Hello keeb lovers,

As a way to entertain myself and learn new things I started designing and making my own keyboards last year.

It has been a tiring and sometimes frustrating experience but I learned a lot in the process.

I now use my first homemade custom at work for nearly 6 months and I’m still surprised to find it better than my old Filcos and Topre boards.

It is my ‘precious’ ![]()

If you are curious, the history of the project is on this forum at this link:

I thought that this endeavour would discourage me to go further … just to discover that I was eager to start another design shortly after ![]()

Plus I jumped into the buying spree syndrom that most of you know, and ordered several keycap sets made by famous designers out there ![]()

I need to have a case prepared for these when they will arrive.

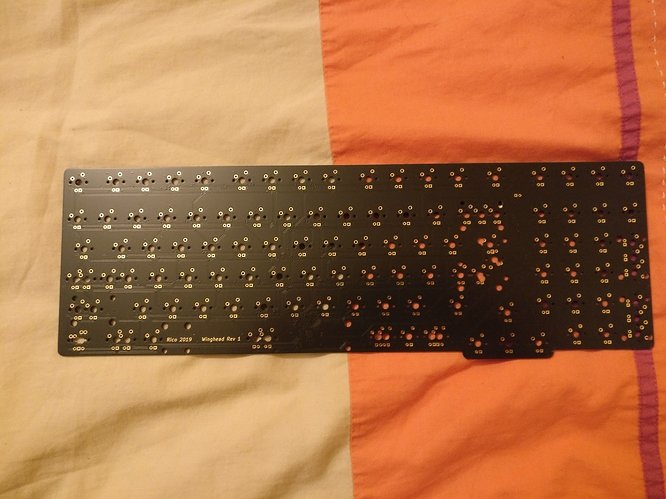

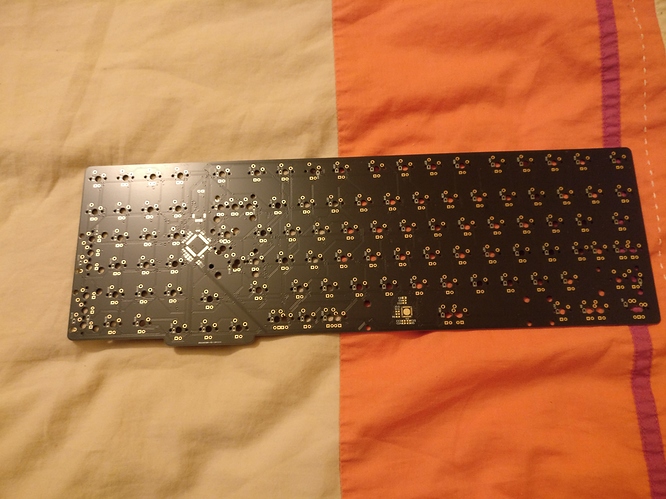

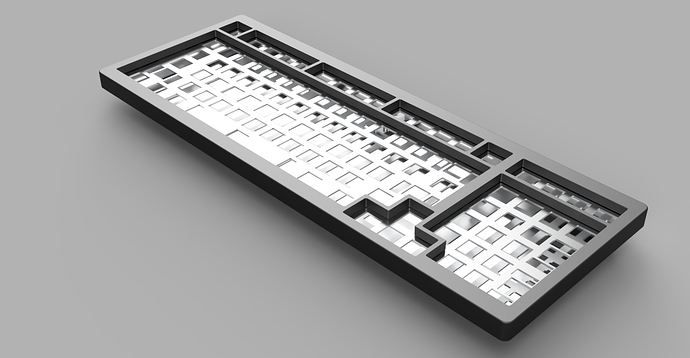

So here is my new project, the Winghead (a special species of hammerhead shark).

It is very new(no more than 2 months) and will take a long time for completion: it took me around 8 months for the previous project to be finished.

What I had in mind for this project:

- Try a different layout, but not too small either.

- Increase PCB functionality and complexity a bit to have new challenges.

- New case design of course.

