Hello keeb lovers,

Late last year I lurked again on various forums talking about mechanical keyboards and discovered that a lot had changed (in a good way) since I purchased my daily drivers around 8 years ago.

I’m a happy owner of two Filcos and a Topre Realforce and use them everyday but with so much beautiful custom keyboards in the wild I told myself that I had to own one ( at least ![]() )

)

Moreover the nice part of a hobby is to learn new things so why not design and build my own from scratch?

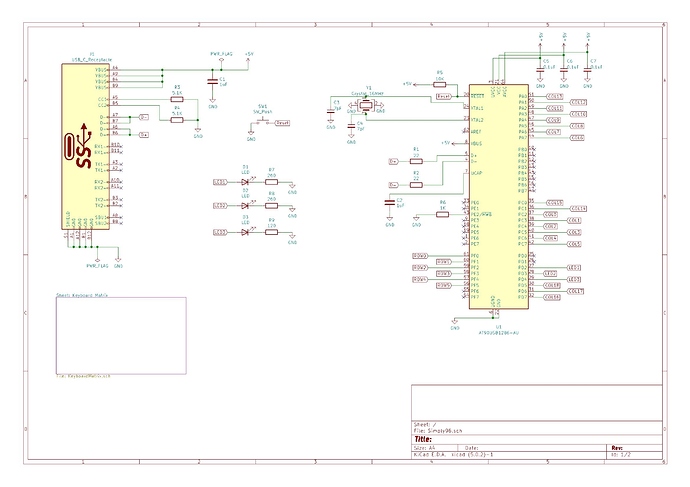

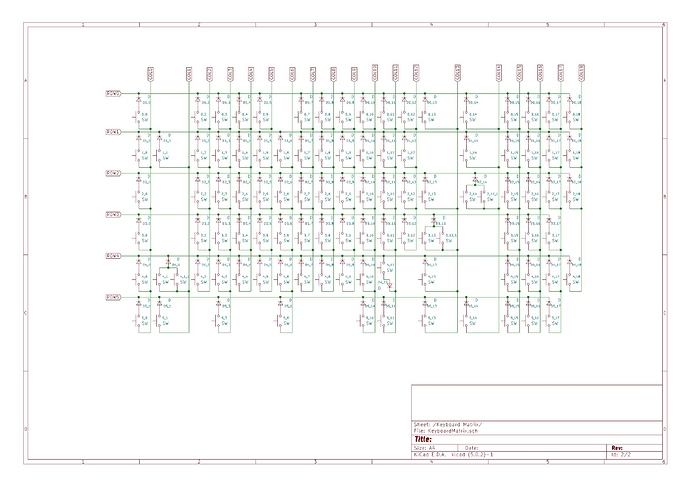

- Do my own PCB design (I do have some previous amateur experience)

- Do my own case design (I have no experience in CAD software and CNC manufacturing).

This will be fun ![]()

Most of the enthusiast keyboards out there have small layouts.

One benefit is that it removes arm strain during prolonged typing and mouse usage.

As a software programmer one caveat to me is the lack of some keys: function keys are used a lot in professional tools and even on my TKL the lack of a keypad impacts my productivity.

Still want something a bit more compact though as my arms are beginning to hurt a bit at the end of the day.

I have to say that I’m a conservative old fart ( you made my day when you called me “Uncle Rico” @pixelpusher ![]() ), breaking typing habits are getting difficult so learning new layouts being compact or worse ortholinear are out of the question: I want to use it at work and be productive very fast using it.

), breaking typing habits are getting difficult so learning new layouts being compact or worse ortholinear are out of the question: I want to use it at work and be productive very fast using it.

One accepted change is that, due to the lack of nice ISO/AZERTY keycaps, I will switch to US/ANSI layout.

I started some research to what would be the best keyboard layout for my usage and found that the TK layout was just perfect for me:

- It has a numpad.

- Much closer to a standard ANSI/ISO layout than a 1800 layout.

- Still significantly shorter than a full size keyboard.

