Build #16: Beach Norbatouch

This is a long one. Go grab a nice beverage before you settle in.

From the moment I saw the Norbatouch case with the Retro Refrigerator finish, I had a vision for it. While the name for the finish suggests an appeal to fifties-era Better Homes and Gardens nostalgia, the actual color suggested something else to me - the color of a beach bungalow, the kind you might see along certain Florida coastlines or a Caribbean island. That particular coastal colorway implies white and beige tones, and maybe the color of a bungalow’s weathered sun deck, all colors which I thought would combine to yield a really nice looking board.

While I had the vision, what I didn’t have was, well, any of the parts. Ha!

Sourcing the materials

Let’s start with the proper donor board. Sure, we can still use the relatively-easy-to-find CoolerMaster MasterKeys Pro S with the Norbatouch, but I wanted this first Norbatouch to serve as my introduction to Topre, which meant getting my hands on a Novatouch TKL. The Novatouch, a CoolerMaster board with MX-compatible Topre sliders, was discontinued in 2016, and they have since become steadily harder to find and more expensive, as the infamous purple sliders are generally regarded as the cream of the available crop for putting MX-compatible keycaps on a Topre board. Here, let @Manofinterests school you.

Still, with sufficient devotion, the ebay gods will eventually smile upon you, and I recently found myself in possession of a heavily used but functional Novatouch. As advertised by the seller, there was one problem; the MX cruciform for the slider on the ESC key was broken. I figured I could deal with that by using a KBDfans MX slider to replace the broken one, and moving it to Scroll Lock, an essentially unused key.

Next: keycaps. Readers of my build logs may recall the problems I had with finding color-matched keycaps in the wooden case Zilent series of builds. I wanted to avoid that problem this time around, so one of the first things I did, months before I had either the case or the donor board, was to obtain color chips for the DSA dye-sub sets offered by PMK, for all of the colors in the dye-sub offerings that could conceivably work for the colorway I was after.

While I didn’t find exactly what I had in mind, I did find three colors among this set that appeared close enough to work, and picked up the necessary sets for TKL coverage. DSA isn’t my first choice for profile, but I really wanted to get the colors in the ballpark, and felt I could do that with these caps.

Finally, the case itself. I’ve had a Norbatouch Pi in Retro Refrigerator on order for a while, but I couldn’t resist the opportunity to pick up a recent R2.5 extra in this finish to finally get this build underway (teaser: I now have alternate plans for the Pi - drop by in a few months…)

Pre-build evaluation

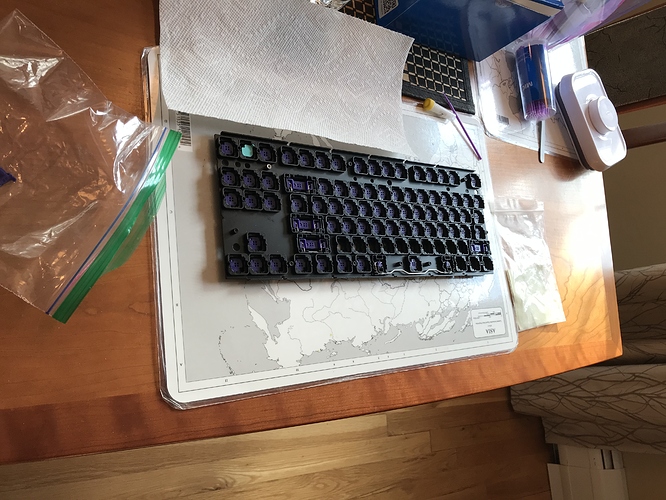

We’re starting with a used Novatouch as the core of this build. It’s worth evaluating the exterior and interior of the keyboard to see what else we might need to do before treating it to the full Norb. Exterior first.

- As disclosed by the seller, the cruciform of the ESC slider is broken, and there isn’t any way I can see to make it usable again. But that was expected, and as mentioned earlier, we should be able to replace it with a workable alternative.

- This keyboard rattles like hell. Although the stabilized keys are worse, most of the 1u keys rattle too. Either this board has really seen little love by its prior owner, or the owner was willing to put up with a lot to get Topre action with MX sliders, or perhaps both. It’s kind of like typing on nice rubber domes through a plastic bag full of cheap silverware. Unusable.

Before we take a look at the interior, put on your hazmat suit.

I mean, OK, it’s used. We expect some crud. But this seems excessive?

Also some gunk on the sliders, and on the domes, so, before this even gets near a pristine Norbatouch case, we have a refurbishing project on our hands.