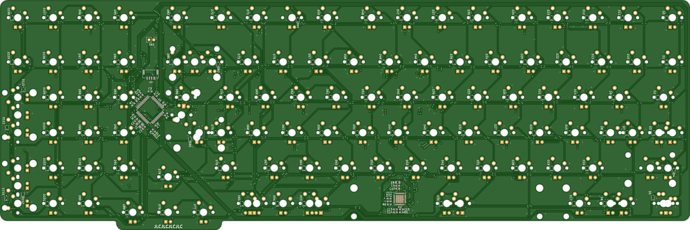

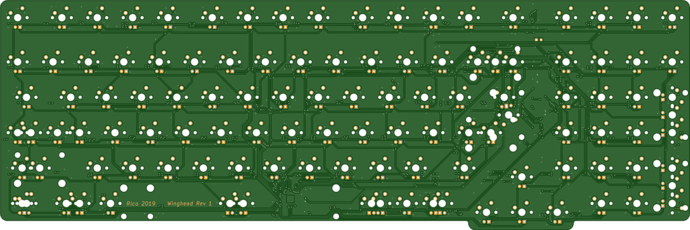

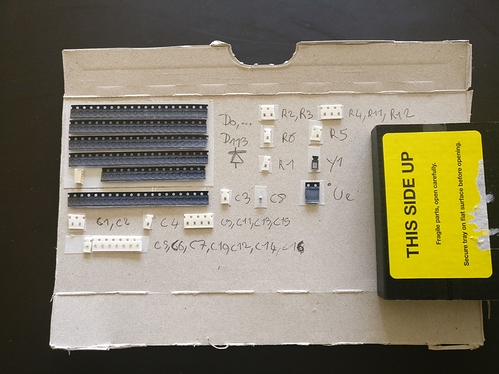

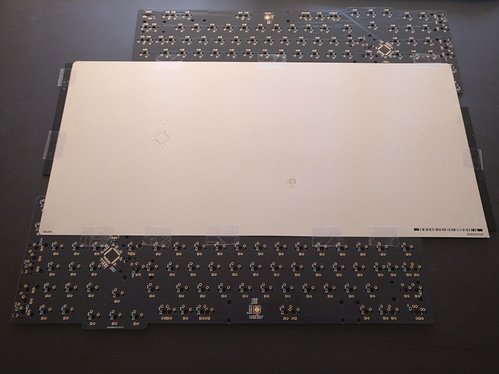

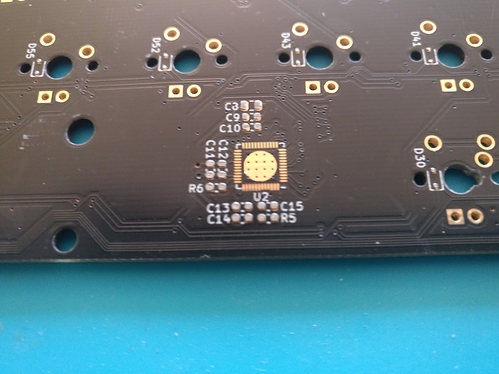

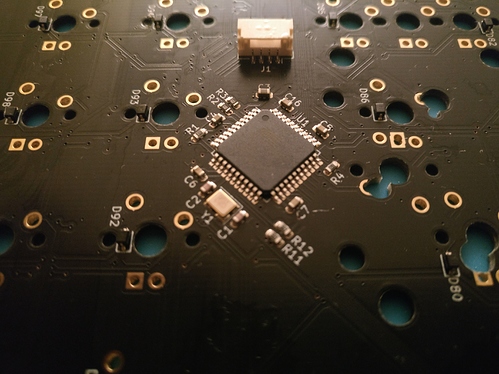

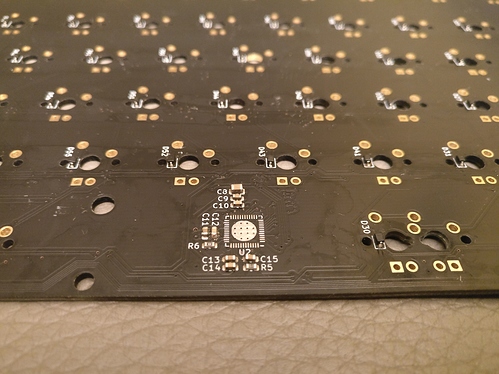

The PCB(s):

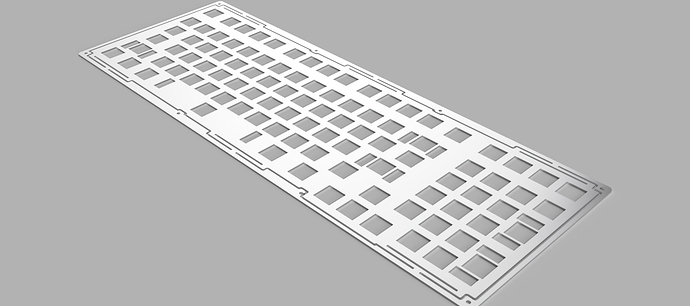

- No more hotswap sockets, simple soldered switches with plate and pcb mount compatibility.