Here are some links to known keyboards that used this layout already:

- http://www.coolermaster.com/peripheral/keyboards/tk-stealth/

- Plum 96 a brief review | TechPowerUp Forums

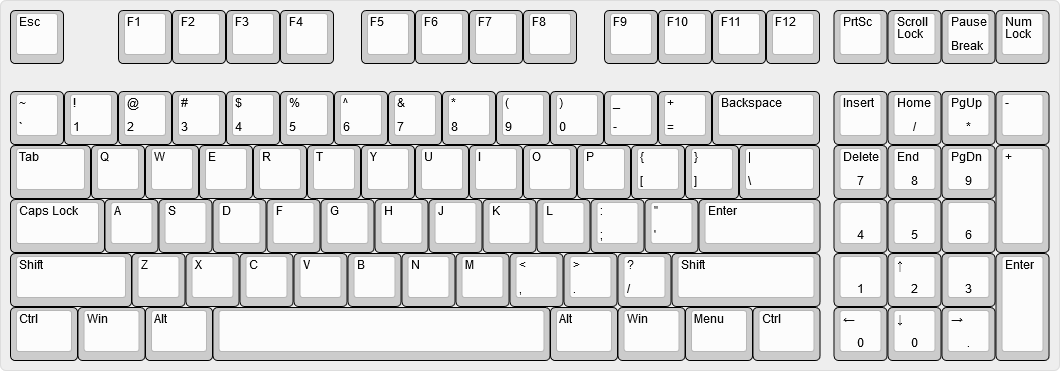

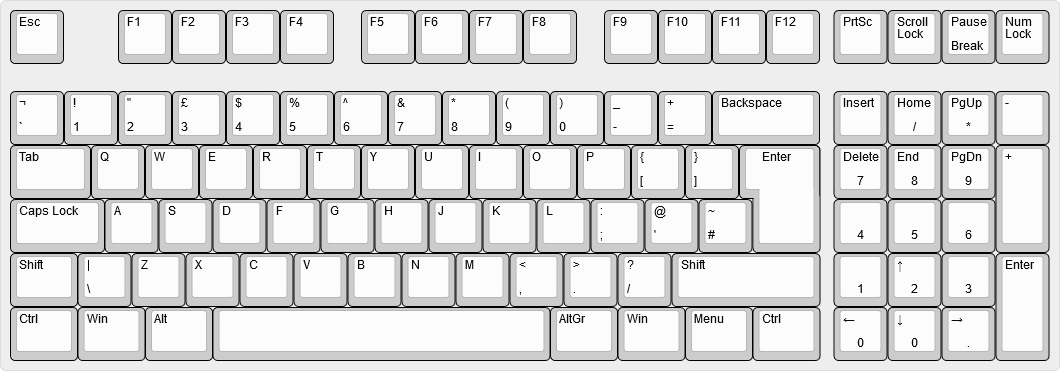

And also some KLE shots of the layout both in ANSI and ISO flavors:

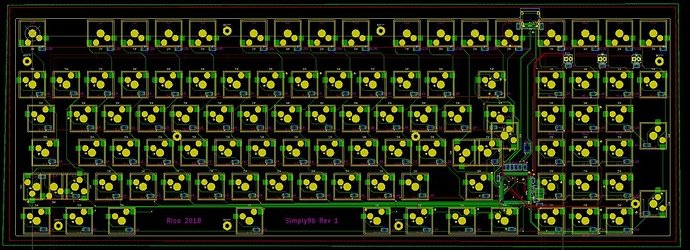

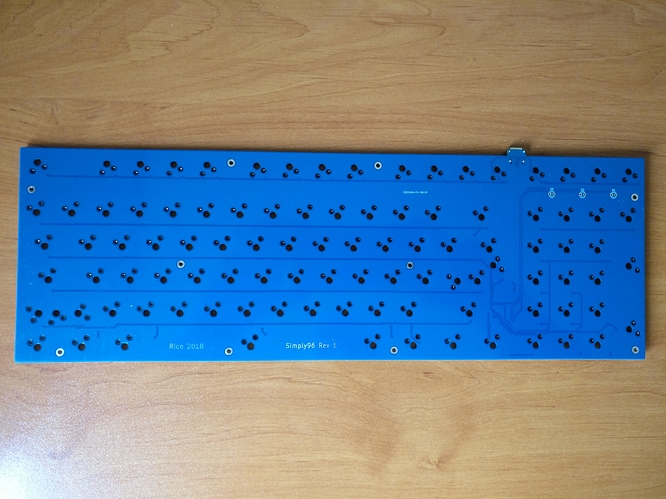

So development of the Simply96 keyboard started.

