Here you go

Very nice! I see you are living in Germany. Where do you source that PCB from? I may also eager to lay my hand on this form factor…

Directly from purox, he had some spares and we organized a group order ![]() First way to go otherwise would be JLC imho, alternatively you can also order at Aisler but with higher price/PCB but local manufacturing

First way to go otherwise would be JLC imho, alternatively you can also order at Aisler but with higher price/PCB but local manufacturing

Sorry, I need to ask more. What do you call such keyboard layouts in general? Batwings?

What would be the place to be to get informed on other such designs? Perhaps you should open here a dedicated thread for these keyboards.

The thing is, I am looking for a design for use with ordinary keycaps to try out.

I think you’re referring to Katana layout? Sure I can create a catchall for that ![]()

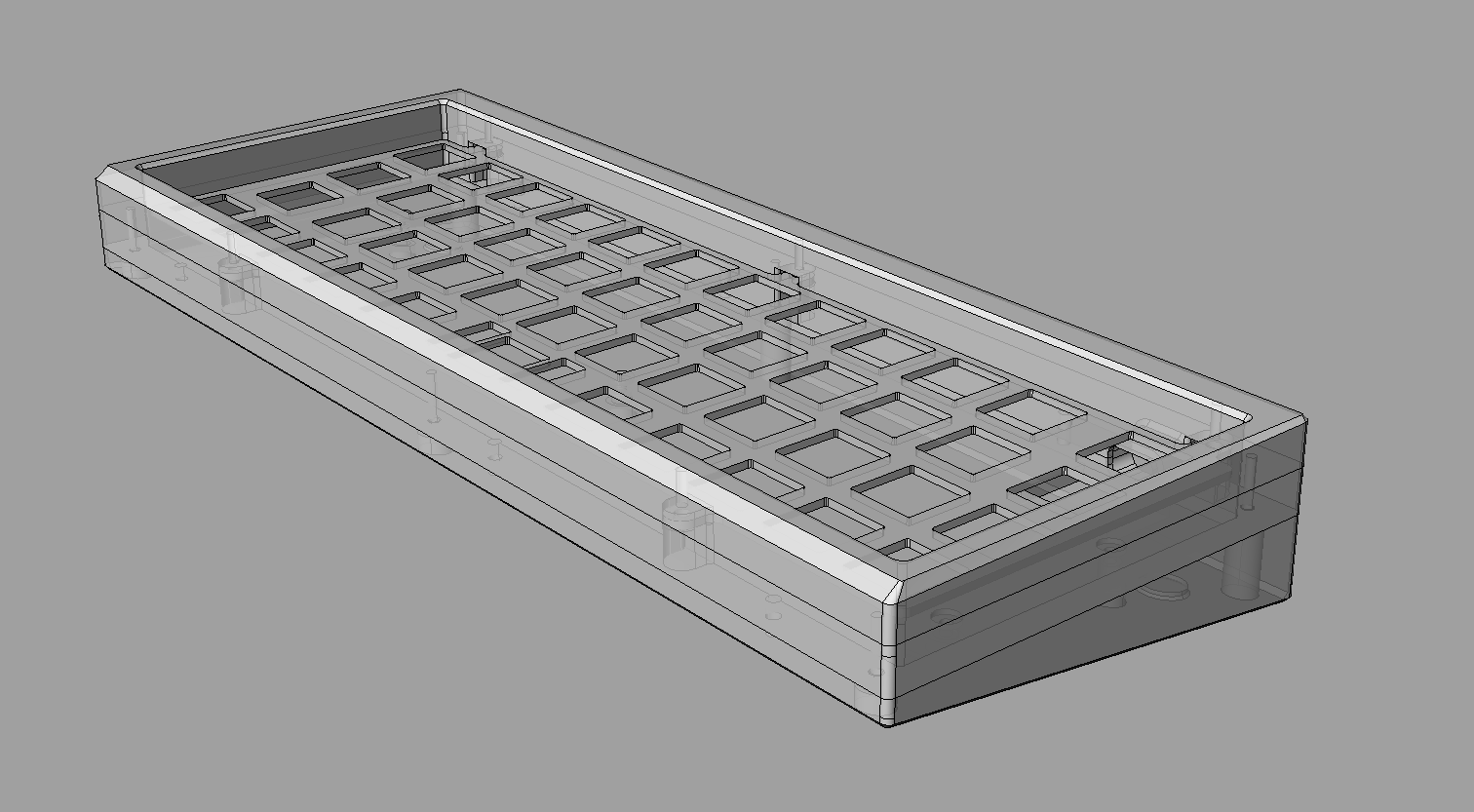

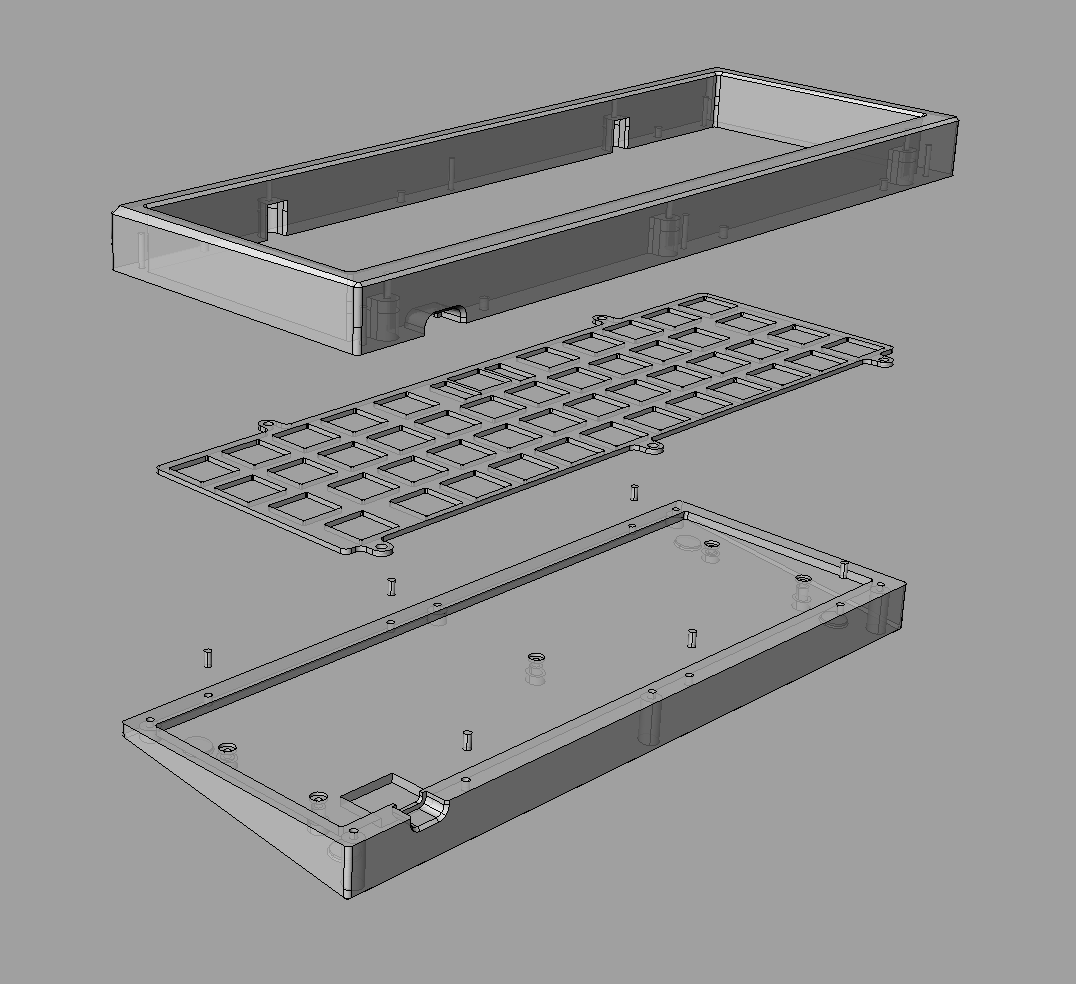

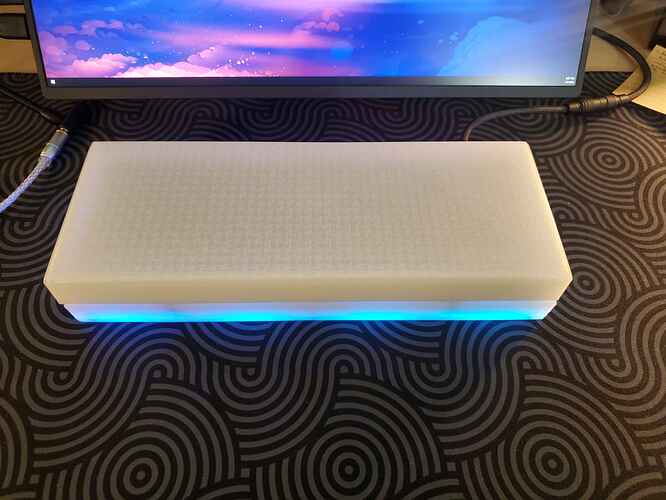

Designed and 3d printed a top mount case for the UT47.2. 7 degree typing angle and plate held in with #2x1/4 screws and some 6x2.8x1.6 orings. Top and bottom screwed together with #2x3/8 screws.

Boba u4tx and Kitty Kat keycaps.

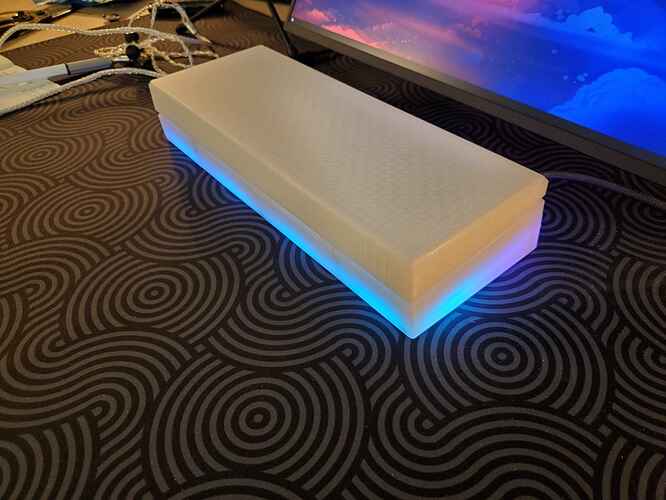

I used Kingroon transparent PLA which is kind of warm/hazy. Probably poor choice of material for seeing the actual case, but great for hiding FDM imperfections ![]() Printed on X1C with the smooth PEI plate so top and bottom surfaces are super smooth, 0.16 layer height.

Printed on X1C with the smooth PEI plate so top and bottom surfaces are super smooth, 0.16 layer height.

Well that came out really nice. I think you can print a planck on an Ender 3, so would the X1C have been just big enough to do the parts in one piece?

Also, I’m always curious about people’s CAD choices. What did you use and how do you like it?

Very tasteful design! Congrats.

I use Rhino because that’s what I learned back in architecture school, and I’ve not found the time or energy to learn something else like blender or fusion360. It’s good but has its limitations when it comes to sculpting and more freeform design that’s advantageous to 3d printing. IMO it’s a pretty rigid modeling/design flow (NURBS), but I’ve grown so accustomed to it for basic stuff (no crazy curvaceous stuff) that it’s just natural to me now.

The X1C is just big enough to print the parts at a 45 degree angel flat on the bed. Wish it was big enough for 60%s lol, and I’ve yet to figure out optimal supports to print at an angle without horrible surface finishes or insane print times.