- Goodbye Costar stabs, Cherry PCB mount stabs used instead.

- Increased layout customization, welcome to the PCB Swiss Cheese effect

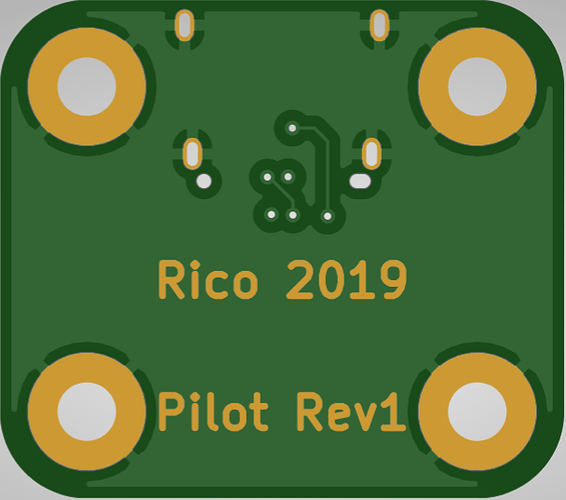

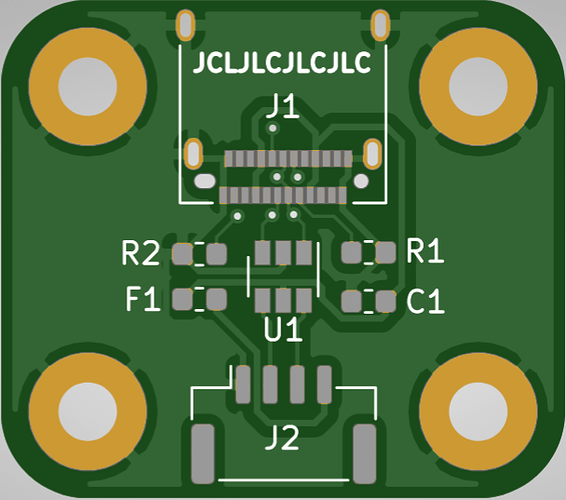

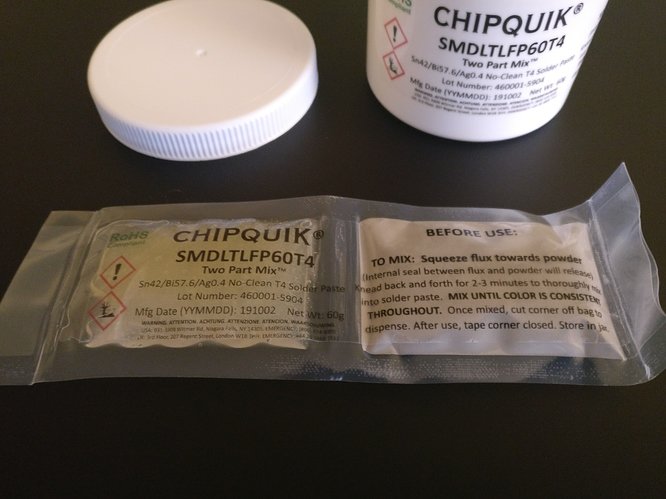

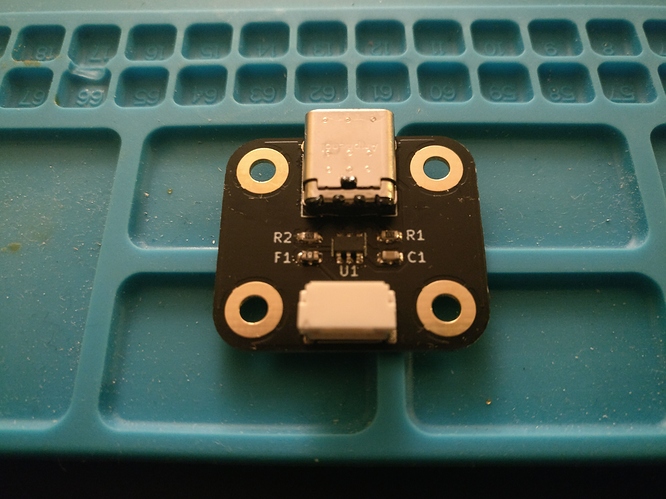

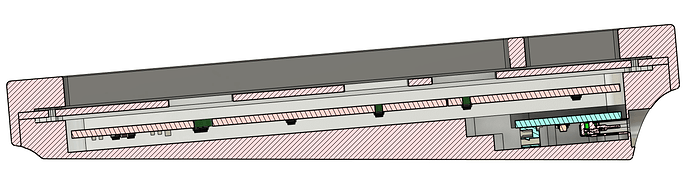

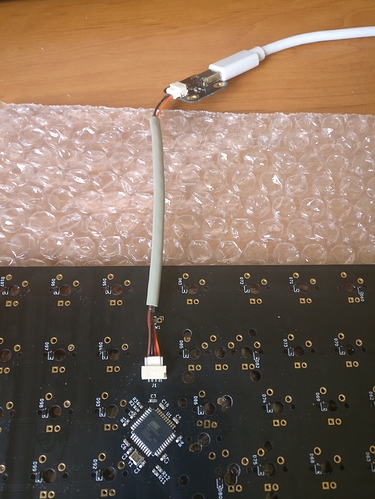

- Separate daugther board PCB with USB C, ESD and over current protection.