- Completely dismantle the Novatouch to get at all parts for cleaning.

- Remove all solid matter from the plate with isopropyl alcohol.

- Clean the domes lightly with soapy water, and let air-dry thoroughly.

- Clean the sliders with soapy water, and let air-dry thoroughly.

Then, and only then, can this board go to rehab:

- Install silencing rings on sliders.

- Lube rails of slider housings.

- Lube stabilizer sliders, clips, and wires.

- Reassemble plate/domes/PCB sandwich and evaluate.

On the other hand…nothing to desolder! Always look on the bright side of life.

Refurbishing a Novatouch

First, we have to get into the case. There are four screws to remove. Two are in the obvious locations:

The other two are hidden underneath stickers on the case. One is under the “DO NOT REMOVE” sticker, and the other is hidden under the serial and model number sticker.

Once those screws are removed, the top piece of the plastic case can be separated from the bottom by working a credit card around the edge and gently prying to release the tabs holding the case together.

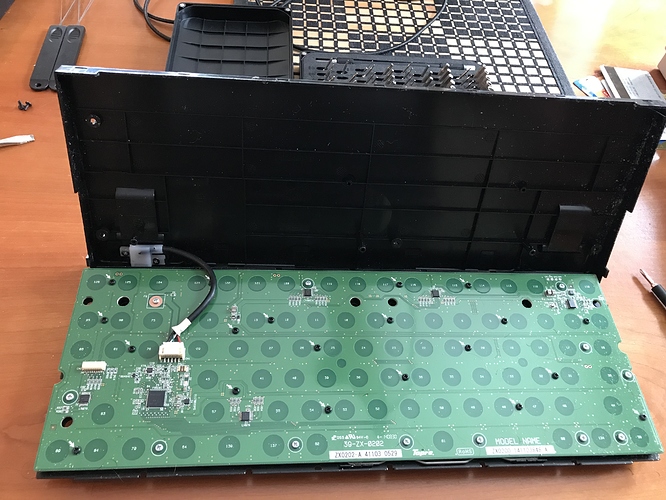

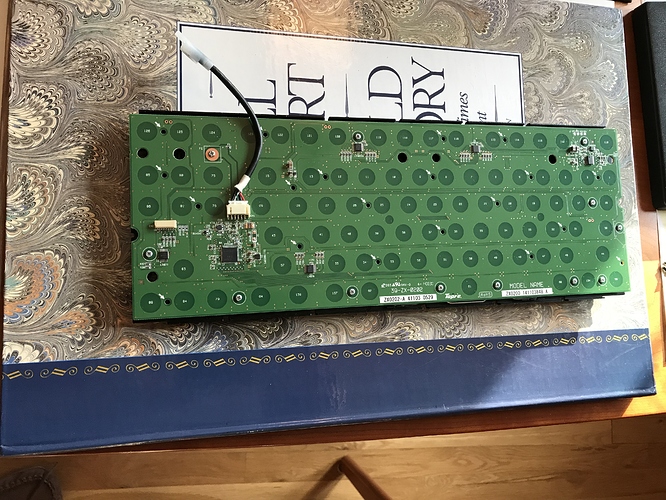

Be careful when removing the PCB/plate assembly - it’s connected by a cable to a USB housing attached to the bottom half of the case.

That housing is held to the bottom half of the case by two screws, and can easily be removed.

