Build #23: Norbatouch Pi Astrophysical Purple (Laser Trio 3/3)

For the last of the Laser Trio, I’ve had a specific build in mind for a while - a pairing of GMK Laser with a Norbatouch, in the Astrophysical Purple finish. Certainly not a novel idea; even a brief bit of googling will reveal other builds with this exact pairing. Still, the reds and blues of Laser and that powder-coated purple just make sense to me, and I wanted to see it in real life.

For this build, I used a CoolerMaster MasterKeys Pro S as the donor, and I’ve covered the build process for combining a MasterKeys Pro S and a Norbatouch Pi in exhaustive detail, so this log will be comparatively brief. Here we see the donor board with keycaps removed.

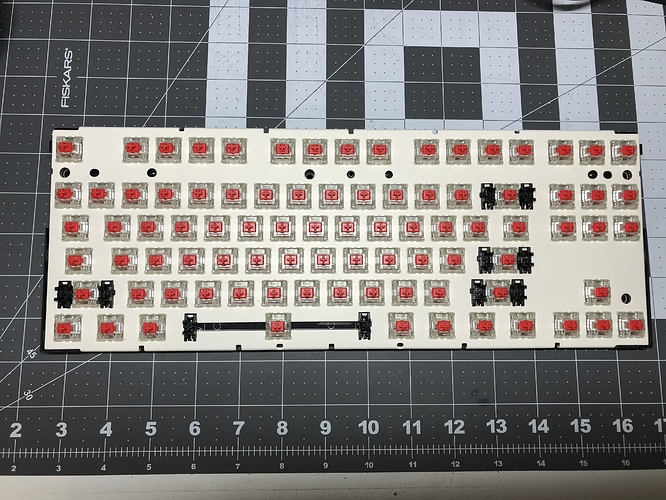

And here, we see the plate/PCB assembly.

As with the previous Norbatouch Pi build, we desolder the existing switches (in this case, Cherry Reds), remove the OEM stabs and replace them with clipped, lubed, and O-ring modded GMK plate stabs, solder in new lubed switches (62g Sakurios), and install Sorbothane struts between the plate and PCB. The result of all this work may not look radically different, but the feel and sound is another matter entirely. Smooth…

And, following our previous approach, we wrap pieces of Sorbothane in gaffer tape and place those between the PCB and the case before screwing the case halves together. With that done, we get our first look at the board, sans keycaps:

The MasterKeys Pro S PCB has north-facing LEDs, and we’ll be using GMK keycaps, so we need to apply washers to clean up the sound on rows 2 and 3 (the Tab and CapsLock rows). In this case, we’re using washers from NovelKeys, which means we need two washers per key. Here, you can see the installed washers on the H key. These washers are very thin, and tend to cling together - it’s easy to think you’ve installed two washers, and later realize you’ve installed one or three.

Lessons learned

- I’ve mentioned it before, but I really like the O-ring mod on plate mount stabs; it’s very hard to distinguish the sound of stabilized keys from regular keys with this mod in place.

- I have a strong preference for tactile switches, but the lubed Sakurios are really smooth and pleasant to use, and I’m finding the lighter 62g weight more enjoyable than I was expecting. Coupled with the thock that the Norbatouch Pi and the Sorbothane contribute, this might well be the first linear board I enjoy using.

- Christo 111 works just as well on plate-mount stabs as it does screw-in stabs.

- Don’t forget to use washers on PCBs with north-facing LEDs and GMK caps. Once you hear the caps hitting the switch housings, you won’t be able to unhear it, and washers get most if not all of the sound back.

Before we move on to group photos, let’s take a quick look at the final board. Gotta love that purple…

Specifications

donor board: CoolerMaster MasterKeys Pro S RGB

case: Norbatouch Pi (Astrophysical purple finish)

case dampening: 0.1" 40 Duro Sorbothane, stacked to 0.2", wrapped with gaffer tape

PCB: donor

plate: donor

LEDs: per-key RGB, integrated in PCB

plate/PCB dampening: @donpark Sorbothane strut mod, 0.25" 50 Duro Sorbothane

stabilizers: GMK plate-mount

stabilizer mods: clipped (all four legs), lubed with Christo-Lube MCG 111,

and O-ring modded

switches: replaced donor Cherry Reds with 62g Sakurios

switch lubing:

- manually lubed housings/stems with Tribosys 3204

- tub lubed springs with Krytox GPL 104

keycaps: GMK Laser

- Cyberdeck, Mitowaves

HxWxD (without feet or caps): 1.0"x14.63"x5.75"

HxWxD (without caps): 1.63"x14.63"x5.75"

HxWxD: 1.93"x14.63"x5.75"

assembled weight: 4.59 lb