Imagine somebody milking r/mm with your RnD

I’ve no beef in the game other than as a hobby so more power to anyone who chooses to do it commercially. I do like the fact that there seems to be some market demand.

Scroll down to bottom for video of bruteforce polishing. Roughly twice a second, so around ~6hrs per batch. Not bad at all.

UPDATE: I do think the polishing machine can be improved by changing the pads to more grippy rubber and adding to backing of each pad some rods or asymmetrical balls that randomly push against the pad to tilt the angle. Intent of the design change is force stem to rub against sides of the housing rails.

Rumors I heard it ain’t good

Kudos for someone trying to commercialize breaking in switches. Fortunately this is a small community if it’s great bad or indifferent word gets around quick.

As someone who put some time into this. Direct pushes like this do work but not as much as you might think. I sent samples to DonPark to compare against various methods a while back and came to a similar results. It will definately make the switches smoother then stock but further noticeable improvements can be made with other methods including different actuation methods and additives such as diamond paste, toothpaste, DE etc.

It’s interesting that the reddit post also mentioned to keep the housings and stems together. This makes sense to me. I dumped all my switches together in an ultrasonic cleaner and was disappointed when reassembled.

Its been a while but last time I tried setting up a different actuation machine, yay more power tools, I messed up a batch of switches and keycaps (my fault too much power…). I think my problem was I should have stuck with keeping the plate on the sander side and used some foam to push the switches against, I also think a line of switches would be better then a grid. Will get back to testing around eventually.

Polishing a single switch using Diatoms+PG mix had mixed result. Switch felt smoother but still sounds scratchy. I think Diatoms takes longer to polish to satisfying smoothness than diamond paste. The powder is very fine so I’m going to try dry powder polishing next.

For now, thinking of using a brush to powder both housing and stem. Another options may be to use a blower. Just puffing some into a switch through the top with stem pressed made a switch extremely scratchy but I want an even coat. If you want to try as well, be sure to put on a google and a good mask.

Oh, I did some digging and I think chalk can also be used like diatoms for polishing.

Started polishing two more switches two different ways:

Dry polishing: This is result of just placing the tip of diatoms bottom on the switch top and puffing into it with stem pressed. I didn’t expect the coat of powder to be this good.

Wet polishing: This is with paste made from mixing diatoms with toothpaste (cheapest Arm & Hammer kind).

UPDATE: Neither turned out satisfying. Definitely smoother than stock but not as smooth as the first one I tried, Diatoms in PG. Dry polishing also made unbearable screeching sound. So I threw everything into one pot.

Then I dipped the stems. Bag lubing is another option but I already made a bottle of the magic sauce and dipping was easier than bagging. Polishing three switches this time.

KPS (Korean Polished Switch) Dipping Sauce Recipe:

- Diatoms (1tsp)

- Toothpaste (1tsp)

- PG (adjust amount to reach desired viscosity)

Viscosity should be such that stem dipped into it will be thickly and evenly coated, thick enough to fill gaps between the stem and the housing.

UPDATE2:

Actually, I used a brush to apply a thin coat on one of the three. That one came out pretty smooth after polishing. The other two were dipped and literally covered with the sauce and came out very smooth after polishing. I mean double-polishing level of smoothness in one shot. I think the difference was filling the gaps between the stem and the housing with abrasive.

So I recommend dipping over brushing or bagging (haven’t tried bagging yet so leaving it out). I think this will be my new polishing method since polishing twice is not smart when I can get the same result doing it once. A big thanks to @b00zled for suggesting diatoms+toothpaste combo. It’s working great!

If anyone has a batch of vintage blacks too scratchy to be used, let me know.

I don’t have the patience for r/mechmarket. Every time check, all I can find are already sold too-good-to-be-true postings or unreasonable prices.

Why do you want vint blacks over the modern blacks if you polish them anyway?

Are there any links on amazon for the components?

Because I want to see if vints sound better than retooled. AFAIK, sound quality is:

vintage black > hyperglide black > retooled black.