Thanks! I often wish I knew how to machine metal, or have a friend who does loll

I recently bought a copy of Alibre Design because it’s a permanent license for about as much as a year and a half of Fusion. My English and law degrees did not exactly expose me to a lot of mechanical design software, but I can read a License agreement like a mofo. ![]()

I hear good things about Rhino though, both as an app and a company, and the Grasshopper plugin can supposedly be used to do some of the things that a parametric history tree can be used for in Fusion, etc. You wouldn’t want to use Blender anyway, if you want to do subtractive CAM (e.g. sending out for CNC milling).

I want so much for FreeCAD to become the Blender of the mech CAD world, but while they’re closing in a big milestone (version 1.0), it’s still got a lot to sort out. I’m hoping it’ll be in a good place whenever I finally decide my Alibre version is too old.

I use Solidworks, but being in the CNC industry for 18 years thats one of the bigger CAD options.

Solidworks is still the mid-market king, right? Their hobbyist subscription is pretty tempting, very cheap and allows for a few sales without violating the terms of use (looking at YOU, onshape!). If a project were to get some traction, though, that could get expensive, assuming one wanted to stay in full compliance. ![]()

Haha sounds like you’ve done your research. It’s true, I’ve only heard good things about Bob McNeel.

I feel like an old dog with brainrot nowadays. Hard to learn new software. Honestly it’s just a tool to me and I can get by with what I need with Rhino thus far. Maybe one day, in another life ![]()

Open source software is always the answer!

…more so, if you use GNU/Linux exclusively like I do.![]()

Open source software is always the answer!

…more so, if you use GNU/Linux exclusively like I do.

Oh, I tried, and I keep up with them. Realthunder’s Toponaming fix should be more or less sorted by the end of the year, and the Ondsel money (until it runs out because their business model is insane) is helping with UI and assembly, but it’s still got so very many workbenches, such awkward flows, and it crashes in the weirdest ways. I finally threw in the towel when it persistently crashed on both Linux and Windows just trying to import a DXF in as a draft and then a sketch. I will always have it installed, though, especially on my linux partitions.

Alibre has a few quirks, but it mostly just works and they’re not a 500-pound gorilla in the space, which left me feeling less guilty. I don’t spend a lot on the keyboards themselves, but I do like having tools I enjoy using. I was actually using a very cheap package I got for 20 Euros off a low-end “boomer-ware” site in Germany, called BeckerCAD. It’s surprisingly functional, but has no parametric history, compatibility limitations, and a weird workflow firmly rooted in 2D (which I still use it for).

Im not entirely sure. I have a full copy, but I know some of our bigger customers that use it(think space and such).

Printed a wrist rest for this chonky case. Has a cavity so it can fit over the keys for travel. Maybe I’ll just use rubber bands or something to hold em together.

This wrist rest printed so smoothly it’s pristine. I’m annoyed my other parts aren’t this straight and smooth.

EDIT: Updating pictures

The Bambu X1C is so freakin cool lol

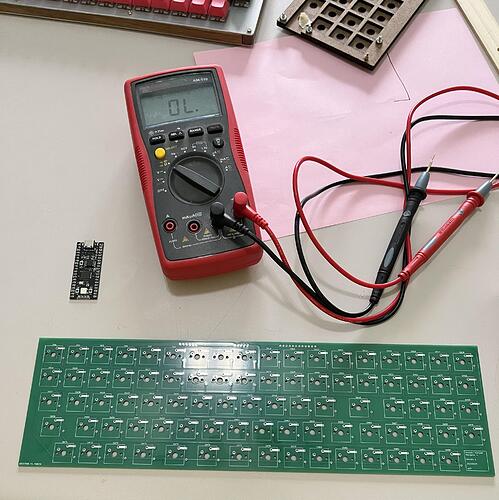

So my Fisher Price My First Circuit Board arrived from JLCPCB. Intellectually, I know there was precious little to mess up in such a simple design, but it was still deeply satisfying when the matrix checked out.

Case has been designed (v1 at least; still noodling a couple of ease of assembly verse rigidity concerns), plates laid out, and the RP2040 is set to go as a “daughterboard.” Time to have the laser and printer start earning their keep.

proudly designed in China

… that’s a first. Interesting.