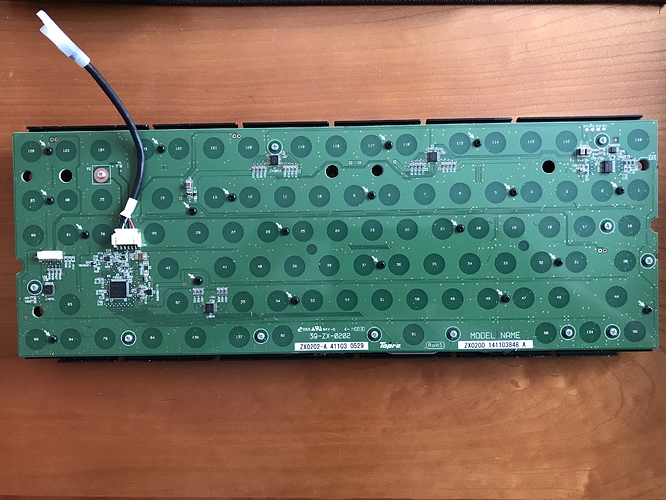

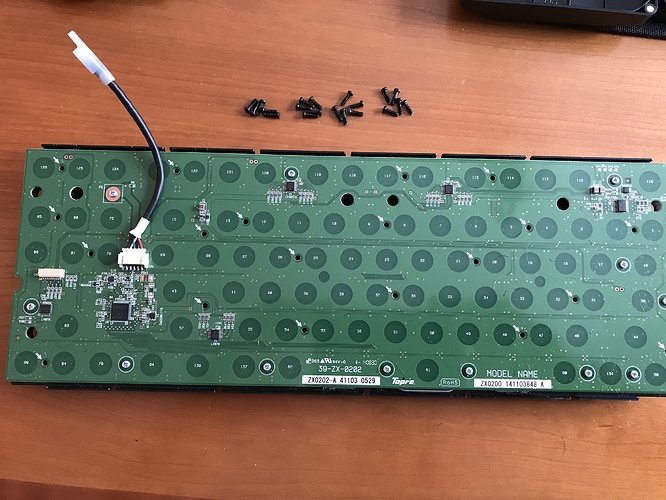

Now, look at that last photo, at all of the little white arrows on the PCB, pointing to black screws. There are 20 of those. You have to remove all of them. Yes, all of them.

Did you think you were done? Not just yet. See the silver-headed screws, marked on the PCB by white circles, and the one with a red ring and white square, 12 in total? That’s right, all of those have to be removed too.

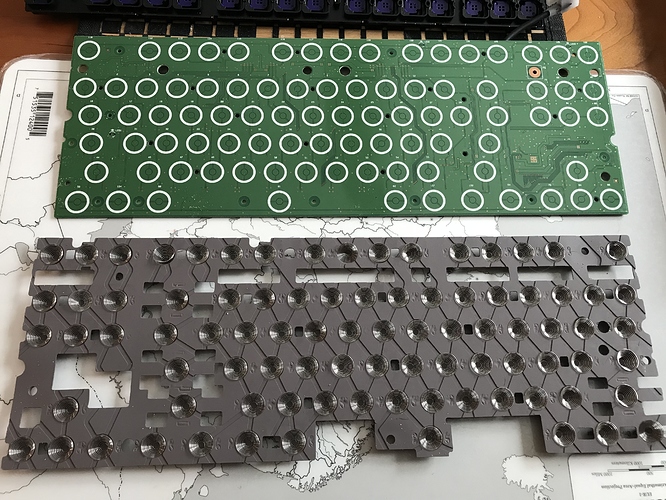

Once you’ve removed all of those, there is no longer anything holding the rubber domes and springs in place other than pressure, so you now need to exercise care in separating components, so that you don’t launch those delicate conical springs everywhere. Starting from the photo above, and holding both sides of the PCB/plate sandwich tightly together, I inverted the sandwich and set it down on the table, and then gently separated the plate/slider assembly from the rubber dome and PCB layers of the sandwich. In the top half of the following photo, we see the tops of the rubber domes, which are part of a rubber sheet sitting atop the springs (which you can’t yet see), which in turn sit atop the PCB. In the lower half of the photo, we see the inverted plate/slider assembly, which also gives us our first look at the stabilizer assemblies on the Novatouch.

At this point, we can take a peek at the springs. Note that the rubber dome sheet is quite thin, and I felt it would be easy to tear some of the sheet’s thinner struts, so I was quite gentle when handling it.

We can also see what happens when a rubber dome is pressed directly.

After getting those photos for your benefit, I washed my hands thoroughly. Did you notice all of the residue on the membrane and PCB? Ugh.

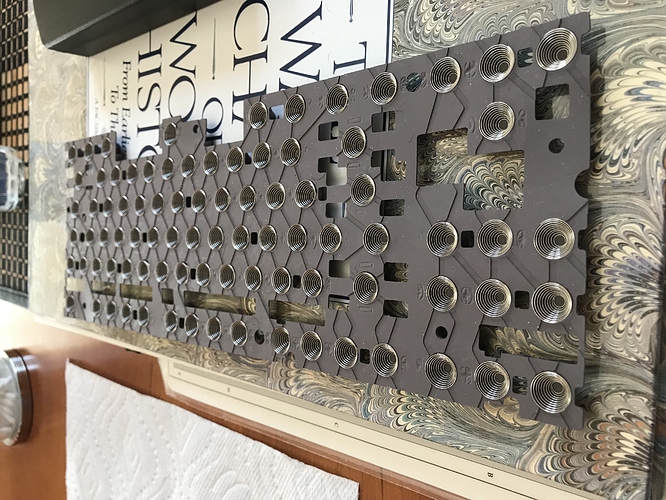

I sandwiched the PCB/dome assembly between a couple of placemats and flipped it over, and then gently lifted the PCB away from the rubber membrane, giving us our first look at all of the springs, and the other side of the PCB. Note that the springs simply sit atop the PCB, on the white rings, and the rubber dome sheet lies across the top of all that; it’s held together by pressure and those 32 screws we removed earlier.

