Perhaps more a mildly interesting hmmm than anything else:

The first thing I noticed is that the progression of the bumps reminded me a bit of stock Halos, at least in terms of how a rising cushion seems to follow the bump itself. I put a pin in that, noting this may make the steams great for frankens after all - experiments on that to come.

The next thing I noticed is that, trying these two switches in-hand, they’re at least as different as their sales pages say - but something about them feels very related. I wondered then and there if they might have the same stem. Time to pop them open and see what I can see.

After some fairly brief experimentation, I’m reasonably convinced that the only functional difference between Akko’s Ocean Blue and Lavender Purple switches is the spring.

da springz

As I’d mentioned in the mailday thread, I got these out of curiosity, both when it comes to their stock performance and their frankenswitching potential. First impressions of both as stock switches are very positive, with the exception of some serious ping - excusable at the budget price. Generally, these appear to perform great for what they cost. More details on that another time - this post is about something more specific.

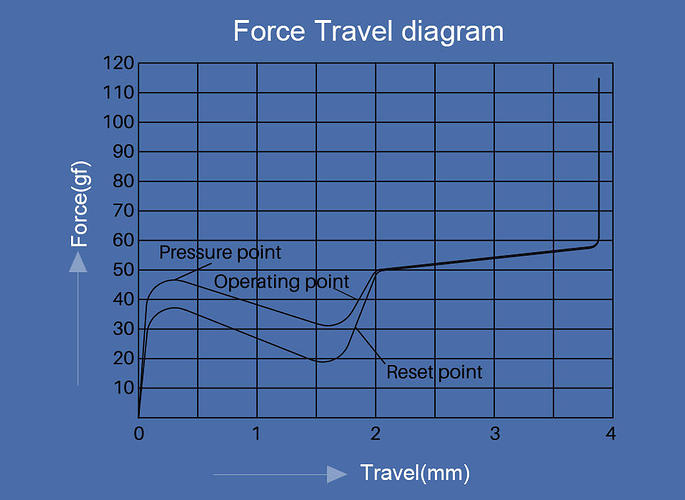

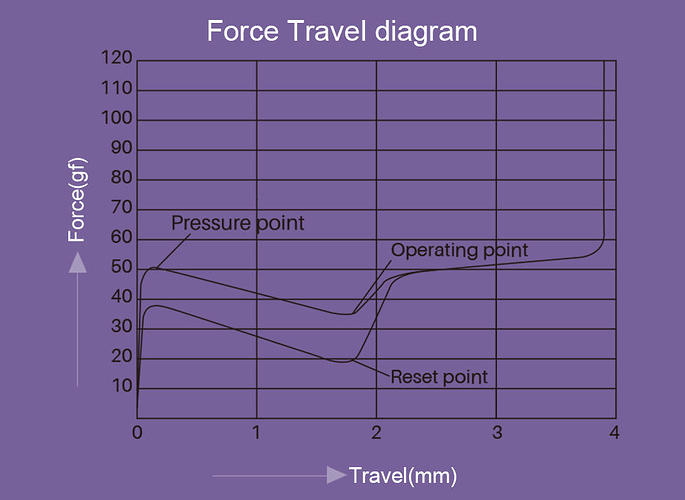

I’d like to start by looking at Akko’s own supplied force curve graphs from the product pages.

Ocean Blue:

Lavender Purple:

Always a grain of salt to be taken with brand-supplied diagrams, and I’m not sure how accurate they are, but I’d say they’re more or less descriptive of how they differ.

They already look fairly similar, but give the impression that the Purp has a sharper onset - which it does. At least based on some past experiences, these graphs hinted to me that the Blue might have a more rounded stem or mild leaf compared with the Purple - but after swapping around some components between these two switches, I think it really is just the spring.

Honestly I think that’s quite clever in terms of cost-saving measures in context of developing a line of switches. Using one tool for multiple switches saves a lot - and the more parts you can keep the same, the lower the cost will be. These switches seem to be a case-study on just how much one part that isn’t the leaf or the stem can change the character of a switch.

Kailh-made Halos and Polias are very similar. I believe these are completely identical.

There are some nuances about the stem design in general that I like; the rails seem to be thoughtfully shaped in multiple dimensions, with a high level of detail and control over the bump’s shape. This makes sense not just for trying to make a quality switch, but especially when developing a stem meant to carry multiple switches.

In case you’re wondering about it specifically, yes, I believe even the leaves are the same between these switches. It appears the springs alone account for their differences not just in weight, but in the character of the bump itself.

Ever have that feeling when researching a thing, when you realize the thing is much deeper than you thought, and there’s a simultaneous excitement for the opening possibilities and intimidation from the newfound complexity?

A chicken-walk that I promise is related - or more specifically, a random walk. Given an infinite number of steps moving one at a time in a random direction from one point on an infinitely large two-dimensional grid to another, it is 100% guaranteed you’ll return to the same point sooner or later. That guarantee goes right out the window if that grid becomes three-dimensional, even given an infinite amount of time and steps to return. Might happen, might not.

This illustrates how much more complicated the science of tactile bumps just got in my mind upon fully recognizing how much of a role springs can play.

I’ve already been surprised by this in the past, and noted it here and there, but I don’t think it had really sunk-in how much / how many of the bump’s qualities can be dialed-in and adjusted purely through the spring.