PCB and case designs are set and will probably not change unless I find a critical flaw that forces me to do that.

It is called Simply96 because it has exactly 96 keys in ANSI layout (97 in ISO) and it’s design is as simple as it can get:

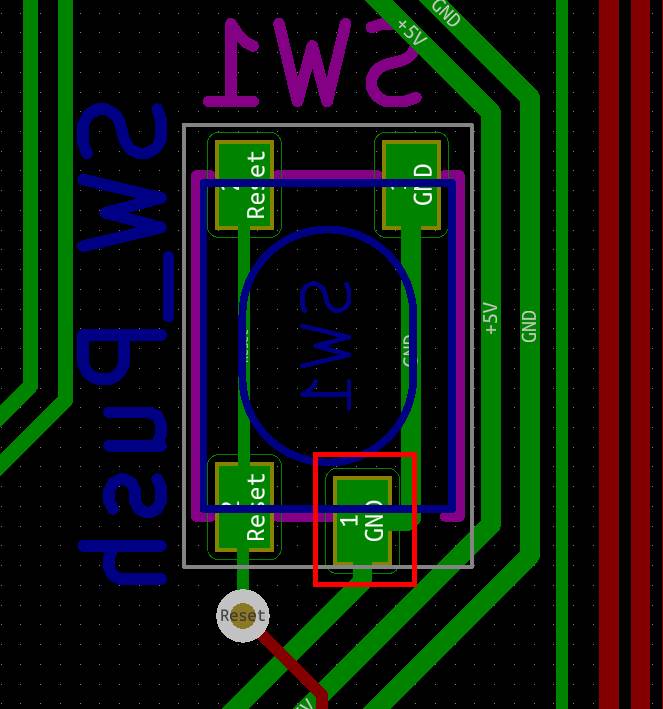

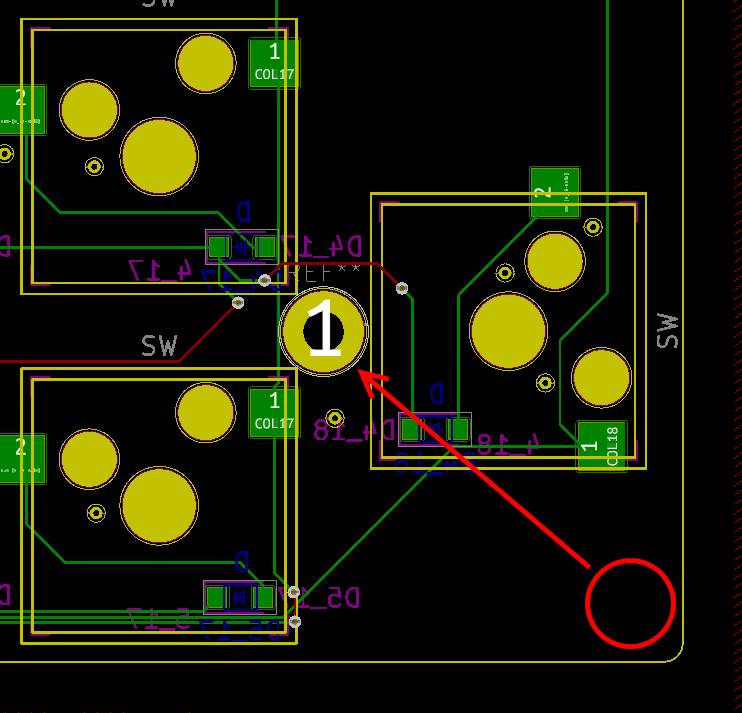

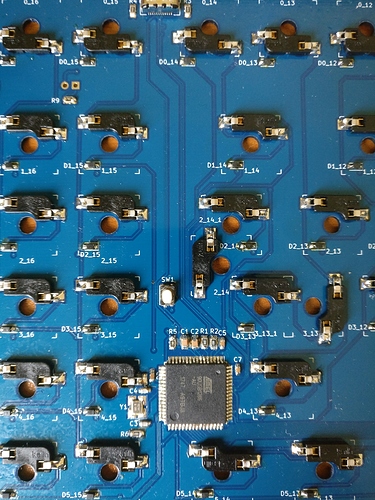

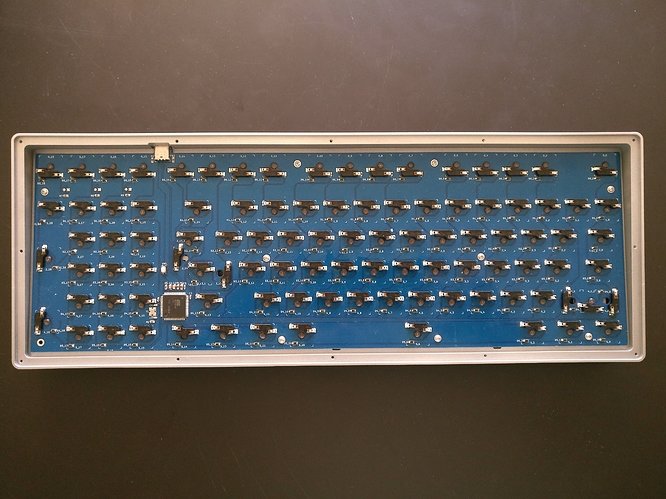

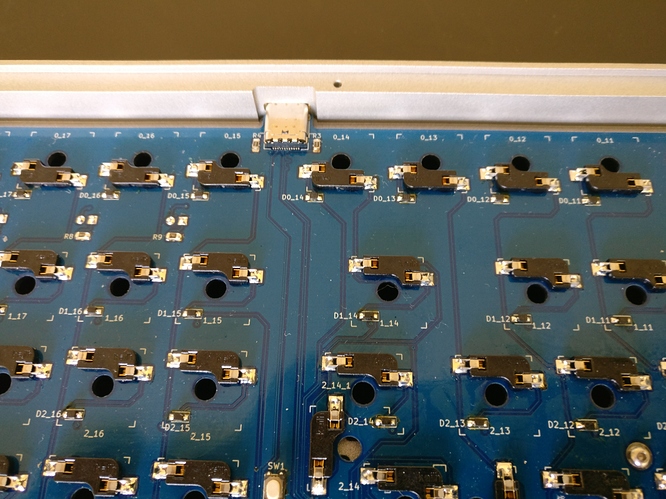

- Simplest PCB design possible with some features that I wanded to experiment with:

- QMK compatible: my daily job is programming stuff, don’t want to do that much during the weekend.