At this point, it’s time to start cleaning. After reviewing a bunch of online resources on Novatouch disassembly and cleaning, I elected to use cotton swabs and isopropyl alcohol to clean the plate.

Here’s the result after the first pass:

After the second pass:

I also wanted to clean the sliders, which had cruft inside the cruciform stems, and underneath, inside the slider housings. Removing these is pretty easy - I just used a fat hex head on a screwdriver to apply gentle pressure to the cruciform stems from the top of the plate, to pop the sliders out the back of the plate.

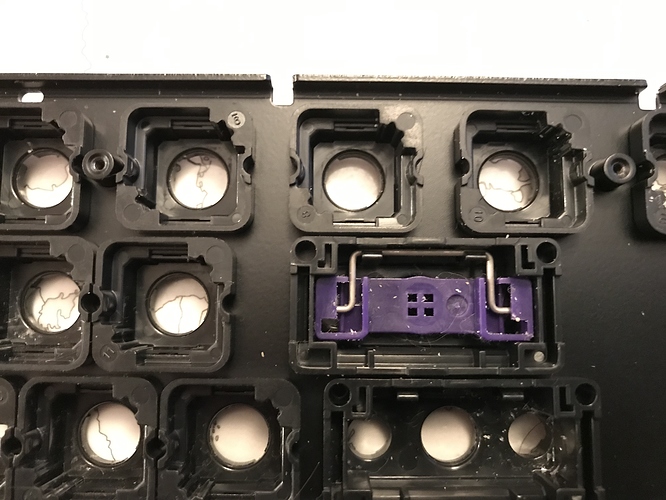

To get the sliders for the stabilized keys out, it’s first necessary to pop the wire out of the clips that hold it in place. Here’s a closer look at the stabilizer for RShift.

To clean the sliders, I used warm soapy water and more cotton swabs. Note that I’ve taken the opportunity at this stage to discard the one broken slider and replace it with a KBDfans slider. Which of these things is not like the others?

We’re still not done cleaning. As you may have noticed, the top side of the membrane had cruft on it as well, and I felt it was best to remove the springs at this point so that I could gently clean and air-dry the membrane. More warm soapy water and cotton swabs.

Mods and reassembly

With the cleaning task complete for the plate, the sliders, and the rubber dome membrane, it’s time to start improving the performance. First up, we need to lube the sliders. Or, more accurately, we need to lube the housings. Many of the guides online discuss lubing the sliders, but if you play with a slider in its housing for a bit, you’ll see that most of the slider does not actually make contact with anything. Movement occurs along the ribbed rails at opposite corners of the housing. I applied 3204 to both rails of each housing, and a little dab at the base of each rail where the sliders would impact on top out.

In addition to lubing, I applied silencing rings to each slider. The KBDfans silencing rings are very thin rings that sit at the base of each slider and absorb the impact when the slider returns from a keypress and hits the housing. These rings are made of a thin, rubbery, almost gelatinous film, which makes them a hassle to apply. Again, tweezers are your friends - I used them to work each ring down the stem of the slider, and then to flatten them out at the base of the slider. Here’s a close up of an installed silencing ring (the black ring at the base of the slider stem).

I did have an issue with one key on the first time around - the ring didn’t seat correctly, leading to an annoying click on the keypress. Unfortunately, this meant taking the PCB/plate sandwich back apart to pop out the slider and apply a new ring. So it goes.

Next up, reinstalling the sliders and stabilizers. This is straightforward and quick. For the stabilizers, I liberally applied SuperLube to the wires and the clips where the wires mount, as well as inside the stabilizer sliders where the wires make contact. This took a couple more passes before I felt comfortable that the result wasn’t going to rattle. FWIW, I used quite a bit more SuperLube on these stabs than I would typically use on an MX build - they needed it.

