i might need me some PTFE tape too…sounds great.

I made a stand for “The Big Switch”. Seems like they should include something like this or somehow make the box able to become the stand. At any rate, it gave me an opportunity to design something up and print out.

https://www.prusaprinters.org/prints/99303-the-big-switch-stand

Enjoy!

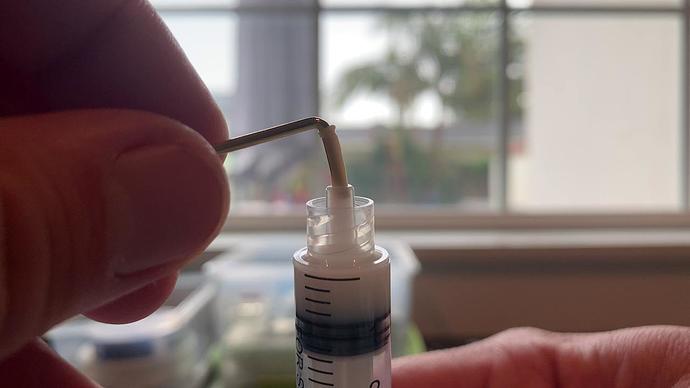

A slightly easier way to lube them wires. If you’d prefer a thicker coating, I’m thinking you could just use a bigger gauge syringe.

All you got to do here is ease some pressure on the plunger and let hydraulics do it’s thing. The wire glides right out with a consistent coating proportionate to the gap between the wire and syringe tip.

thats genius =D Thanks for sharing

I should call her…

The silencing of the Frogs, plus a bit of experimentation. I was going to put these in my Kara yesterday but the pinging was so bad I had to shelve them and go with Nixdorks instead. I wanted to solve:

- Was it spring or leaf ping?

- If spring, could it be solved with donut dipping?

- Adding another variable, does plain Krytox 205g2 work for spring dipping? It’s thicker than anything I’d lube a switch with but seems like a good candidate for this.

After some playing with the switches, it was definitely spring ping. Not consistent across all switches but the bad ones were truly horrible. Even just tapping the side of the switch housing would produce a soft pong sound. Same when opening the switches - a loud pong pong as the top housing clasps released.

Luckily, the results with the Krytox dipping were positive. More material is used in comparison to say, bag lubing but I feel fairly comfortable that this’ll be a permanent fix so I’m happy. Krytox also works well for donut dipping; the worst of the batch definitely need a bit more on the base to quiet down but it’s definitely doable. It’s slightly less compliant to work with than Gazzew’s blend but it’s definitely still feasible. I’d say that the process removes around 90% of the noise so even the loudest among them are thankfully now usable. I’d call that a result!

I don’t recall any spring ping in my frogs, but I purchased them a while back. I wonder if they switched to a new source for springs.

I’m still hopeful that these were a fluke. I’m leaving them stock outside of the remedial work on the springs for now as I’ve heard such good things about them. I’ll finish them up tomorrow and then they’ll be next in line for the Kara.

I officially hate stabs. I spent the entire day working on my KBDfans ones that came with the KBD67Lite… It’s purchase after purchase with keeb stuff and I think I need to chill it for the rest of this month until I get some of my courage back.

Damn you, ticking!

Breh I feel this.

KBDfans stabs aren’t bad per-se, but they are quite difficult to silence.

I 100% feel this. Cant ever get my stabs quite right no matter how much lube or bandaids I use. Getting some PTFE Tape so I hope that helps

Now that I have some, I can’t imagine doing a build without PTFE tape on-hand. It’s good for so many things, including multiple parts of stabs. ( Edit; I used some today. )

Another essential, which at the moment isn’t the easiest to find, would be “North-facing compatibility washers” - essentially ring shims of a very specific size and thickness that are fantastic not only for keycap compatibility on upside-down switches, but very useful for dialing-in stabs. This is especially true in builds that feature reduced-travel switches, which are more popular than ever. The shims can help balance a stubborn space bar in general, but also prevent it from teetering on a long pole, for example. (I also used these in the post I linked in the first paragraph.)

I settled on doing a half Holee (big ramp) using a suitable slick adhesive and Nyogel, on only the part of the wire that actually goes into the slider, applied with a wide tip syringe. Everything else is lubed per usual.

This tamed some gnarly tick on the KBD stabs I got with the Lite R2.

Taping only the big ramp allowed me to go with a slightly thicker tape that helped equalize the small bend the spacebar stab wire had on the left side. I thought of straightening it prior, but my aim was to go with a mod capable of dealing with these inherit defects without additional steps.

The Nyogel prevents the slider from having much movement outside what it needs to actuate. @donpark found this cool demo of what I mean …

I can’t stress enough how less is more with that stuff and that there is a small “break in” period after application. You can speed things up by rocking the sliders back-and-forth in the housing while in the down position. The tick is eliminated by the big ramp tape and how Nyogel works.

The downside is how muted the upstroke sound becomes and actuation will feel heavier than any of your other keys.

Just finished lubing and tuning my partner’s FC980M. She wanted purple but there weren’t too many good options until NK came out with this set. Lubed the Cherry Blacks and Stabs. Considering a Heavy-9 in K2 for this to really elevate the keyboard but that’s a pretty pricey upgrade. We’ll see how she likes the new improvements this week

767a seems like it might be a bit too viscous. Maybe 760g?

Nye has a page for dampening grease which seems like what stab wires need for sure Damping - Nye Lubricants

But I ain’t no industrial engineer

I use the 767A variant. It’s very viscous. I haven’t tried any of the others yet.

I just wanted to share a hotswap issue I had where the 8-key wasn’t registering even after confirming the switch pins weren’t bent. I assumed it was a dead switch but none of my working ones made any difference.

I inspected the pads and those hadn’t popped, so the head scratching began …

I noticed the pad’s right connection was a bit spacious and probably not making any contact with the right switch pin. The MacGyver approach I went with was just to twist the switch’s right pin so it was a bit vertically askew and allowing contact to be made. It might be time for a new tester.