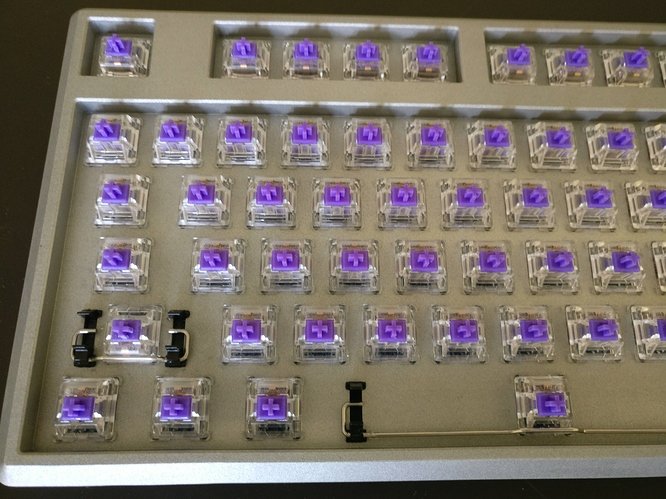

- Hot swappable using Kailh sockets.

- ANSI and ISO compatible(yes it’s possible with some constraints), only using ultra standard key sizes (6.25u spacebar only and so on).

- USB C connector: may not be “the future” but have always be cursed trying to plug all USB cables the wrong side the first time, sure it happens to everybody also

- No in-switch LEDs:

- Makes the design more complicated.

- Don’t see the use ( a keyboard is not a Christmas tree

).

). - Still could be added on later revisions.

- No RGB underglow for the same reasons.

