminates all rattle and undesirable noise, but stab motion is not sluggish in any way. The sound and feel of the non-spacebar stabilized keys is quite consistent with other keys, probably the most consistent I’ve observed in any build. I’ll be trying this again soon.

- WKL blockers: the aesthetics vs functionality tradeoff is real. The bulk of my time is spent in front of Windows, and not having a Win key is like missing a finger. Yes, I know we can remap keys, and I’ve done so here, but decades of muscle memory make this a difficult proposition.

- I don’t use artisans often, but when I do, I need to check the artisan weight and adjust spring weight in the appropriate switch if the artisan is substantially heavier than a normal keycap.

So what would you pick here to set off GMK Chocolatier - the RAMA golden ticket cap…

…or the yellow accents? Choices, choices…

Specifications

case: Singa R2 anodized aluminum (burnt orange)

case dampening: 0.1" 40 Duro Sorbothane sheets

PCB: Singa/TGR PCB (ps2avr)

plate: POM

LEDs: n/a

switches: Holy Red Pandas

- YOK Red Panda housing & springs

- Halo Clear stems

switch lubing:

- manually lubed housings/stems with Tribosys 3204

- tub lubed springs with Krytox GPL 104

keycaps:

- GMK Chocolatier

- Rama Golden Ticket

stabilizers: GMK screw-in (1x7u, 3x2u)

stabilizer mods: clipped, lubed with Christo-Lube MCG 111

plate/PCB dampening: n/a

HxWxD (without caps): 1.38"x12.25"x5.13"

HxWxD: 1.69"x12.25"x5.13"

assembled weight: 4.78 lb