Update:

Got one of the birchwood plates installed into one of my Porticos, the currently-available 68 Black Label

More photos, notes, material caveats

It fits! Yay.

It also works, and is even pretty easy to install - I do recommend a plate fork if you aren’t using foam or something else below it, though.

Installing the switches carefully with the fork went well, with only a little de-lamination here and there, caused by the clip teeth. This went much better than the intentional torture test I did earlier, hastily installing tons of different switches in one of these:

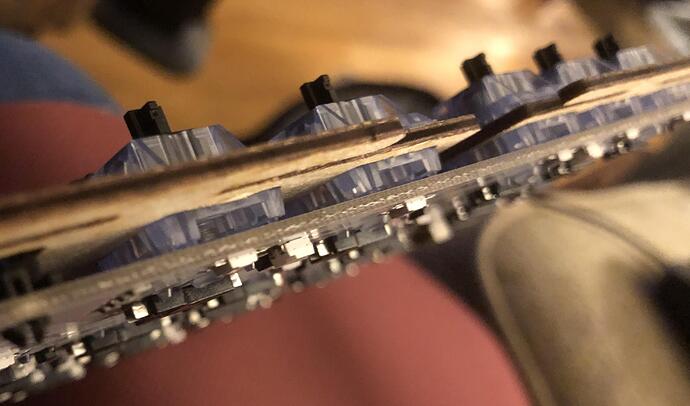

It’s actually quite easy to separate the layers accidentally:

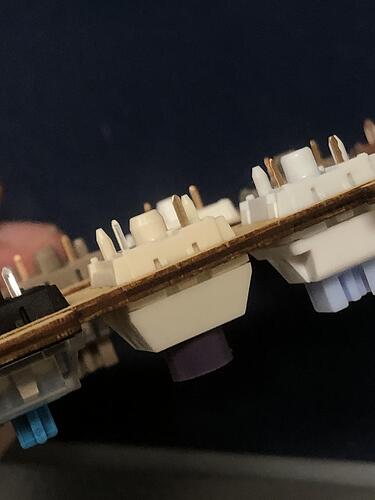

But, some switches do seem to get along better with the 1/16" plywood than others:

Those clips on the Kailh Box, for example, appear to function just as intended. That gave me some hope after how roughed-up that first plate was by the end of the torture test, and it did work after all. Using the fork went a long way in preserving the layer adhesion and integrity of the fibers.

So what’s it sound like? I think I might do some more recordings with this later with a few different switches and configurations, but for now here’s a quick and dirty comparison:

As a point of comparison, here is a Portico68 BL with all the foam installed, a flex-cut polycarb plate, NK_ Silk Olivias, and GMK CYL keycaps:

Now, here’s the same model keyboard with foam below but not above the PCB, the 3-ply birchwood plate, NuPhy Night Breeze linears (POK stems), and MTNU keycaps:

Edit: also… it smells good

Considering this was some of the cheapest 1/16" wood I could get without looking very hard, I find this result pretty encouraging. ![]() I’ll keep using this one for a while and see how it goes, and I also intend to continue experimenting with other materials.

I’ll keep using this one for a while and see how it goes, and I also intend to continue experimenting with other materials.