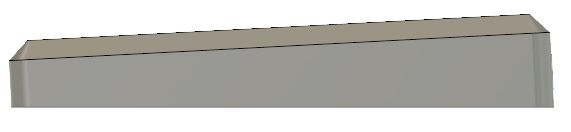

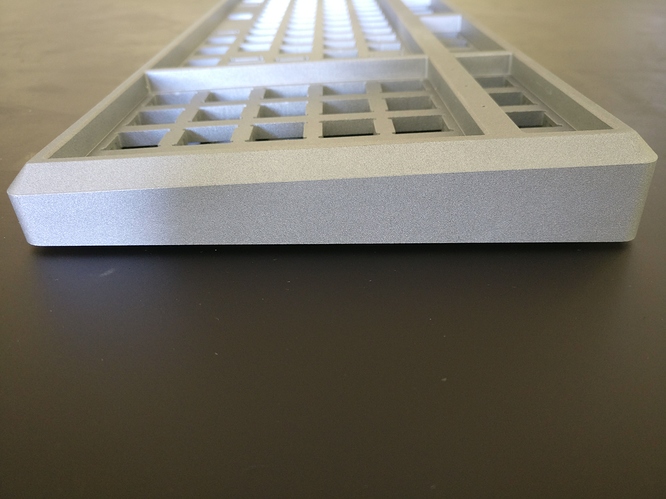

- Simple CAD case design:

- Because I’m learning Fusion 360.

- Doesn’t mean it will be awfull looking

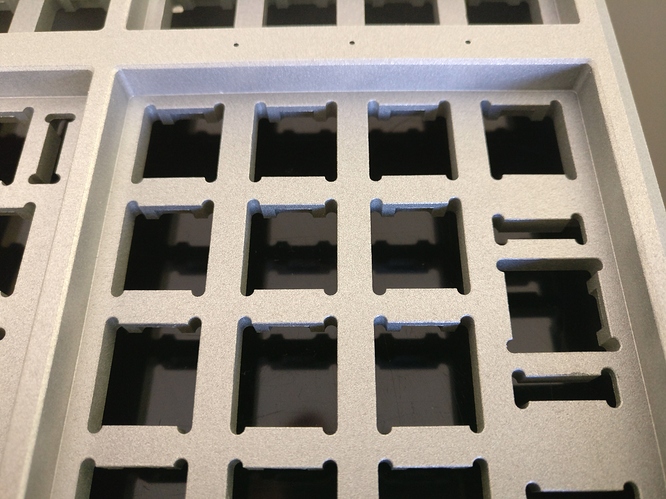

- Still it is an integrated plate design, ANSI only (for ISO I will need to make changes to the case design).

Here is a quick summary of the project status:

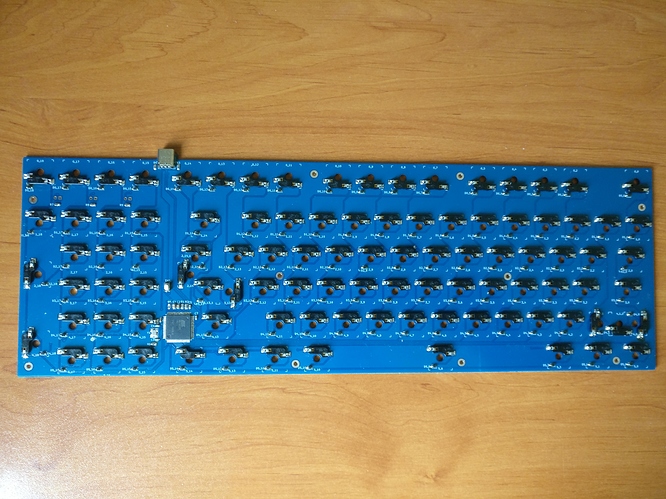

- One PCB prototype with an early QMK firmware working:

- I failed 3 boards and the fourth one went right.

- Pfff! only one spare PCB remaining

- Case design finished and sent to CNC manufacturing:

- This one is a BIG unknown as I’ve never done that before.

- I cross the fingers

Please note that this is NOT an interest check or a group buy proposal:

- It seems that this activity is very demanding and stressfull.

- I have a life, a wife and kids.

But if this works(for the moment it does not as I don’t have it on my desk), I may think of open source it.

For the interested people I will try to give regular updates on the project.

See ya folks!