Re components:

- Diatoms Amazon.com

- Toothpaste Amazon.com

- PG Amazon.com

Because they are all very close in materials and design, should be a miniscule difference, if at all.

Also Mr Don can you tell me how you are polishing it in detail? I want to get the same results as you using the same procedure.

I am just pushing the stem and housing together with great force, with abrasive on the friction/ contact points.

When polishing, I alternate between two modes:

- while I’m reading, I roll a pair of silicone balls over naked switches nestling in a 60% plastic Poker case with hot-swap PCB and aluminum plate. Not having the keycaps on allows balls to push stems to the side more.

- while I’m coding, I flop the board face down under the desk and pedal it with both feet. Playing some toe-tapping music helps.

Hello everyone! Here is my process using diamond paste that works 100% of the time, guaranteed smoothness and all that stuff. I am using Novelkeys’ new batch of Cherry clear (very scratchy)

date: Thursday April 8 2021

I don’t know if the photos will work, but I will try my best to show what’s going on

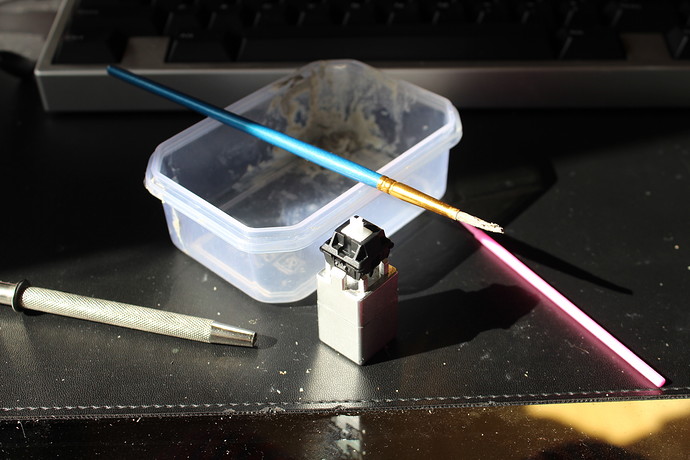

Here is my setup: Paint brush, pink microapplicator, jewelry tool (stem holder),

The microapplicator is used to remove factory lubrication from the switch leaf.

The paint brush is used to spread diamond paste over the stem.

The jewelry holder is used to hold the stem in place when applying paste and also to “break in” switches after pasting.

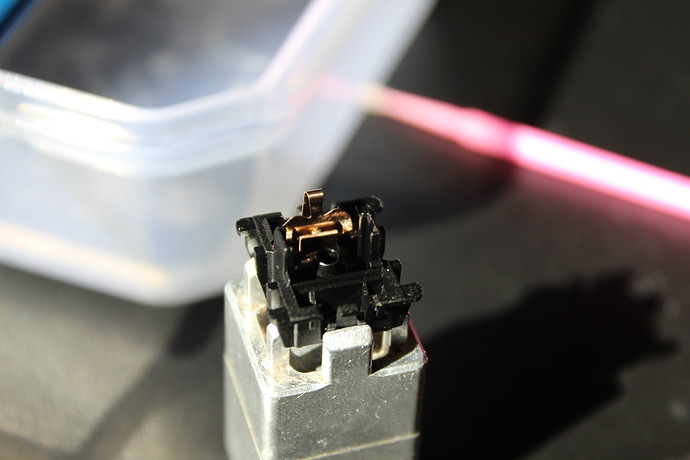

Above: factory lube on the contacts (Use microapplicator to remove)

Important: Apply a small amount of paste to the leaf “bump” before continuing on stem.

This ensures even coverage of the highest friction points.