Next, we have to get all of the springs back in place in the rubber sheet, which is a chore. The springs have to be placed cleanly in each rubber dome, level with the membrane and PCB, and aligned correctly in each dome. If a spring is even a little bit off with respect to its ring on the PCB, it will not register a keypress. Adding to the fun, the springs themselves are also quite light and delicate. I found tweezers to be invaluable for this task - both for carefully picking up and placing springs in domes, and for leveling the springs, by laying the tweezers sideways across the widest ring of the spring and applying gentle pressure to seat the spring in the dome.

We’re now ready to put the PCB back together with the springs and rubber domes. I did this by carefully aligning the PCB screw holes with the holes in the rubber membrane, and very gently lowering the PCB into position. Again, I have to stress that level springs and PCB alignment are critical here - the second time I did this and put everything back together, the Tab key was unresponsive, and after disassembling, I found that the spring for the Tab key was a fraction of a millimeter out of place.

If the alignment is good, you’ve now got 32 screws to put back in place. It’s worth noting that all of those screws serve a purpose - they help to ensure that the sandwich is evenly compressed enough that the springs are held exactly in the correct position to generate capacitance on the PCB rings on keypresses. Don’t lose them!

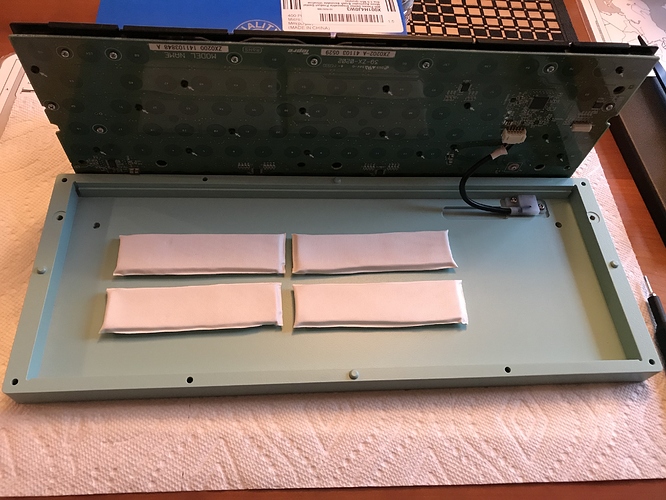

Next up, case dampening. You know how I roll - it’s Sorbothane time. I started with a 0.1" thick sheet of Sorbothane, and cut eight strips of equal size.

Why this many strips? Because 0.1" was not thick enough to span the distance between the case base and the underside of the PCB. By stacking pairs of strips, I obtained enough thickness to make contact with both surfaces.

Next, I reused a technique I’ve been using recently to make it easier to work with Sorbothane without the stickiness, and to avoid any potential case-staining issues with Sorbothane plasticizers. I placed the stacked Sorbo strips on a piece of gaffer tape:

Folding the tape back over the stack, pinching the tape together to form a packet, and trimming the excess tape away, I obtain a Sorbothane packet, ready for placement in the case.

The original eight strips yielded four 0.2" thick packets, which I felt would be more than enough to get good sound results without having to fuss over placement. Here, I placed them to avoid the USB connector and wire, which has already been attached to its new home in the Norbatouch case.

Getting closer to completion! The PCB/plate assembly is mounted in place by two screws on the perimeter of the Norbatouch base; here’s one of them, the silver hex screw. As @norbauer himself mentions later below in the comments, these screws are not necessarily intended to bring the plate flush with the housing, but in this particular build, with the Sorbothane packets underneath the PCB, the screws are useful for dialing in a good level of PCB/Sorbothane contact and compression. YMMV.

The two halves of the Norbatouch are then screwed together via eight screw holes in the underside of the case. The two tiny holes in the upper left are the screw holes for the USB connector, and the two larger holes in the upper left and right are for the optional feet.

Before we install the keycaps and head to the beach, a bit of review…

Resources for Topre, Novatouch, and Norbatouch

This was my first non-MX build, and a large part of this project involved scouring the web for build guides and resources. Here’s the complete list of reference materials that I used for this project, in the hopes that having it all in one place might save someone else some time.

- Topre overview

- Ripster CM Novatouch Review

- Ripster chemical tests

- Wodan Norbatouch install

- TopClack Norbaforce build

- Cleaning a Realforce 105UB

- SuperLube can damage Topre domes

- BKE Redux replacement tutorial

- Where to lube Topre housings

- ManOfInterests slider showdown

- HHKB cleaning

- Cleaning keycaps with denture tabs

- Installing KeyClack silencing rings

- Stock vs BKE vs Redux domes

- Realforce disassembly video

- Jetski’s Novatouch Silencing Guide

Lessons learned

- It’s very much worth reviewing all of those guides above before setting out on the Norbatouch journey. By the time I had absorbed all of that material, I felt that I pretty much knew what the project was going to involve, and that more or less turned out to be the case.