- No capslock/numlock/scrolllock led indicators to keep case design uncluttered.

- In-switch monochrome LED lighting, independently adressable.

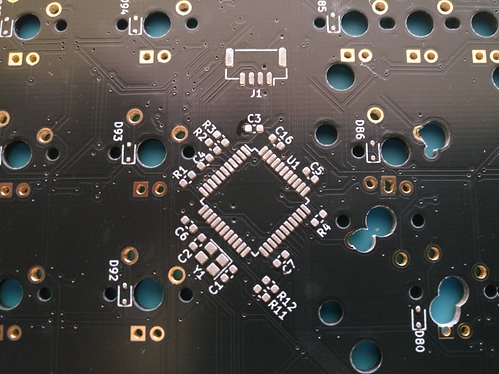

- ATMEGA32U4 MCU:

- Try to do more stuff with less available pins than the previous project that used an AT90USB1286 MCU.

- It is a funny personal challenge.

- Smaller package makes it easier to find a place in the PCB.

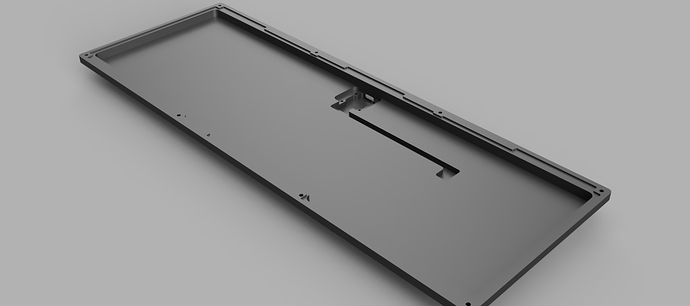

The case:

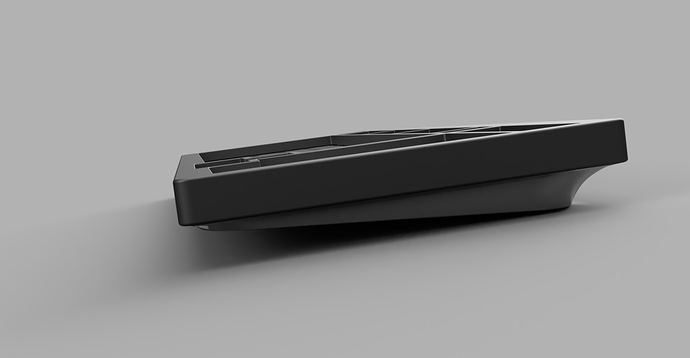

- Two parts design.

