foam is soft - also why case foam? the tape mod was created to not have the deep sound swallowing foam - as far as I understood it

Notes from tape modding some of my keyboards:

- Improved loud clacky builds, lowering pitch and softening peaks. Cream sound changed from ear slapping to knuckle tapping.

- Enhanced gasket-mounted board, lowering pitch while making switch sounds more audible.

- Plate material seems to affect mod effectiveness a lot. Brass plate builds came out good while POM plate builds all kinda sucked.

any news on this?

I am not so sure about why the tape mod is working.

My reasoning is that FR4 does not give back too much vibrations that can be heard.

So just guessing that tape mod affect plate sound indirectly because the switches, plate and PCB are all connected together. But hey it is just a guess and I may be very well wrong…

As anyone tried to tape mod the back of the plate instead ?

I am curious to hear if the result is the same, maybe even better, or if it does not improve anything.

I have a theory, based in nothing other than cursory knowledge of how sound travels and so am probably wrong.

Case foam acts as a dampener, all it really does is reduce loudness and slightly alter the sound.

Plate foam alters the sound because it has to travel through the foam in one direction and sound travels at different speeds when it moves through different density materials.

Tape and PE foam mod are the equivalent of adding a low/high pass filter. It is subtracting out very specific ranges that alter the sound very differently from other mods.

Ye, kind of like the filter ppl have with there microphones. It’s just a thin piece of fabric but it makes all the difference.

Recently joined Keebtalk and damn! I wish I had known this group earlier. So much knowledge here @.@

having used sorbothane and foam in the past, tape mod with foam between plate and PCB is by far my favorite, cheapest too, which is rare. I did four layers of heavy duty packing tape on the back of my h87a on a board that usually sounds hollow…the result is a great sounding board with no hollow sounds.

The clear heavy duty packing tape definitely works for sound, I suppose I may be cussing if I ever have to remove it. Though I plan to use my heat gun to loosen the adhesive if I do ever have to remove and I suspect it will come off quite easily with sufficient heat.

Hmm new product seemed to pop up pretty fast from kbdfans. I wish shipping wasn’t do expensive

Edit: I am curious if that will even out around milmax sockets as that’s my biggest reason for not using them

hmm, seems promising. so what if you combine this with plate foam and tape mod? I think it could be a great way to shore up the sound in a tray mount case. I have a beautiful blue TEX case that I’ve owned forever, but I never have anything in it b/c it sounds so harsh. Might be a good fix!

Just need to make sure the plate foam is not too thick or this + the foam might keep the pins from coming through the back of the pcb. lol

Couldn’t you use the ones for hotswap if you’re worried about milmax fitting through? They have larger holes for the pins

Not exactly what I meant but that is a good point too.

Milmax cause switches not to sit flat on the PCB. The new big bucks millmax sockets probably don’t suffer from this as much

Soo, have any of u guys made a underglow friendly tape-mod? Did it work out?

while probably not a lot of fun it seems like you might be able to hole punch some painter’s tape to open up the tape where the underglow LEDs are. Potentially you could hole punch the edges of the tape and then run the tape along either edge of the under glow row.

I basically did a crude version of this yesterday with a screwdriver and some scissors, to make room for standoffs, a battery connector, etc.

This makes me think though - I wonder if it would be worth having die-cut adhesive sheets for popular pcbs… I might have to try this mod with plotter-cut vinyl.

I have used something similar in project before (though I didn’t have a plotter/cutter – wish I did). Google “Oramask 813 Stencil Film” if you are unacquainted

Oh, man - that looks perfect. Well. I have a new project. :3

It looks like there are three varieties of film at that thickness and low-tack adhesive strength, with 810 being for “uneven surfaces” - I might see how that does with the bottom of a PCB. The wide masking tape roll I have does okay, but falls off without something to hold it on.

Edit:

On further inspection - maybe I should go with the 813 after all - it looks like 810 uses a solvent-based adhesive, while 811 and 813 use water-based. I’m not sure how well that adhesive would play with things like hot-swap sockets.

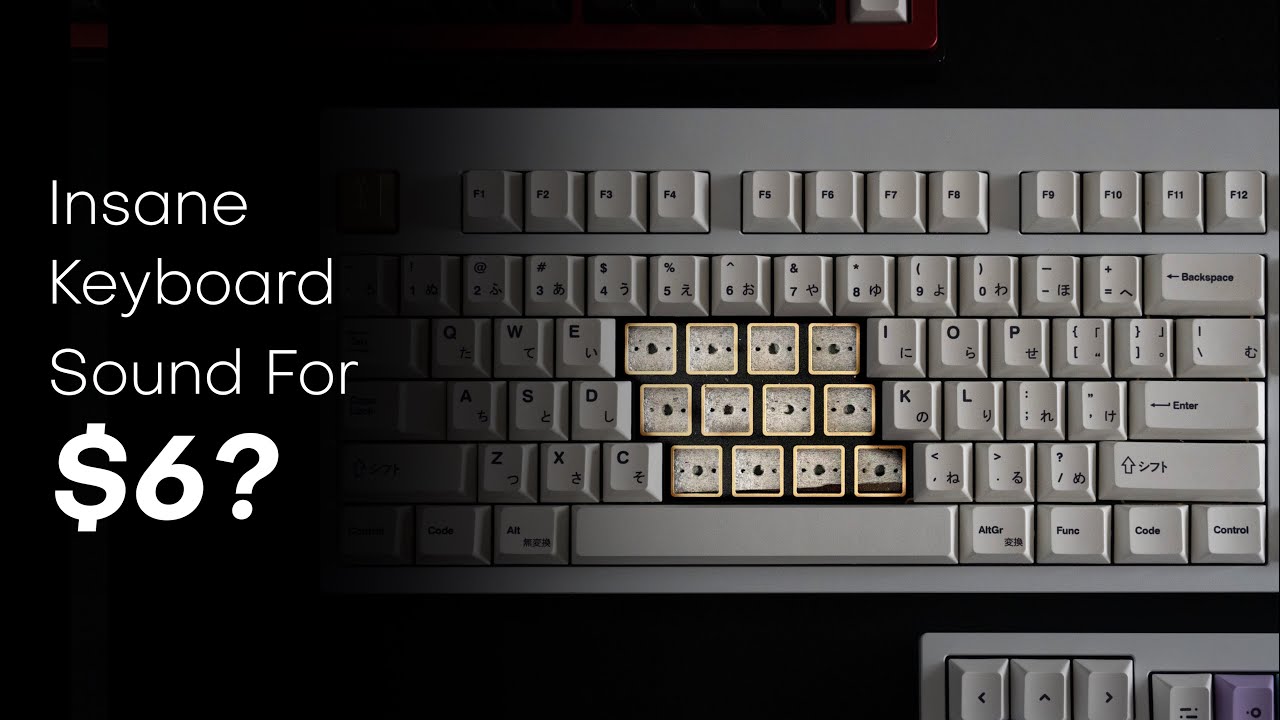

A bit more detail on the tape mod from nearLucid, as well as details about PE foam between the switches and PCB - a DIY version of those KBDFans switch pads.

All really interesting experiments! I think what I take away from this is don’t get hard set on any foam or tape mods until you try them out. Bc you might end up with something that doesn’t sound like what you wanted. Start by raw dogging it, and if it sounds bad, add stuff.

Definitely makes sense that the PE foam has a big effect. You’re absorbing vibrations from the switches before they can travel through the PCB. The PCB is basically a drum head on many mounts, so limiting what gets there seems like a good idea if you’re going for a refined experience.