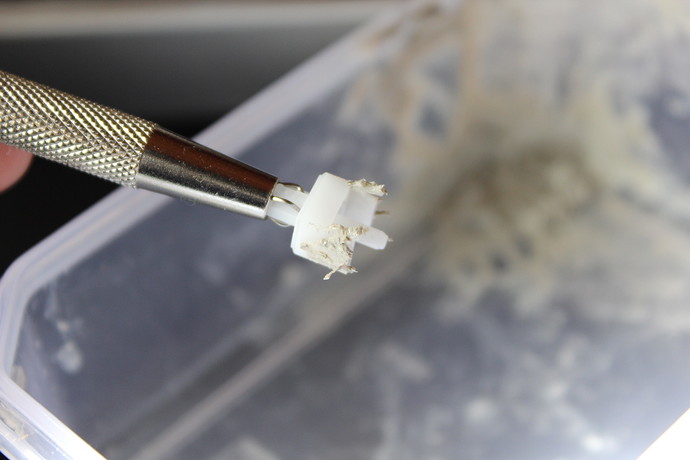

After you have removed the factory lubricant, you can use the diamond paste on the stem as shown. Mix with a couple drops of water to ensure easier application, but do not soak the paste in water.

Try to use as little water as possible.

The paste is on the stem rails as well as the legs.

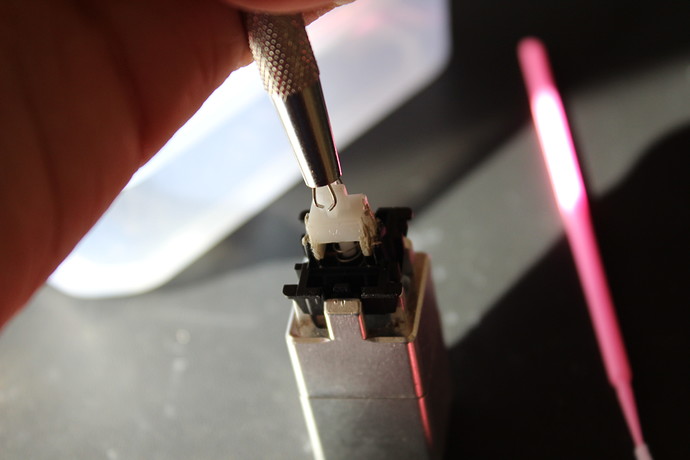

Use stem holder to push stem back and forth to spread the paste around. You should feel the friction as the stem torques against the housing.

I do not polish the switch top housings because they have minimal effect on the smoothness of a switch.

This approach is consistent and works every time. It takes at least 2 minutes per switch, but is definitely worth it.

Sincerely,

treeleaf

Aha. So you’re polishing the stem directly with top housing removed for 2 minutes, rubbing the stem against the contact leaf and sides. Thanks for sharing this interesting way to polish.

The whole thing (opening, removing lube, applying paste, actuating switch) takes around 2 minutes, if not more. If it’s not as smooth as i like then I will reapply some more paste and keep rubbing.

I find it very annoying to apply the undiluted paste

By the way, is there a place to get hyperglides that are not factory lubed?

Nope. Just small circles inside a bigger circle. Polishing itself is annoying. But having to polish these switches enhance my enjoyment of them. If could just buy them off the shelf, I’d be more focused on what’s wrong with them.

Has anyone tried using other compounds for polishing? Just love this thread! Was literally thinking of doing this, and I’m so glad to see that there are fellow enthusiasts who’ve already experimented on this idea!

Some compounds I’m thinking of doing experiments with:

-

Tamiya Polishing Compound (not sure if this would be as effective in cutting as TEMO Diamond Paste, but I think it’ll be safer in terms of not leaving any diamond dust residue in the plastic. There are 3 grits available still not sure which grit to choose)

-

Polywatch Plastic Polish (generally used for removing scratches on plastic, mineral glass, hesalite or any non-sapphire glass face on watches. It takes out hairline scratches in an instant)

Any opinions on these?

Yup. We’ve been testing diatomaceous earth mixed with toothpaste and PG. Pretty good result so far. Thanks for suggesting Tamiya Polishing Compound and Polywatch Plastic Polish. I’ll try them in the future.