- All anodized aluminium.

- No integrated plate.

- So no brass or steel weights and no complicated design in order to lower price.

- Probably sandwitch plate design:

- I’d love to take inspiration from @Wilba’s work on spring plate design for it’s Thermal.

- Absolutely genious idea that he had, just watch @TaehaTypes build video and you will understand.

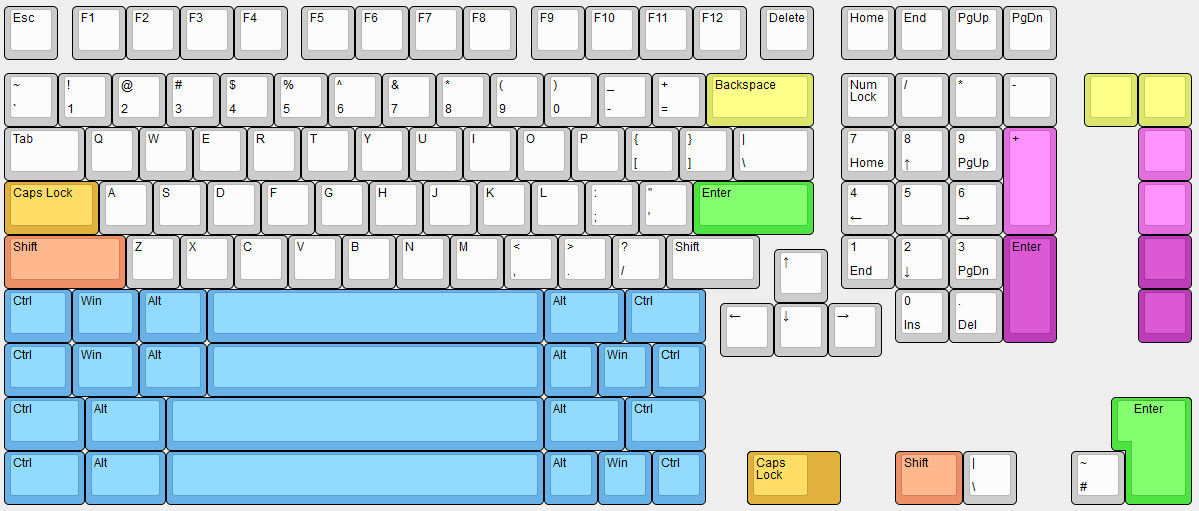

This will be a 1800 layout with the following compatibility:

Progress done:

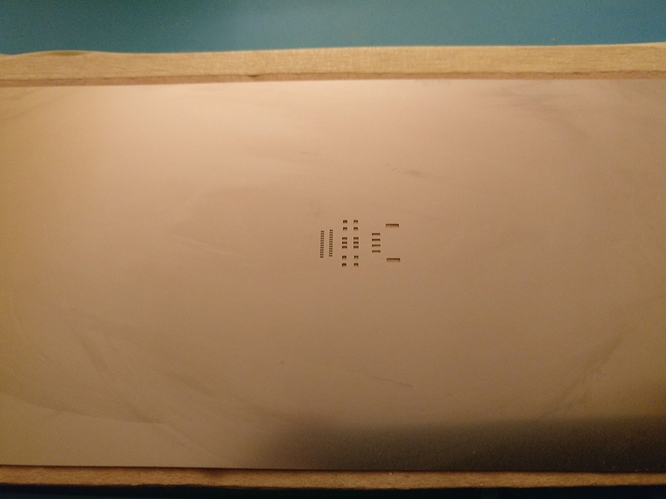

- PCB design well advanced, now tuning and double/triple/quadruple checking it.

- Draft case design, may change depending on plate design choice.

See you soon!

I did some basic tests with my multimeter, like:

I did some basic tests with my multimeter, like:

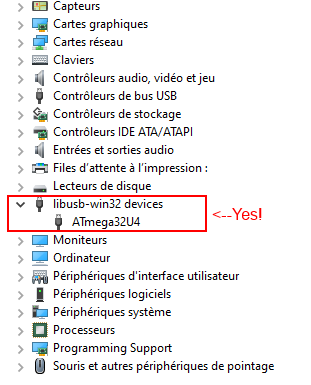

) I had this nice view on my device window

) I had this nice view on my device window