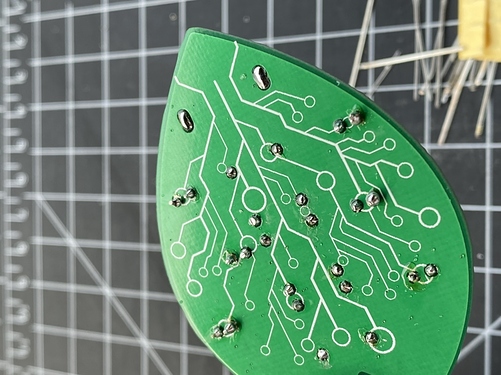

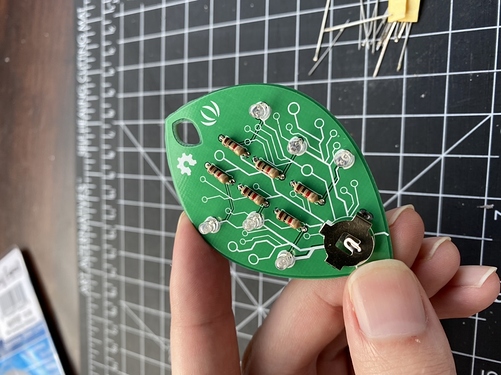

TIL to solder! Feels like this has taken a while - researching tools, ordering them, learning, and finally trying it. And realizing I’m totally a beginner at this. I had some great joints and some pretty bad joints. Definitely glad I used the practice kit first, and not any of my keyboards pcbs. I need a LOT more practice. Learned a lot tho trying it for real. Starting to get a feel for it.

Shout out to @CosmicKira for the video series in this post:

Soldering Video Series From PACE

I learned so much from these. Still a couple to finish on the repair/damage video list. But it was awesome. That narration… The diagrams… The intro beats… I feel so educated.

I was actually better at soldering than desoldering. I had a solder sucker for this and the snap back was so sharp I had trouble keeping it in place while trying to heat the spot. It was a disaster. Anyone have advice for desoldering cleanly? Do I just need more practice? I suppose I could invest in one of those high end extractors, but that seems a like a lot to spend on. (Need to save that for more boards lol)