The Alps Wyse clone I won on eBay has been occupying more of my mindspace than it really ought to. I had to take it apart and then run FCC searches to see that it’s a whitelabel design made by Costar in the 90s. It has Alps blacks (bamboo era), which I will absolutely be linearizing, because even as someone who tends more towards clicky and some tactiles, these things are pretty scratchy; good weight though. It has a PS/2 plug, and while a few keys send odd scan codes and a couple aren’t registering on a simple Soarers layout, the board mostly already works fine and shouldn’t require a ton of work on the software front.

The bigger issue is the keycaps. They’re just so ugly. The ABS is a bit more yellowed than the case (and less consistently so, which may be worse), and whatever technique they used for the legends (early lasering, I think?) has resulted in a fuzzy mess. I have had up and down moments with my laser legends in the last year, but these are not better than what I can do with PBT. Unfortunately, there is no DCS SMRT for Alps mount, lol, nor do 9.75u spacebars grow on trees.

This is going to require either accepting what I can’t change, or a new level of stupid. While I will go easy on the existing caps so they’ll be there in their sad but usable state, a new level of stupid sounds like fun, at least after I’m done with the current Alps project. Eventually I think I’ll try printing the adapters that are out there, but pairing them with low-profile caps so the overall height doesn’t get away from me, then maybe experiment with some sort of internal riser or standoffs for the top case to make up some of the aesthetic difference. I’d also need to get pretty creative with wire-bending to try to get a geometry that allow Costar cap inserts to mate with Alps plate clips. As for the spacebar… well….

clone Wyse

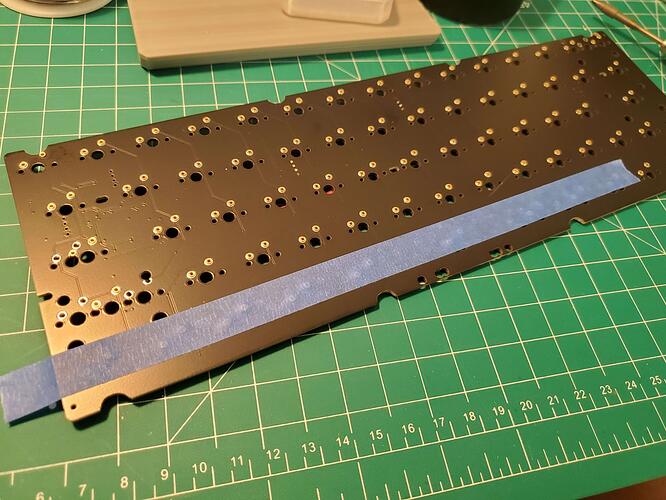

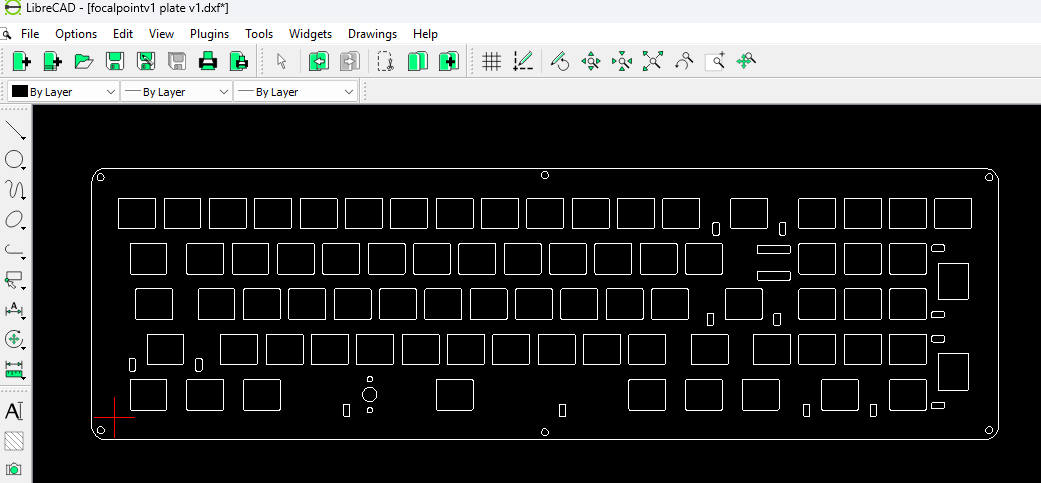

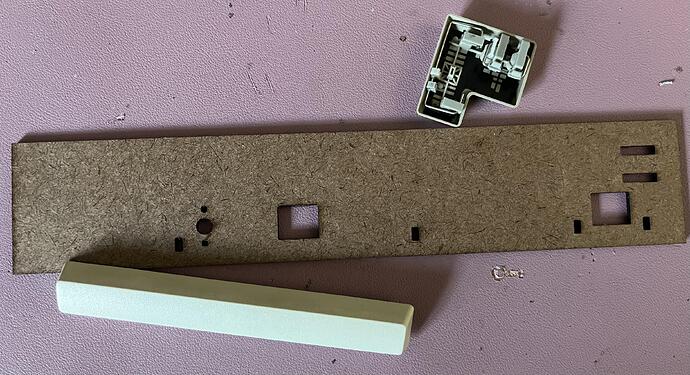

As for the wooden-case project, I’ve soldered all the diodes, resistors, and headers on, as well as the first of what I expect to be four bodge wires. Next is to cut the plate and make sure everything lines up. I will probably be firing up the ol’ glue gun to make sure the Alps stab clips stay where they need to be. If I ever do an MX version with my spare circuit boards, the PCB clip-ins are starting to feel like a mighty nice idea. It’s enough to make a guy wonder why he got away from no-stabs boards at all.

Solderin’

Speaking of no-stabs, I came up with a weird but potentially usable 70%-like layout for my older PCB design, and it still wouldn’t need true stabilizers. Did you know that the switches for two 1.25u keys are in the exact location as the mounts for a 2u stabilizer? This is not usually super useful, as 2u keycap won’t fit, and only a 2.5u cap (does this exist?) would slot in perfectly,. Anything else kind of jacks up the rest of the row by requiring it to sit on 1/8u spacing, but if you’re going for a vintage or type-writery feel with some pretty substantial blockers, both 2.25u and 2.75 are adequately stabilized by a dummy switch, and would allow one key on either side. My current build would be damn near unusable with a double-box-navy spacebar, but a lighter switch in a stable housing should work more than well enough as a “post style” stabilizer.

Cursed KLE