- Lubing is absolutely essential, and the difference in sound is extreme. Before lubing, the keys rattled, and the stabilized keys were unusable. After, the keys just glide without a hint of rattle. Coupled with the case dampening, the keyboard produces a lovely satisfying thock. It’s glorious. Certainly the most dramatic before-and-after, soundwise, that I’ve experienced with any build to date.

- There is no need to apply lube to the sliders themselves - it’s enough to apply it to the housing rails, as this is where all of the slider contact happens. This makes for a relatively quick and easy lube job.

- The one KBDfans slider in this build is a bit looser than the native purple sliders. If I was building a board full of the KBDfans sliders, I might consider lubing the slider cylinder as well.

- Case dampening will also make a big difference - the Norbatouch is a big metal slab with significant space between the PCB and the case, so echo and reverb will be apparent without some kind of dampening treatment.

- Tweezers are always handy for any build, but they were especially helpful here for working with the springs and installing silencing rings on sliders.

- Rubber dome/spring/PCB alignment is temperamental. I would suggest allowing yourself time for at least 2-3 assembly/disassembly cycles. I actually got the placement right the first time, but I had to reopen the case to correct a faulty silencing ring, and during that process, I shifted a spring just enough that a key didn’t work after reassembly, necessitating another disassembly/reassembly cycle. All those screws! Welcome to Topre.

- Before cleaning any board, it’s always a good idea to check the solvents you plan to use and be sure they won’t react with any materials. Again, there is good information in the resources above.

- Cleaning used boards is a hassle, but there’s no avoiding it - not only for basic hygiene, but in particular to provide clean surfaces for lubing, and for slider silencing rings.

- Given the number of screws that have to be removed, I’d strongly recommend testing the board after you put in the initial 12 screws, but before you put in the remaining 20, and I’d strongly recommend testing again before you install the board in the case. If a lot of keys aren’t responding after the first 12 screws, it’s likely there is a big alignment problem that isn’t going to go away after the remaining 20 are installed. Domes and springs are finicky.

- On a related note, check every single spring and make sure it is seated properly in each dome before putting the PCB back in place. Every. Single. Spring.

- I didn’t mention it during the build log, but the Hasu USB controller works well for turning this into a QMK-compatible board. It helps to think of it as translating the native keycodes from the board to whatever keycodes you desire from QMK.

- It would be interesting to build a Norbatouch with a MasterKeys Pro S donor board, with heavier V1 Zilents or lighter V2 Zilents, to do a side-by-side comparison. To a certain extent, the sound and feel here remind me of the Zilent builds in my earlier build logs.

- This is my first Norbauer build, and the hype is real. The powder coat finish is gorgeous and smooth, and the rounded bevels on the corners are perfect. If I can find any faults here, it might be in the screw holes - all of them seemed a bit tight, even after reseating the screws and trying again. The riser feet don’t seem to want to screw in all the way, and I’m reluctant to apply heavy force for fear of scratching that beautiful finish, either on the case or the feet.

- I wish GMK offered an analogue to PMK’s DSA dye-sublimated options, for mixing and matching standard colorways with stock legends. I like the colors here, but really not all that happy with DSA after a few months of GMK under my fingers. YMMV.

Let’s wrap this up! Before…

…and after. Thanks, @norbauer!

Specifications

donor board: refurbished CoolerMaster Novatouch TKL

case: Norbatouch R2.5 (Retro Refrigerator finish)

case dampening: 0.1" 40 Duro Sorbothane, stacked to 0.2", wrapped with gaffer tape

PCB: donor

plate: donor

LEDs: none

switches: stock Topre

switch lubing: Tribosys 3204 on slider housing rails

keycaps: PMK DSA dye-sublimated

TKL Base (color: GQN)

TKL Icon Mods (colors: GEC, WAN)

stabilizers: donor

stabilizer mods: SuperLube applied to wires, sliders, and wire clip mounts

plate/PCB dampening: none

HxWxD (without feet or caps): 1.0"x14.63"x5.75"

HxWxD (without caps): 1.75"x14.63"x5.75"

HxWxD: 2.0"x14.63"x5.75"

assembled weight: 4.76 lb