Mine is I forgot to put the plate on the Qaz I’m building before soldering the pro micro because I was so excited that I successfully loaded firmware on a pro micro for the first time and wanted to test it  from now on I’ll be known to prefer plateless builds to maintain continuity.

from now on I’ll be known to prefer plateless builds to maintain continuity.

For me, i pre-order another keystet, i know that i have way more keysets than keybaords

Ordering cool shit I don’t need. Always ordering cool shit I don’t need.

The two PCB’s I killed learning to de-solder ? I chalk those up to learning experiences.

But the 0.3mm of play in my stabs? That bugs me.

I’m the opposite. More keyboards than keycap sets

i know that i have way more keysets than keybaords

Well, easily solved. You just need moar keyboards!

I bought 2 HHKB Pro 2 Type S for 150 (which is really cheap), and sold one for 140, meaning I got a basically free HHKB Pro 2 Type S. Does this mean I’m a flipper?

Trying to imagine what a keycap set would look like on one of my boards. Instead of getting the actual set out and putting it on a board, I google images of the combination. That’s some shameful laziness right there.

Mine is turning out to be buying the GMMK Pro.

It’s a pretty board, nice to type on, but hobbled by their software implementation that is making customization an unnecessary challenge.

I got two macro pads today!

No I didn’t!

Turns out I ordered two empty cases that only fit one PCB model that isn’t sold by itself.

Well. I do have a spare Pro Micro… Maybe this is an opportunity to learn to hand-wire, or burn a PCB.

It’s an opportunity to learn KiCAD and order cheap prototype PCBs! ![]()

If PCB design and manufacturing is your day job and you wanted to go full artisan for a change, please disregard my suggestion and handwire some PCBs. ![]()

I’ve honestly been wanting to learn more about it for a while. My dad is a major electronics hobbyist, and I’ve watched him make circuit boards for personal projects since I was a kid. I’ve always thought it was cool, but until more recently with keebs, it hasn’t directly overlapped with any of my own interests.

He uses an acid etching process to make his boards, starting with copper-coated FR-4. He used to start with a laser-printed heat-transfer sheet, but these days he uses plotter-cut vinyl as the etching mask. I’ve thought for years it would be so cool to do a handmade circuit board for a keeb as a collaborative project.

That’s a nice family activity! Design a board in KiCAD, let dad review it and export Gerber files for him to plot. Then build it together and learn from his experience. Win-win!

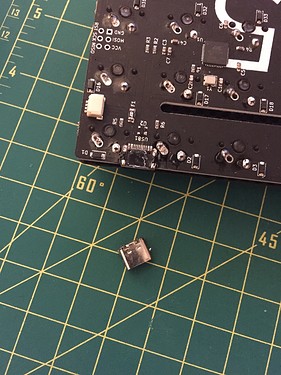

Made a rookie mistake and borked the USB connector on my Plexus. Despite knowing better, I picked the board up and moved it around while it was still plugged in. I haven’t been able to reattach the USB but mercifully the PCB has a JST connector… unfortunately I don’t have a case that is compatible with a daughterboard.

If anyone has a lead on a 60% case that accepts a daughterboard I would greatly appreciate it, otherwise this weekend I might have to break out the dremel and mutilate my tofu. I love typing on this board and the layout is perfect for me so somehow I will bring this bad boy back to life.

I feel like some of you might relate…

What’s the longest you’ve gone without realizing you accidentally swapped ;: and '" ?

months. I do the same with _- and +=

Ouch!

I believe that is technically repairable; you can order those USBC ports on their own, and then use loads of flux soldering it back on to keep the tiny contacts from bridging. Worth a shot, maybe!

Most of Louis Rossmann’s Mac repair videos involve him soldering components with lots of tiny leads like this, and he takes video of the process with a nice level of magnification.

If I understand the process correctly, you put a wad of flux covering the contacts you want to join, and then get a small-ish blob of solder on your iron. Have the port in place, maybe with a small clamp or clip, making sure flux is covering everything you want to join, and the spaces in between. Then, just drag the hot solder blob across them - theoretically, the solder should stick to the joints and be repelled from all the other surfaces by the flux.

Thanks! I’ll look into his process, though I fear with my soldering skills I’m just as likely to burn out some of the nearby components as I am to actually repair the port lol

By my calculation, about a week.