I have been working on an aftermarket upgrade housing for the HHKB for well over two years. It’s by far and away the hardest technical challenge I’ve ever taken on: hence the name. But, after hundreds of hours in active research, prototyping, and testing (and nearly $40,000 in R&D costs), I’m happy to report that I’m just weeks away from a group buy. The injection mold for the switch plate is nearing completion, and I’m just waiting on that so I can shoot some typing tests.

UPDATE: The Heavy Grail is a real thing now; visit the group buy page!

My philosophy for the project

I’ve had many forks in the road on this project where I could have chosen the easy and affordable way to solve certain technical problems. To those who follow my work, however, it’ll come as no surprise that at every turn I’ve always taken the other path. My goal on this project has been to try to create the ultimate answer to the HHKB problem.

Key features

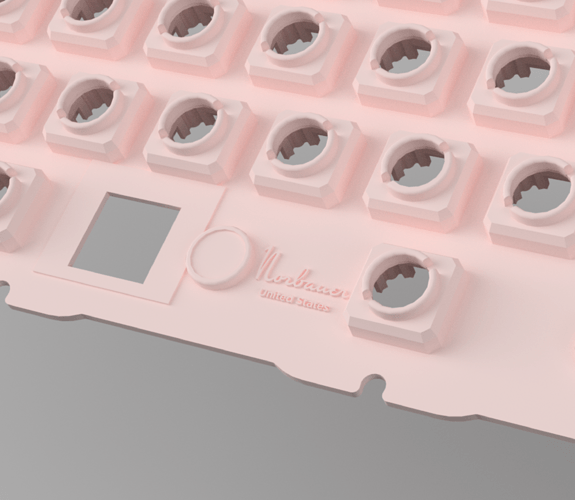

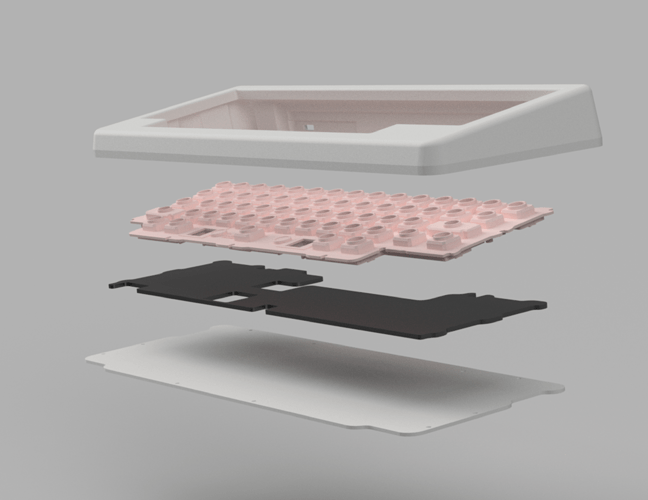

- A custom one-piece injection-molded switch/slider plate in ABS resin to replicate as best as possible the feel and sound of the original within a custom metal housing. You pop your sliders (and domes/coils) out of the stock HHKB and install them into my custom plate.

- Two versions: one for the HHKB Pro 2 and another for the HHKB Pro 3 HHKB models. (The “Classic” Pro 3 models work as normal, but note that if you use a PCB from a “Hybrid” model, you’ll giving up the battery/bluetooth functionality and will need to use it wired.)

- Acoustic dampener to minimize internal sound reflections, with clearance for internal electronics

- Full isolation mount to dampen vibrations at the junction between the polymer plate and metal housing, further replicating the bouncy feel of the original HHKB as best as is possible with a metal housing.

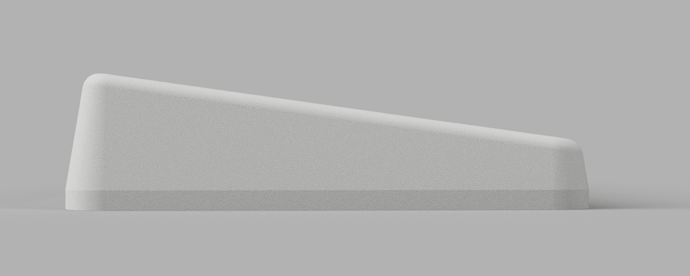

- Retro-futurist Norbauer-style tapered housing geometry (fusion between the Norbaforce and Heavy-6), the compound curves of which can only be cut on a 5-axis CNC mill.

- Heavy steel rear cover plate for weight and acoustics.

- Made entirely in the USA, down to the plastic in the plate and rubber in the bumpons. Most of the work happens locally here in Silicon Valley, California.

Cost will likely be around $650.

My technical approach

The philosophy articulated above is why I opted to create my own injection-molded plate, which is an admittedly quixotic and ambitious strategy.

The HHKB is an unusually technically challenging aftermarket housing to make for a Topre board because, unlike all other products I’ve made in the past, the plate from the OEM keyboard can’t be separated from the housing and removed, because on the HHKB they are a single inseparable piece of palstic. This requires re-making our own custom plate that as closely matches the original as possible (to give that characteristic dampened typing feel of the HHKB) while also being something that can be fit into a custom metal housing.

Previous attempts to solve the problem have tried to re-make the plate from milled aluminum, either fully milling all the slider housings (which is fantastically expensive and reportedly leads to a keyboard with gratingly awful acoustics), or using a metal plate with pop-in sliders harvested from another Topre keyboard, which doesn’t create the same dampened typing feel as the HHKB’s resin plate (and also requires a second sacrificial keyboard).

My plate is made in the USA in production steel tooling by a factory that specializes in ultra-precision medical parts. Working with a company with these capabilities proved the only way to get a super glossy finish on the intricate (and deeply recessed) slider rails, which my many experiments showed to be essential for a smooth typing experience (since those rails serve as a mating surface against which the sliders move).

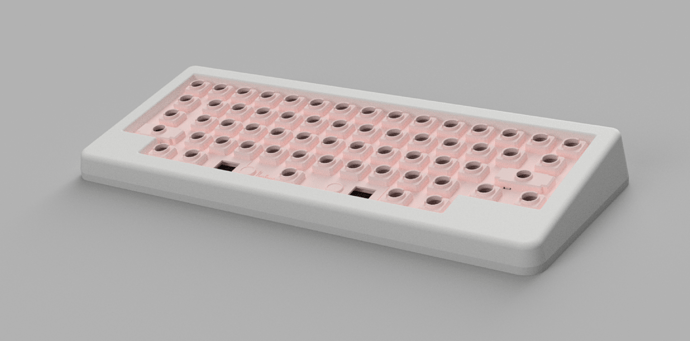

Below are some quick renders, simulating the housing in my K2 finish. (Alas, the plate won’t actually be pink–most likely white–but I thought it would be fun to render it this way and help it stand out against the housing)

Any and all thoughts and questions are welcome. ![]()